Method for drawing quartz glass rod by coreless rod through continuous melting method

A technology of quartz glass rods and coreless rods, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of small size of quartz glass rods and failure to meet the quality requirements of semiconductors and integrated circuits, and the method of achieving is reasonable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

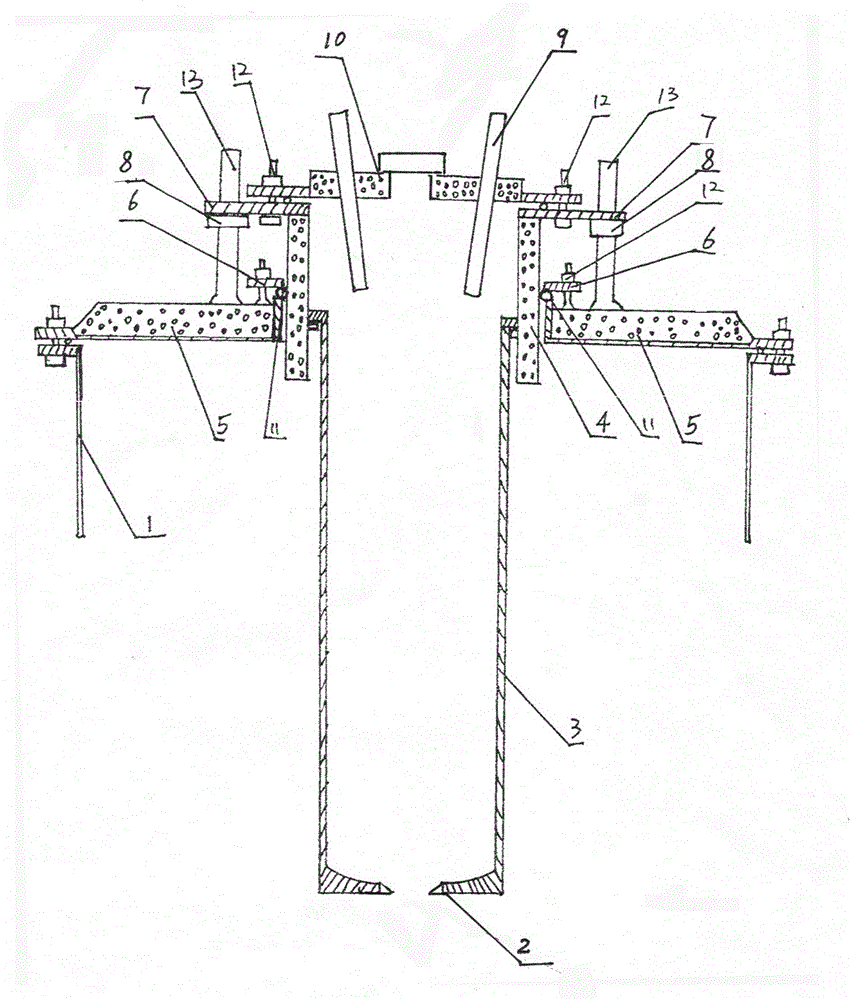

[0011] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0012] refer to figure 1 , a method for drawing quartz glass rods without a core rod by continuous melting, comprising a continuous melting furnace, the continuous melting furnace is provided with a furnace body 1, a tungsten-molybdenum crucible 3 is arranged in the furnace body 1, and a material table 2 is arranged at the bottom of the tungsten-molybdenum crucible 3, There is a discharge port on the material table 2, and the upper surface of the material table 2 is set obliquely downward from the inner wall of the tungsten-molybdenum crucible 3 to the discharge port, so that the downward speed and flow rate of the quartz glass rod can be effectively controlled, thereby adjusting the quartz glass rod. The diameter of the glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com