Movable cutting edge mechanism of progressive stamping die

A movable and progressive die technology, applied in the field of electronic parts manufacturing equipment, can solve problems affecting product size, product use, punching step difference, etc., and achieve the effect of improving production efficiency, reducing machine tables, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

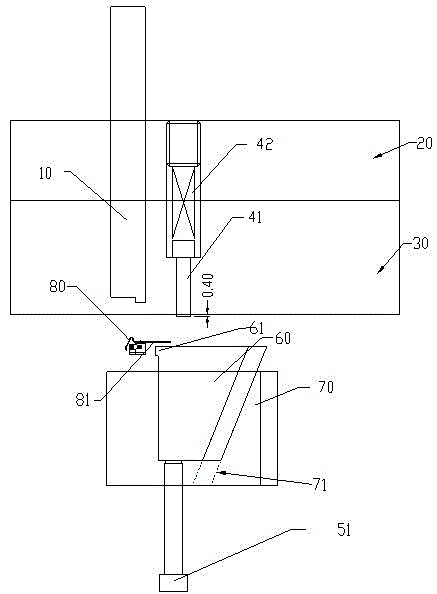

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] see image 3 , the embodiment of the present invention includes:

[0020] A movable knife-edge mechanism of a stamping progressive die, comprising: punching punch 10, middle die backing plate 20, middle template 30, upper die ejector pin 41, upper reset structure 42, lower die ejector pin 51, lower reset structure, Slider 60 and slider seat 70.

[0021] The middle mold backing plate 20 is connected to the middle formwork 30, the upper end of the upper mold ejector pin 41 is connected to the upper reset structure 42, and is installed in the middle mold backing plate 20 and the middle formwork 30, and the upper mold top The upper end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap