Take-up device and method for heat treatment of bead wires

A wire take-up device and bead steel wire technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to observe the surface quality of steel wires, disordered equipment investment, and complicated maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

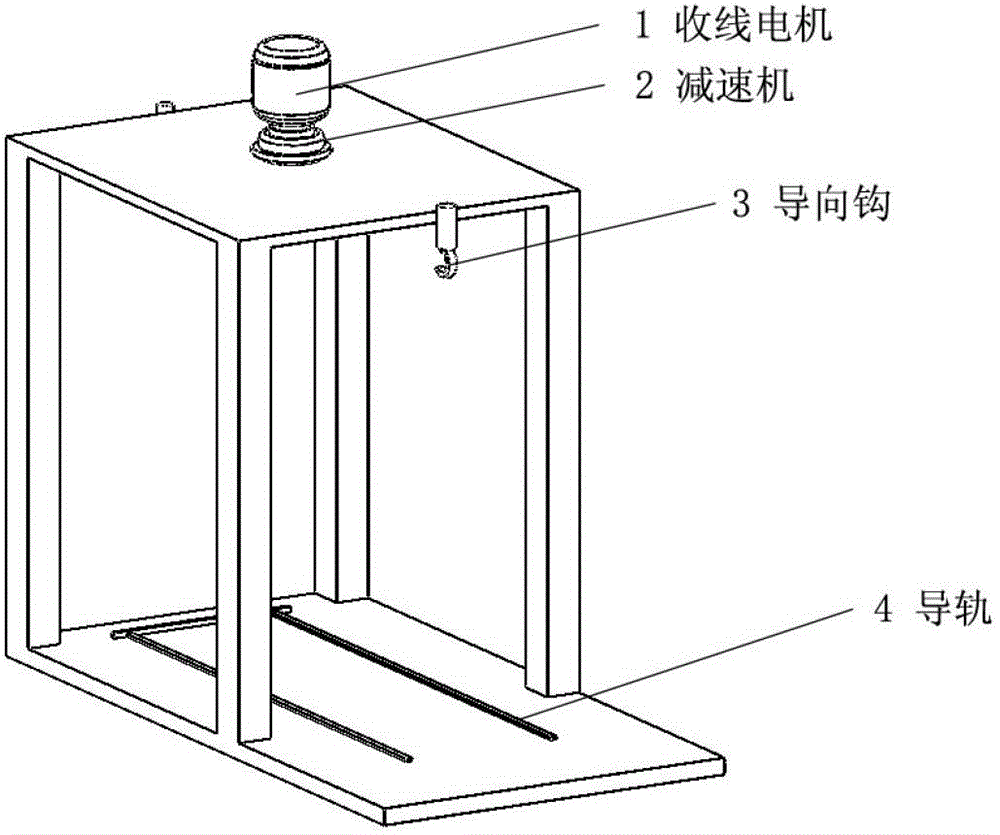

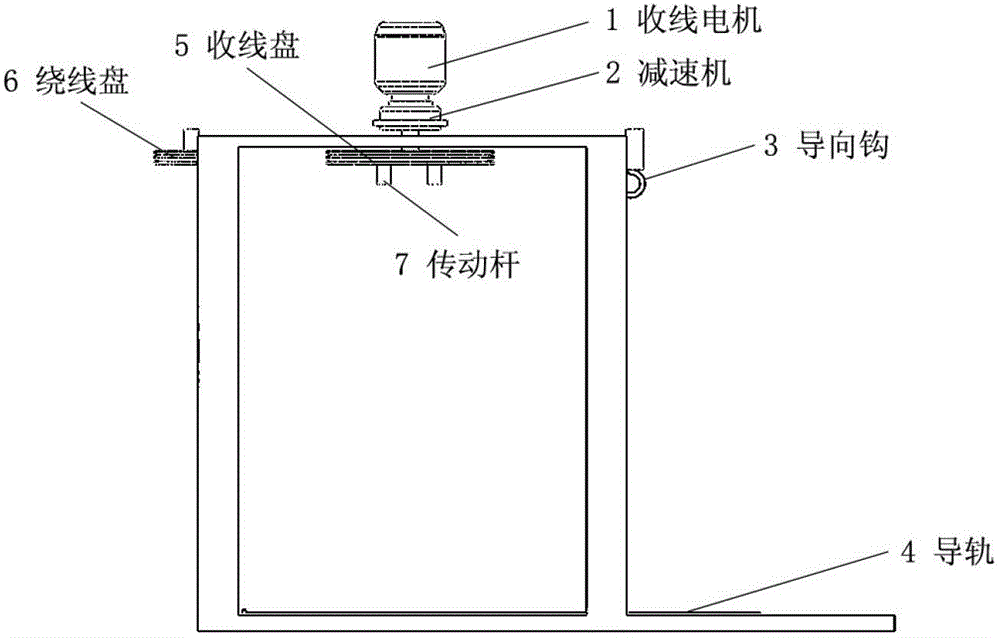

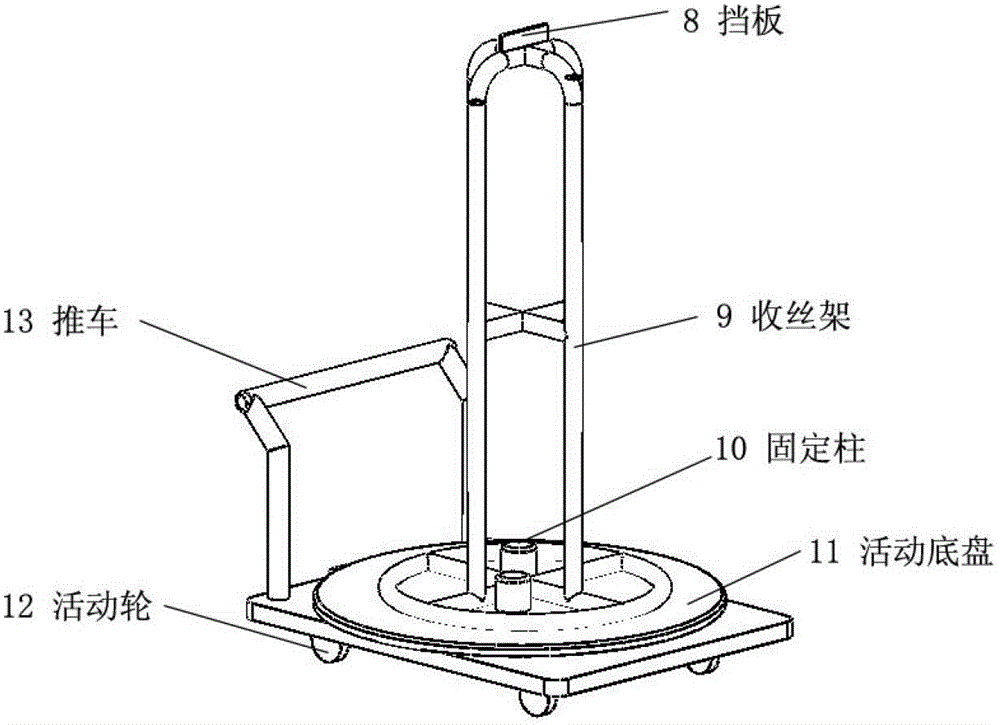

[0029] Such as Figure 1-Figure 3 As shown, after the steel wire enters the take-up device, it first enters the winding reel 6 and the take-up reel 5, and through the guide hook 3, the steel wire is taken up on the take-up frame 9. The winding reel 6 and the take-up reel 5 adopt double-layer V-groove design, and the steel wire is wound twice on the winding reel 6 and the take-up reel 5, so as to ensure sufficient friction between the steel wire and the take-up reel 5, and increase the resistance to the steel wire. traction and prevent slipping. The traction of this device is that the top is a take-up motor 1, which adopts a 2.2KW torque three-phase asynchronous motor, and the take-up motor 1 transmits power to the reducer 2 to obtain a larger torque. Then by driving the transmission rod 7 on the wire take-up reel 5, the transmission rod 7 is rotated after contacting the baffle plate 8 on the wire collection frame 9, and the wire collection frame 9 conflicts with the fixed col...

example 2

[0031] On the basis of the above examples, if Figure 1 to Figure 3 As shown, during the operation of the steel wire, as the number of steel wires on the wire receiving frame 9 increases, the output speed of the wire receiving motor 1 will gradually decrease. By adopting the AC frequency conversion speed regulation technology, the speed of the steel wire in the heat treatment process is guaranteed to be moderate, preventing the steel wire from Uneven wire cleaner performance due to speed fluctuations.

example 3

[0033] On the basis of the above examples, if Figure 1 to Figure 3 As shown, during the wire take-up process, the steel wire automatically falls onto the wire take-up frame 9 by its own weight. When the steel wire reaches the required weight, the lower movable wheel 12 is driven by pulling the cart 13, and the cart 13 is pulled out of the wire take-up device. , then the steel wire is hung out together with the wire receiving rack 9, and then other empty wire receiving racks 9 are placed on the movable chassis 11, and by pushing the trolley 13, the movable wheel 12 below it enters the wire receiving device along the guide rail 4, that is, Continuous heat treatment of steel wire can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com