Foldable stacking cargo tank

A stacking and cargo box technology, applied in the field of foldable containers, can solve the problems of not easy to use stacking sockets, not easy to align, stacking, easy to generate danger, etc., and achieves simple structure, good clamping effect, not easy The effect of coming out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, "above" and "below" both refer to the relative direction of the height of the cargo box 100 when it is placed on the ground, and "outside" refers to placing the cargo box on the ground to observe the cargo box The side that can be seen directly at the time.

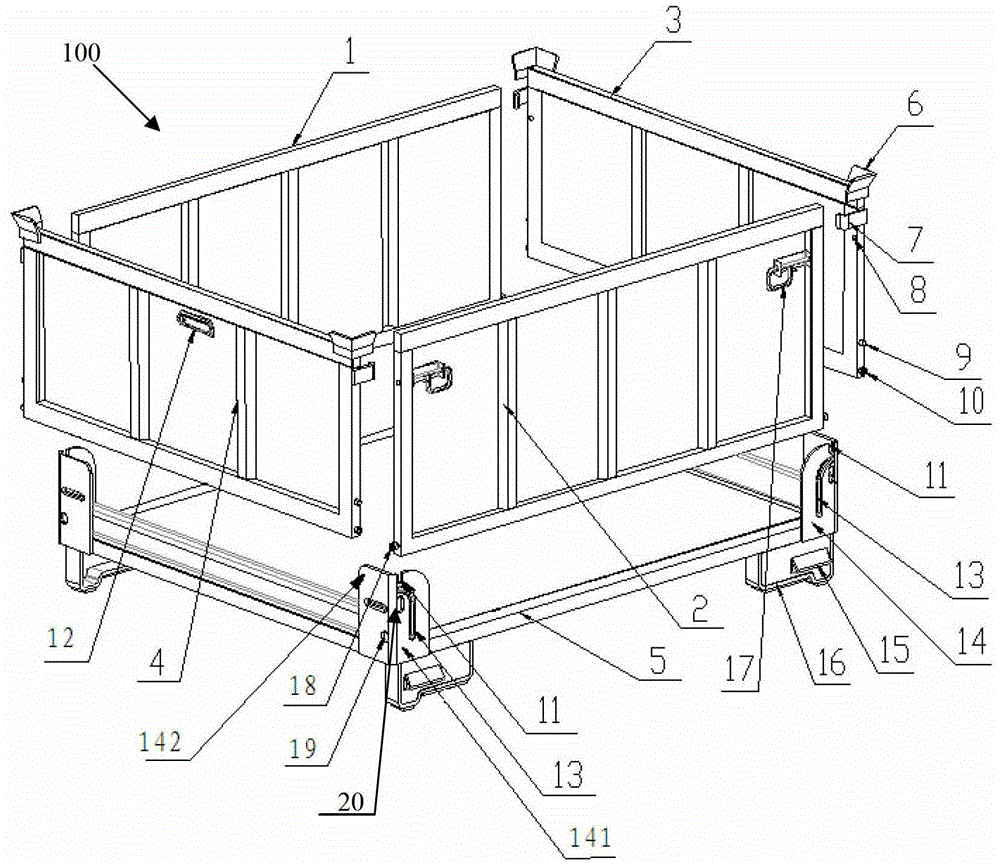

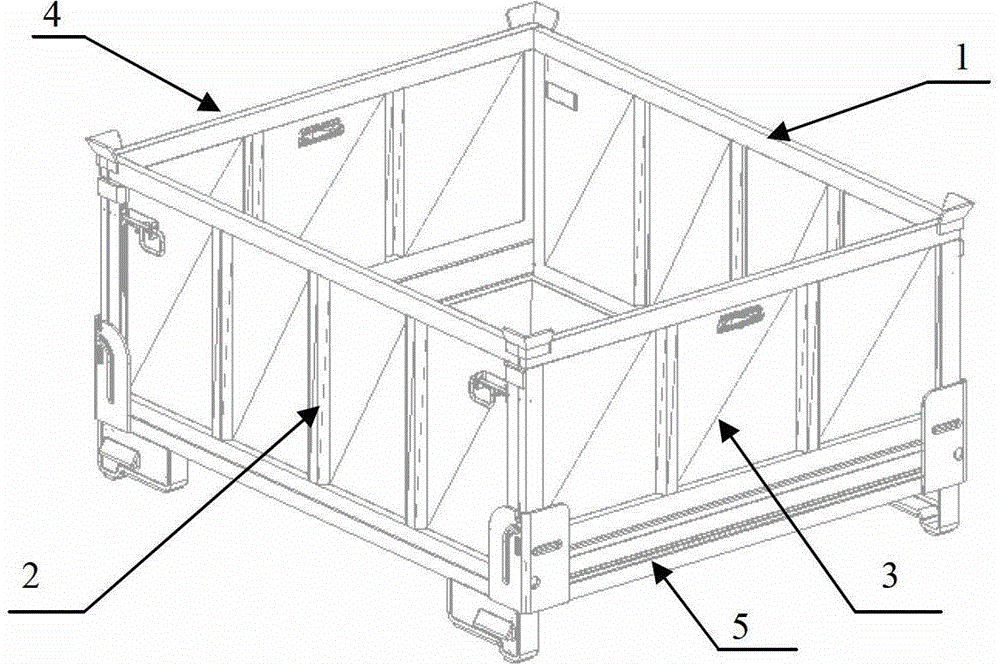

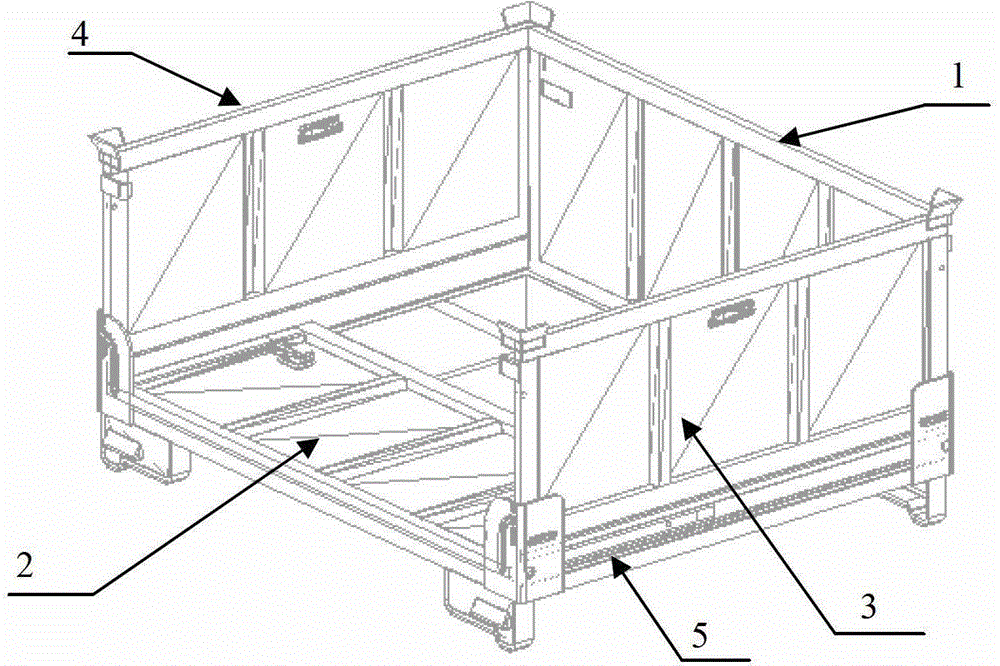

[0038] refer to figure 1, the foldable stacking container 100 includes a front side wall 1 , a rear side wall 2 , a left side wall 3 , a right side wall 4 and a base plate 5 . At the four corners below the base plate 5, four feet 16 are installed to support the base plate 5 and the entire container 100. The outer sides of the feet 16 form obliquely downward protruding clips through sheet metal stamping process or welding. The board 15 preferably adopts the technology that the seat legs 16 and the clamping board 15 are integrally formed with sheet metal, so as to save steps. The corner-wrapped board 14 is fixedly installed at the four corners of the base plate 5 , and the corner-wrapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com