Camera model standardization method and standardization device

A calibration device and a calibration method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of limiting the further improvement of accuracy and adaptability, difficulty in meeting the higher needs of industrial sites, and generalization of imaging errors, so as to improve the difficulty of calibration and realize High-precision visual measurement, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

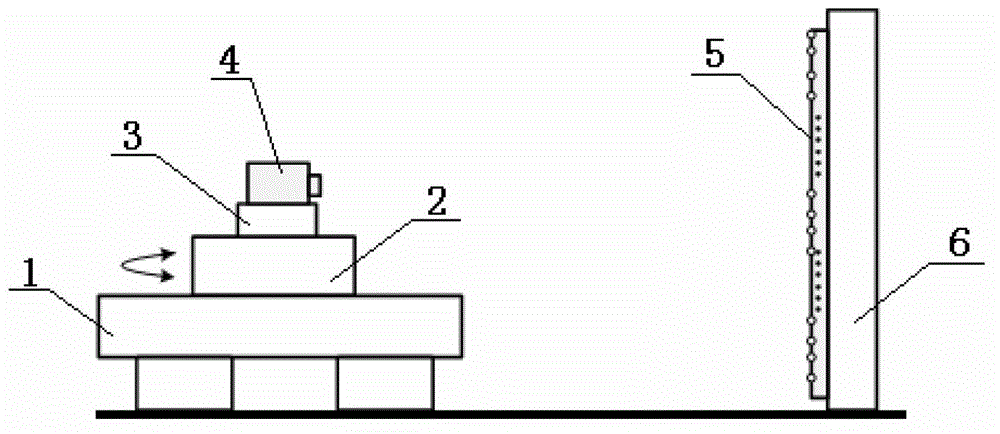

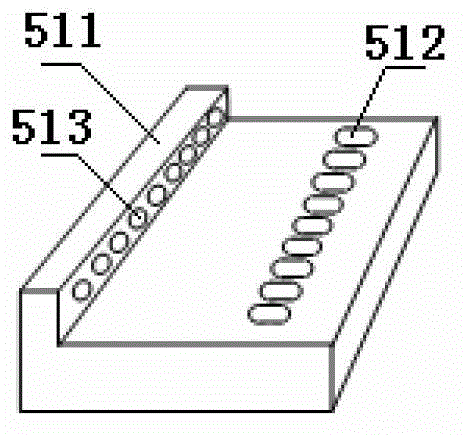

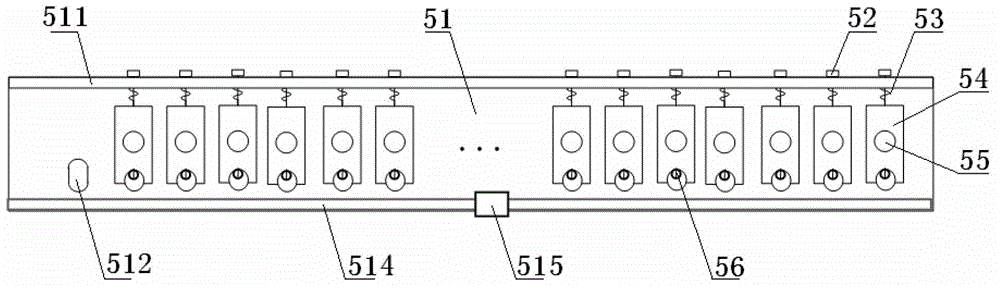

[0056] Such as figure 1 As shown, the camera model calibration device of this embodiment is composed of an optical platform 1 , a program-controlled multi-tooth indexing table 2 , a six-dimensional turntable 3 and a one-dimensional target 5 , and the one-dimensional target 5 is usually fixed on a bracket 6 .

[0057] A program-controlled multi-tooth indexing table 2 is placed on the optical table 1, a six-dimensional turntable 3 is placed on the program-controlled multi-tooth indexing table 2, and the six-dimensional turntable 3 is used to place the camera 4 to be calibrated.

[0058] The optical center of the camera 4 needs to coincide with the rotating shaft of the program-controlled multi-tooth indexing table 2 . The imaging plane of the camera 4 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com