Failure detector of 2M head and connected cable

A detector and fault technology, applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems such as complicated methods and long processing time, and achieve the effects of reducing workload, improving equipment operation rate, and shortening fault processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

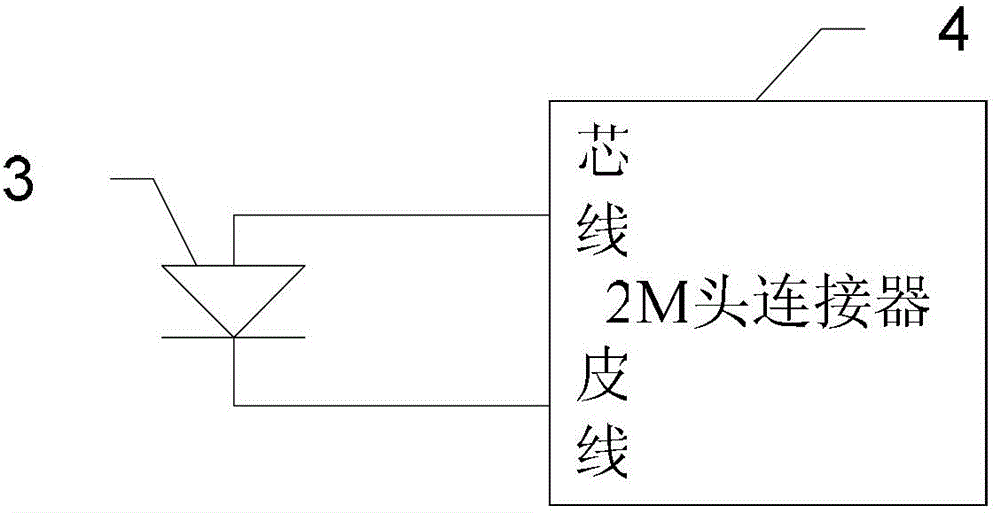

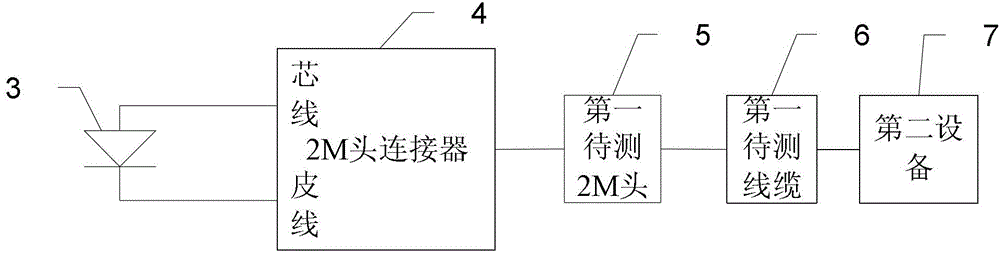

[0013] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, the 2M head described in this embodiment and the fault detector of the connected cable,

[0014] It includes 2M head connector 4 and LED 3;

[0015] The core wire at one end of the 2M head connector 4 is connected to the anode of the light emitting diode, and the leather wire at one end of the 2M head connector 4 is connected to the cathode of the light emitting diode 3 .

[0016] In actual use, one connection end of the 2M head connector 4 of this embodiment is used to connect one end of the first 2M head 5 to be tested, and the other end of the first 2M head 5 to be tested is passed through the first cable to be tested. 6 is connected with a second device 7 . In the case of the normal operation of the second device 7, if the light-emitting diode of the present invention is luminous, it proves that the first 2M head 5 to be tested and the connected first cable 6 to be tested ...

specific Embodiment approach 2

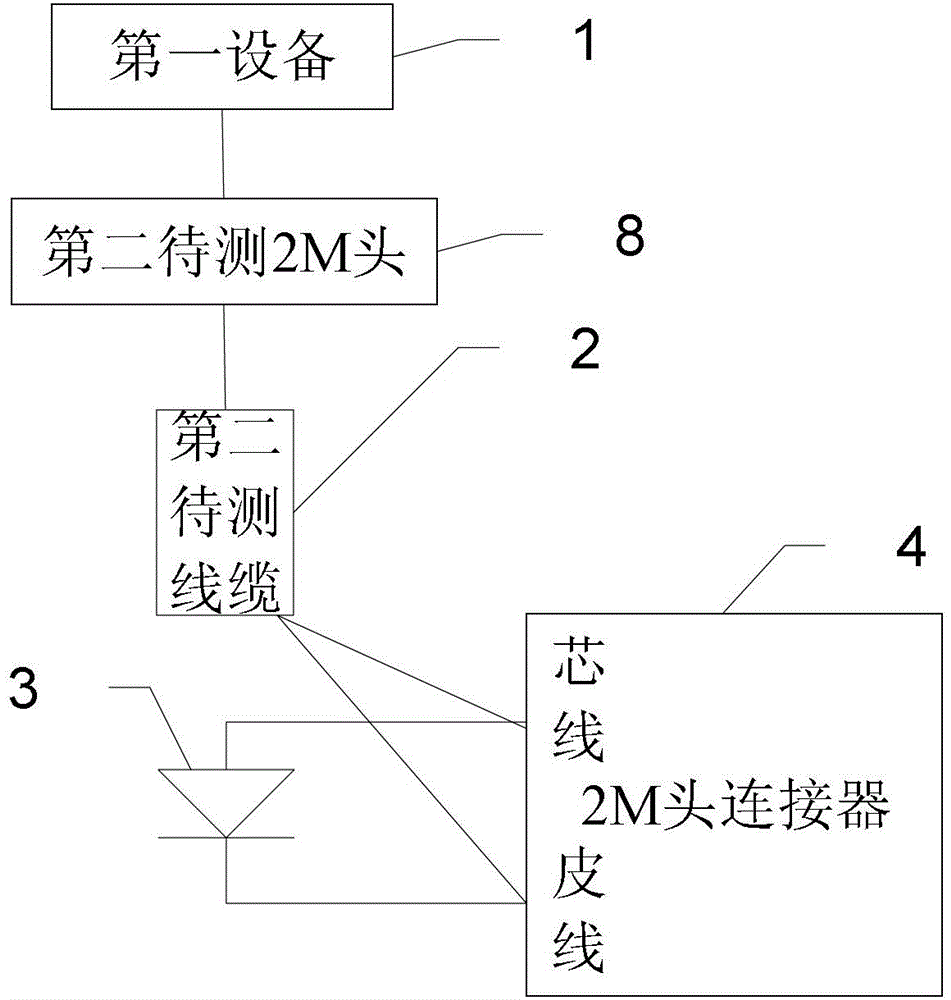

[0017] Specific implementation mode two: combination image 3 Describe this embodiment, this embodiment is a further limitation of the 2M head and the fault detector of the connected cable described in the second specific embodiment, and it also includes two audio cables;

[0018] One end of one audio line is connected to the anode of the light emitting diode 3 , and one end of the other audio line is connected to the cathode of the light emitting diode 3 .

[0019] In actual use, when the first device is connected to one end of the second cable 2 to be tested through the second 2M head 8 to be tested, and the other end of the second cable 2 to be tested does not have a 2M head, the measurement process is: a The other end of the audio cable is connected to the core wire at the other end of the second cable under test 2 , and the other end of the other audio cable is connected to the leather wire at the other end of the second cable under test 2 . When the second device 1 is w...

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is a further limitation of the 2M head and the fault detector of the connected cable described in Embodiment 1. The model of the 2M head connector 4 is: L9-J or L9-KY Or L9-KKY or L9-JN or L9-JKJ or CEN-75J.

[0021] This invention is easy to manufacture, simple and easy to implement, and has a very high utilization rate of front-line personnel in systems in the fields of communication, dispatching data network, centralized control video, telecontrol private network, power environment monitoring, etc.

[0022] In the case of determining that the 2M head and the cable of the connected device are faultless, the present invention can also be used to detect whether the sending device is operating normally. If the light-emitting diode is on, it proves that the sending device is normal. If the light-emitting diode is off, then Proof that the sending device is not functioning properly.

[0023] When it is determined that the cable under test or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com