Monitoring method for mechanical deformation of mine filling body

A technology of force deformation and mine filling, applied in the direction of mechanical solid deformation measurement, measuring device, surveying and navigation, etc., can solve the problems of difficulty, no filling equipment, no monitoring of vertical deformation of filling body, etc., and achieve impact Small size, simple and accurate measurement method, small engineering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

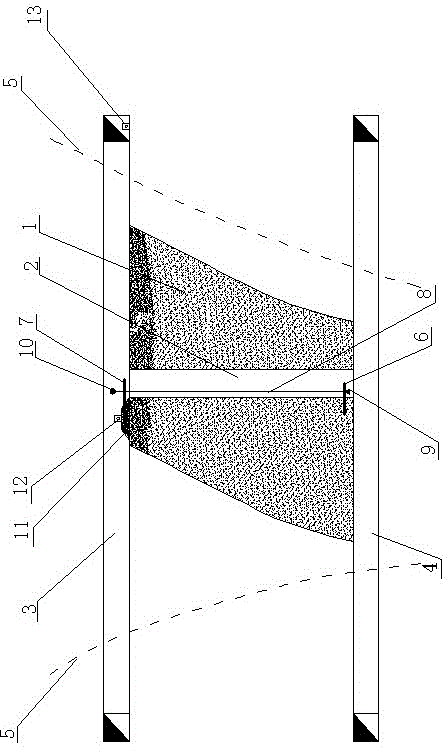

[0018] Such as figure 1 and 2 As shown, the filling body 1 is located between the upper segmental return airway 3 and the lower segmental return airway 4 of the mine, and the return air shaft 2 runs through the filling body 1 and connects with the upper segmental return airway 3 and the lower segmental return airway 4 phases are connected.

[0019] A method for monitoring deformation of a mine filling body under stress of the present invention comprises the following steps:

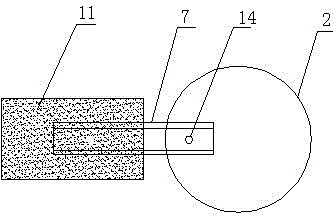

[0020] (1) A bolt 6 is fixed at the bottom of the filling body 1 corresponding to the return air shaft 2, and a channel steel 7 with holes is fixed at the wellhead of the return air shaft 2 at the top of the filling body 1 with concrete 11;

[0021] (2) Take a steel wire rope, one end of the steel wire rope 8 is fixed on the anchor rod 6 to form a fixed end 9, and the other end passes through the small hole 14 on the channel steel 7 to form a movable end 10, and the steel wire rope 8 is connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com