Static electricity atomizing charge-to-mass ratio measuring device

A measuring device, electrostatic spray technology, applied in the direction of measuring device, measuring electrical variables, instruments, etc., to achieve the effect of reducing charge error and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

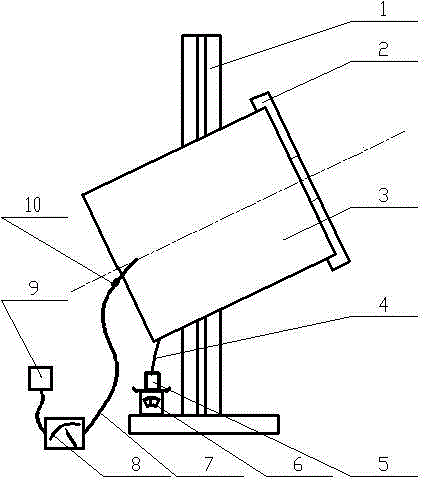

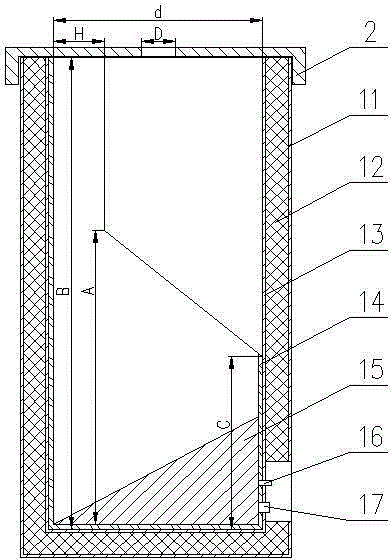

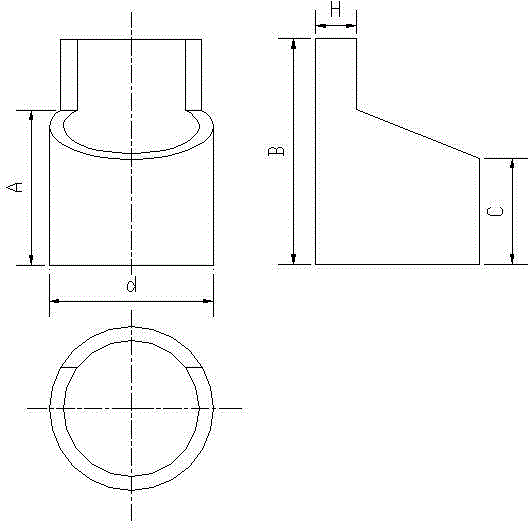

[0023] The schematic diagram of the device structure of the present invention is as figure 1 As shown, it is mainly composed of a droplet collection device, a droplet weighing device, a droplet power measurement device, and a data acquisition and processing system. Wherein the droplet carrying device is a liquid collection cylinder 3; the droplet weighing device is a precision electronic balance 6; the droplet power measuring device is a Model 6485 picoammeter 8; the data acquisition and processing system is a PC 9, and the data acquisition software Excelinx and Charge-to-mass ratio analysis software.

[0024] combine figure 1 , when implementing the present invention, according to figure 1 Connect the liquid collection cylinder 3 and the Modle6485 picoammeter 8: connect one end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope angle | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com