Bead ring positioning, clamping and turning device of bead ring winding machine

A wire ring winding machine, positioning and clamping technology, which is applied in the direction of manufacturing rings, other household appliances, household appliances, etc. from wires, to achieve the effects of easy production, improved durability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

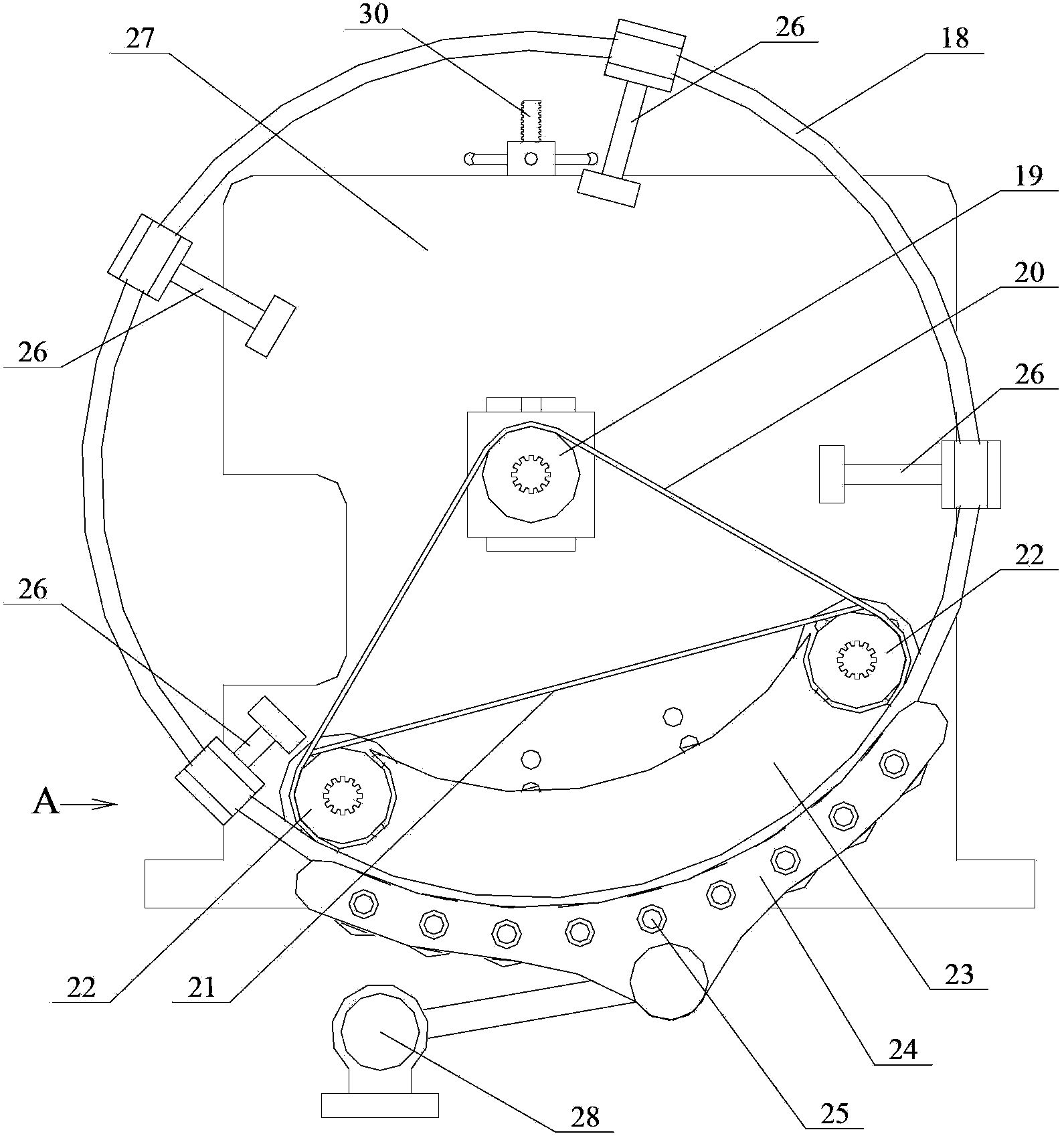

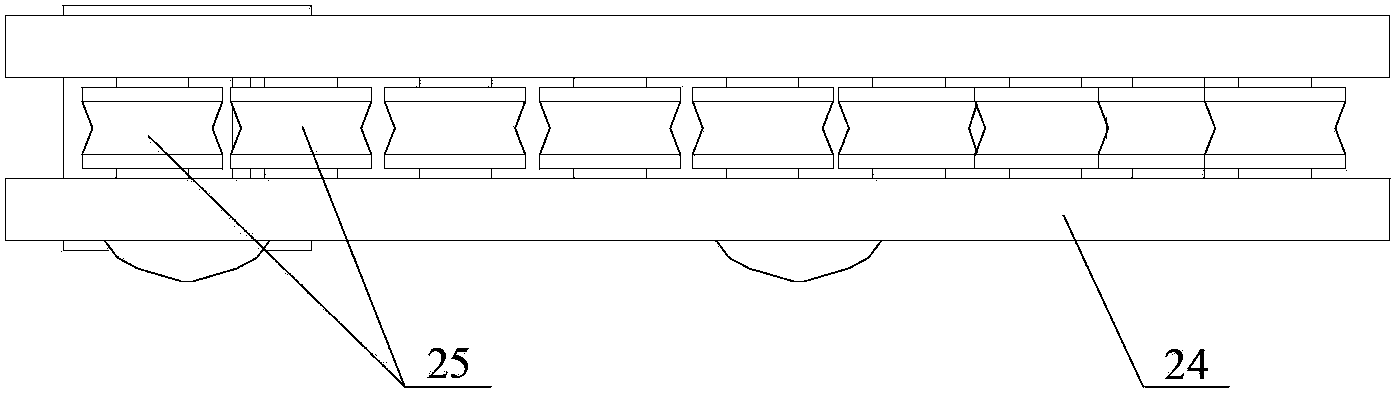

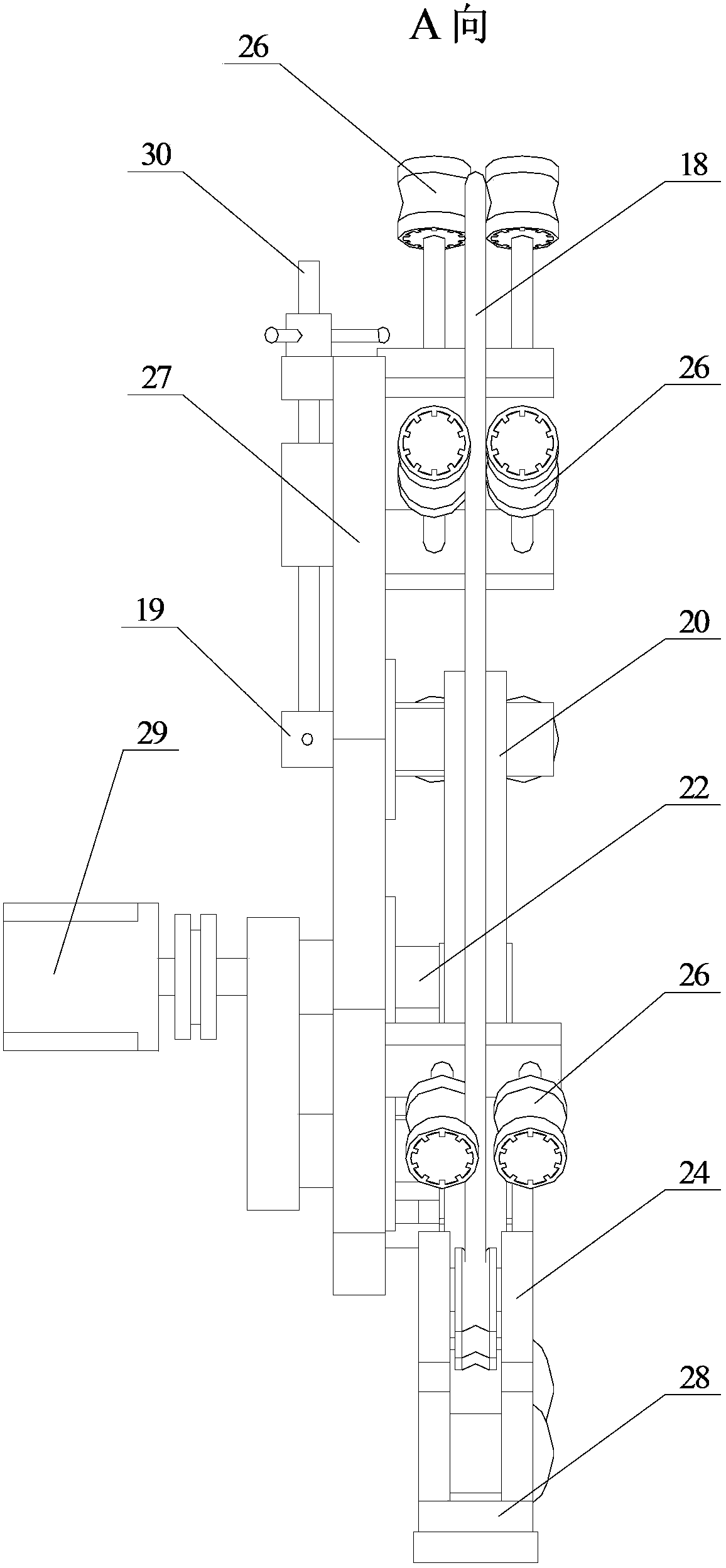

[0017] Such as Figure 1 ~ Figure 3 As shown, the traveler positioning, clamping and rotating device of a traveler winding machine involved in this embodiment includes: a center roller 19, a steel belt 20 with rubber attached to the surface, a toothed belt 21, two transmission rollers 22, an arc Shaped steel plate 23, pinch roll stand 24, pinch roll 25, three pairs or four pairs of auxiliary rolls 26, rear panel 27, hydraulic cylinder 28, drive roller drive motor 29 and lifting lead screw 30, the three or four pairs The auxiliary roller 26 is arranged on the back machine plate 27, the arc steel plate 23 is fixed on the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com