Intelligent detection method for vibration effective depth

An intelligent detection and in-depth technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as strong randomness, impossibility, and no accurate and effective technical solutions, so as to achieve intelligent vibration monitoring process, simple implementation method, The effect of high data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

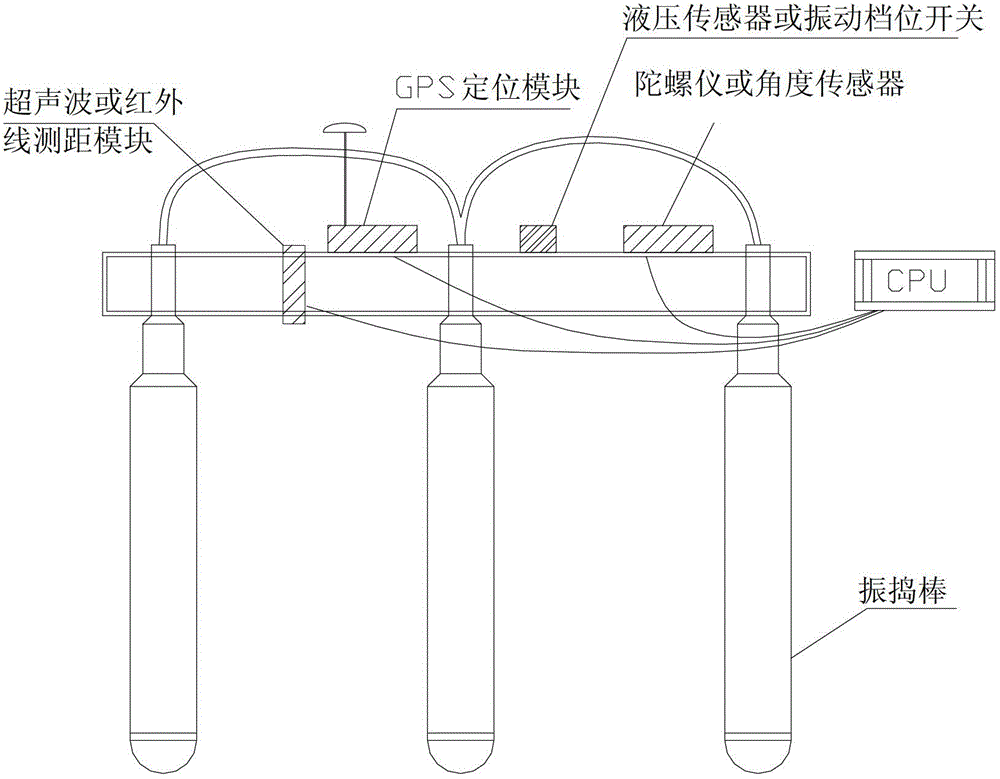

[0022] Such as figure 1 Shown is a structural schematic diagram of a vibrating rod adopting the technical solution of the present invention. The vibrator in this example mainly uses relevant hardware equipment for intelligent monitoring of concrete vibration quality, including GPS (Beidou) positioning module, hydraulic sensor (gear switch) and ultrasonic ranging module (infrared ranging module)) to collect relevant data , and then process the data through the CPU. Its specific working principle is as follows:

[0023] First, the coordinates (x, y) of the vibrator / rod are obtained in real time through the GPS (Beidou) module of the concrete vibrating quality intelligent monitor, which is used to judge the current vibrating position.

[0024] Then use the hydraulic sensor module of the concrete vibrating quality intelligent monitor to collect hydraulic data, and comprehensively judge the start and stop status (S) of the vibrator / rod through the change of the main pressure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com