Glass-based biomimetic micro-nano channel and manufacturing method thereof

A micro-channel and channel technology, applied in glass manufacturing equipment, separation methods, glass molding, etc., can solve the problems of large flow resistance, uneven rigid surface, and single size, and achieve high processing accuracy, simple equipment, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

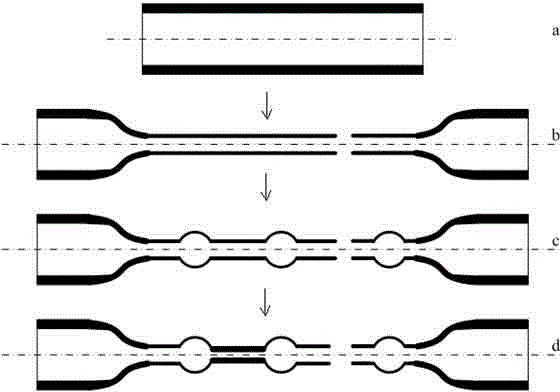

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

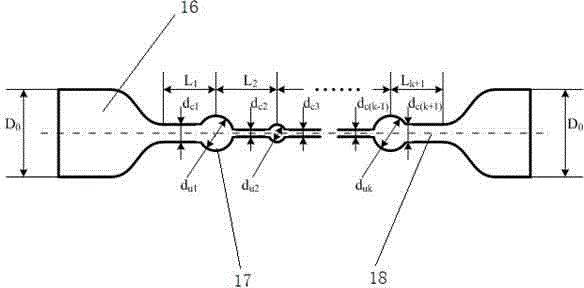

[0023] Such as figure 1 As shown, a glass-based biomimetic micro-nano channel of the present invention, the micro-nano channel is a micro-nano channel with the characteristics and performance of a biological micro-channel processed from a glass material with uniform components and excellent optical and mechanical properties , the cross-section of the micro-nano channel is regular and circular, and there are functional units of various sizes on the micro-nano channel. There is a natural transition between each functional unit and the size changes continuously.

[0024] In this embodiment, the glass material can be selected from various types of components such as quartz glass, borosilicate glass, and lead silicate glass.

[0025] In the present invention, the functional unit includes a macro interface 16 at both ends, a reaction chamber 17, and a connecting channel 18....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com