Steel wheel assembling mechanical arm

A technology of manipulators and steel wheels, applied in the field of machinery, can solve problems such as complex assembly and high safety hazards of flipping, and achieve the effects of improving working time efficiency, solving assembly bottlenecks, and tightening the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

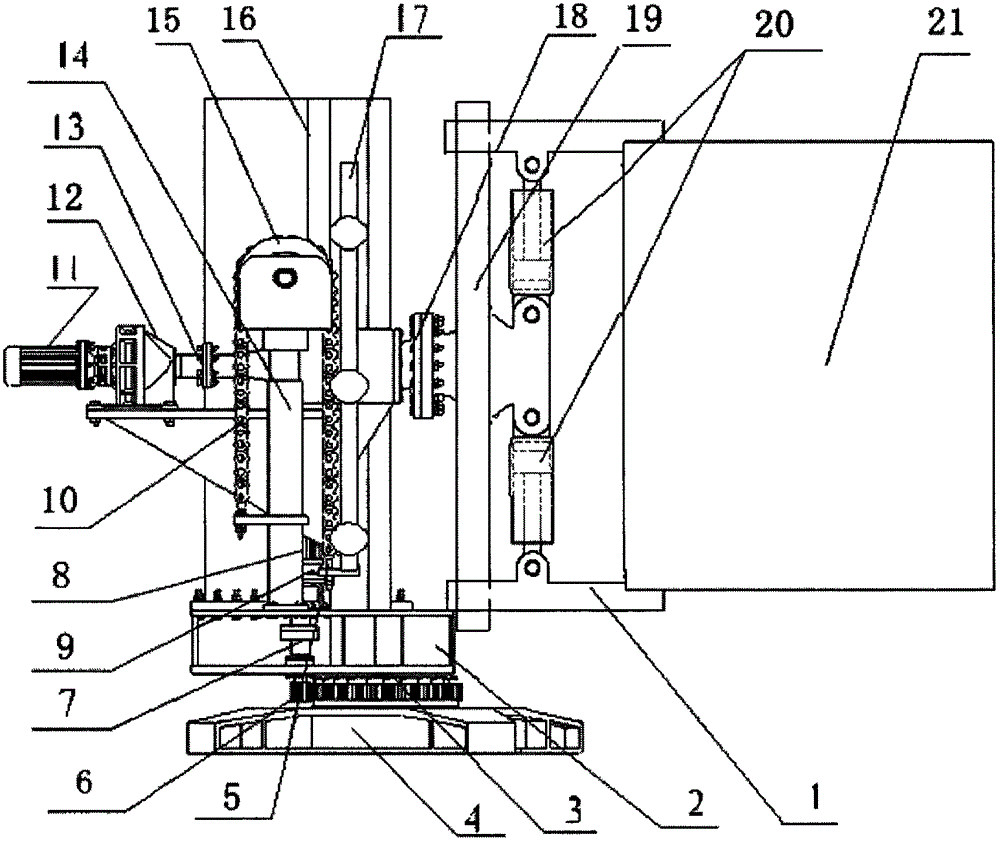

[0017] by figure 1 It can be seen that the slewing device includes a gantry 16, a slewing frame 2, a slewing support 3, a gear shaft 6, a slewing motor 8, and a first coupling 7. The gantry 16, the slewing frame 2, and the slewing support 3 are sequentially connected and placed On the base 4; the slewing motor 8 and the first coupling 7 are arranged on the slewing frame 2; the slewing support 3 is provided with a gear shaft 6; the coupling 7 and the gear shaft 6 are connected.

[0018] The turning device is arranged on the gantry 16, and includes turning motor 11, reducer 12, second coupling 13, flange shaft 18, turning frame 19, grasping cylinder 20, grasping rod 1; turning motor 11, reducer 12, The second coupling 13, the flange shaft 18, the turning frame 19, and the grasping rod 1 are sequentially connected; the grasping oil cylinder 20 is arranged on the turning frame 19 and is connected to the grasping rod 1.

[0019] The lifting device includes a lifting cylinder 14, a spro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com