Detection method for current converter trigger control device function

A technology of triggering control and detection method, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the gaps in the inability to obtain test data, the inability to verify the function of valve-based electronic equipment, the coordination of control and protection equipment, and the verification of reliability functions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

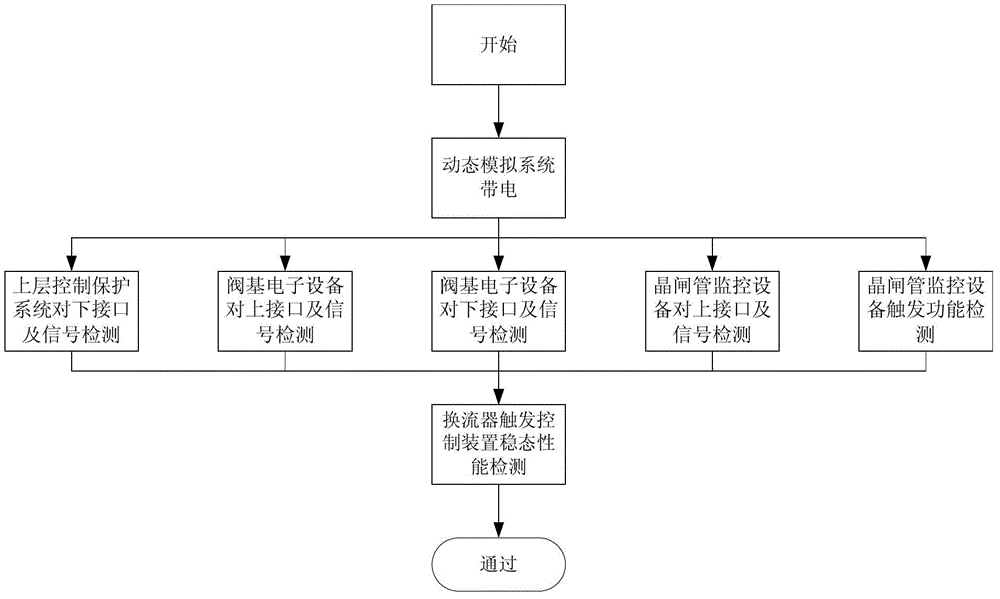

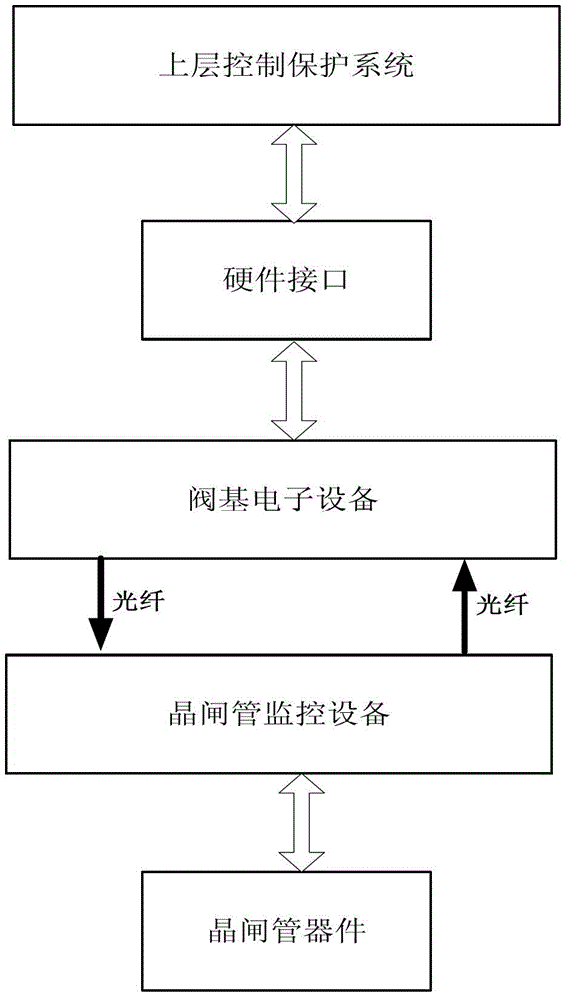

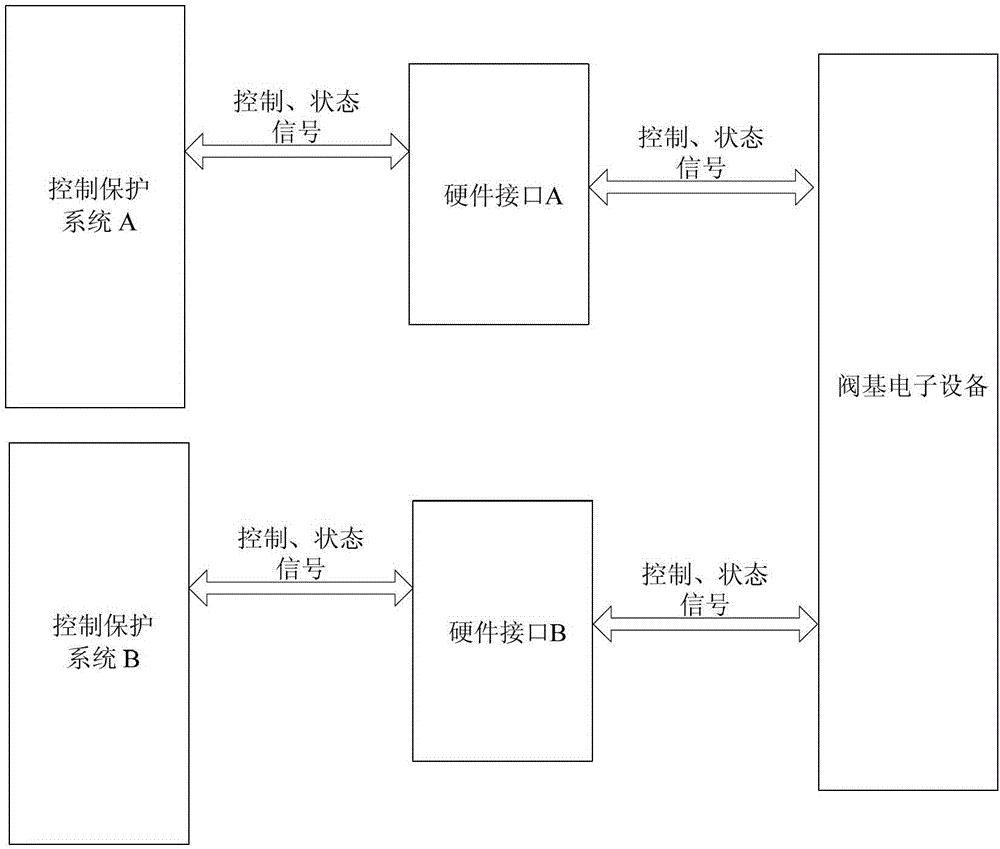

[0032] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The invention provides a method for detecting the function of a converter trigger control device. Firstly, it is necessary to establish a dynamic simulation test system integrating primary and secondary. Thyristor equipment, thyristor monitoring equipment, voltage regulators, voltage acquisition devices, power load equipment, and physical connection cables between the equipment in each link. The physical connection cables mainly include cables and optical cables; the test system circuit is as follows: Figure 4 As shown, the primary side of the voltage regulating device is connected to the power supply by a cable, and the secondary side is connected to the three-phase input terminal of the thyristor device of the converter valve by a cable; the output terminal of the thyristor device of the converter valve is connected to the power lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com