Electromagnetic induction quick water heating device

A rapid heating, electromagnetic induction technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of small correlation between insulator thickness and heating efficiency, difficult to control, tubular insulator damage, etc. Direct or indirect induction leakage problem, sensitive and accurate protection device, reducing the effect of possible damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

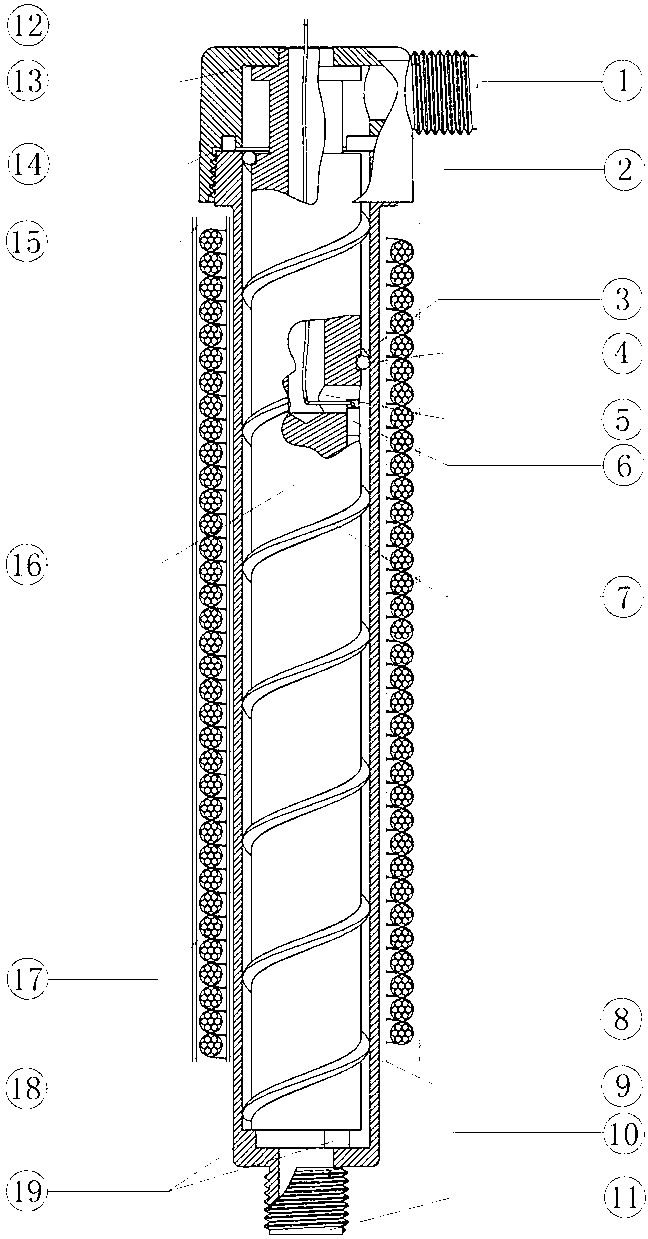

[0010] As shown in the figure: a heating element material rod 16 is set in the center of the water heating device, a blind hole is drilled in the center of the upper half of the heating element material rod 16, and a small hole connecting the blind hole is drilled at the bottom of the blind hole along the radial direction and a small platform is milled , forming a thermal circuit protector mounting hole 5, a thermal circuit protector 6 is installed in the thermal circuit protector mounting hole 5, the lead wire 12 of the thermal circuit protector 6 is drawn out through the thermal circuit protector mounting hole 5, and is sealed with a gasket 13 The installation hole 5 of the thermal circuit protector is sealed, and a spiral groove 3 similar to a lead screw is made on the heating body material rod 16 with a rotary milling lathe. The pitch should be slightly larger to facilitate the passage of water. A spiral support 7 made of thin rods, the material of the spiral support 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com