Flat milling machine

A flat milling machine and flat milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve problems such as low efficiency and poor quality, and achieve the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

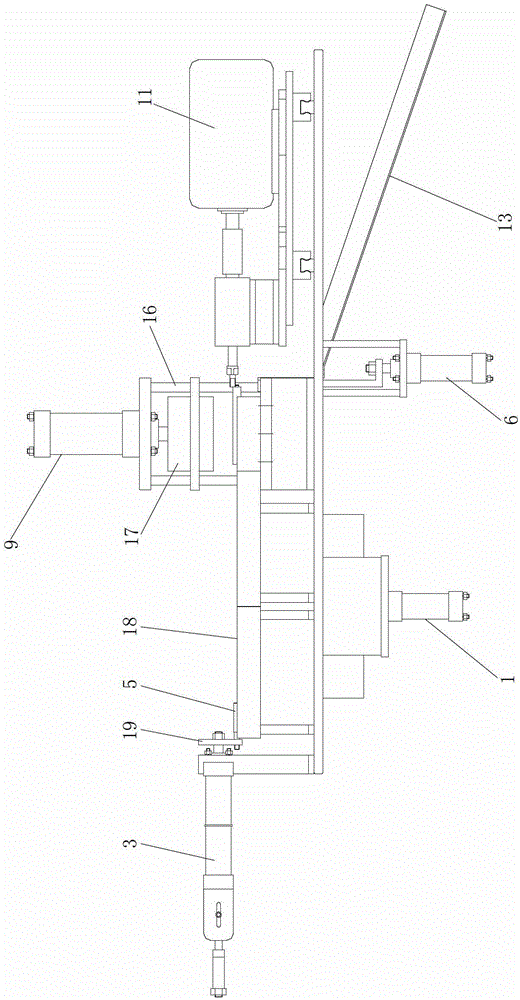

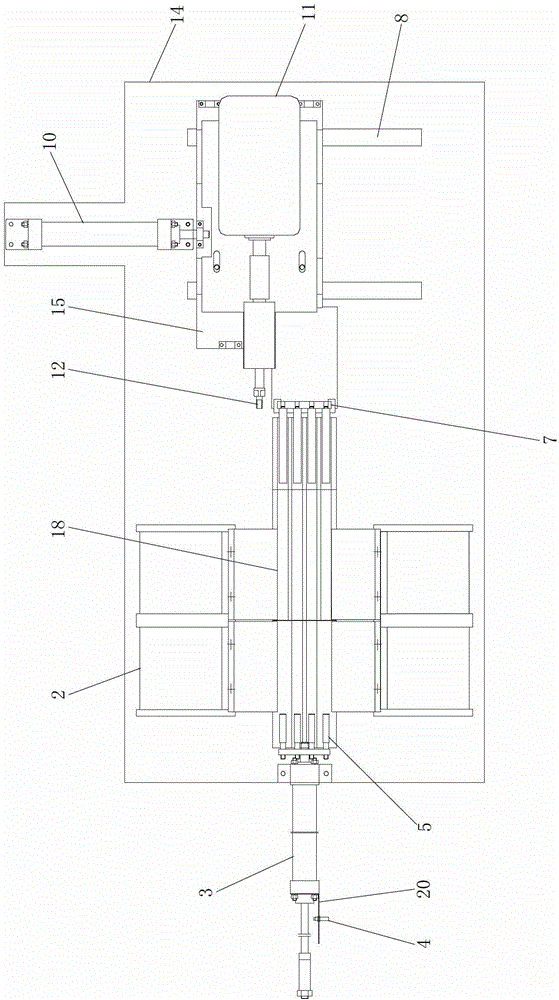

[0017] refer to figure 1 and figure 2 , The milling and flattening machine of the present invention is sequentially provided with guide rails, telescopic positioning devices, pressing devices, automatic feeding devices and discharge channels along the length direction of the workbench. Each part is described in detail below:

[0018] refer to figure 1 and figure 2 , the guide rail 8 is perpendicular to the length direction of the workbench 14, a support 15 is slidably matched on the guide rail 8, a motor 11 is fixed on the support, the output end of the motor is connected with a milling cutter head 12, and the upper table of the workbench is provided with There is a milling and flattening oil cylinder 10 axially parallel to the guide rail, and the piston rod of the milling and flattening oil cylinder is fixedly connected with a bearing 15 . The working process of this part is: the motor 11 works to drive the milling head 12 to rotate, and the milling head mills the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com