Dry Microwave Capacitors

A technology for microwave ovens and capacitors, which is applied to capacitors, fixed capacitor terminals, and structurally fixed capacitor combinations, etc., can solve the problems of high temperature in the center of the capacitor, long wires, and complicated processes, and achieves difficult displacement, fast heat dissipation, and temperature rise. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

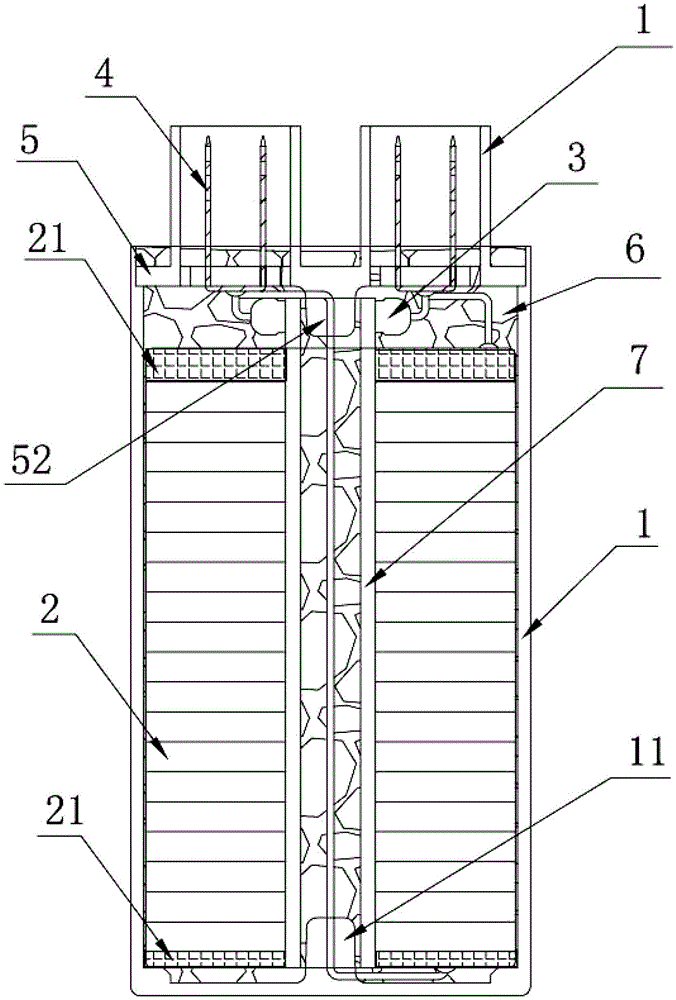

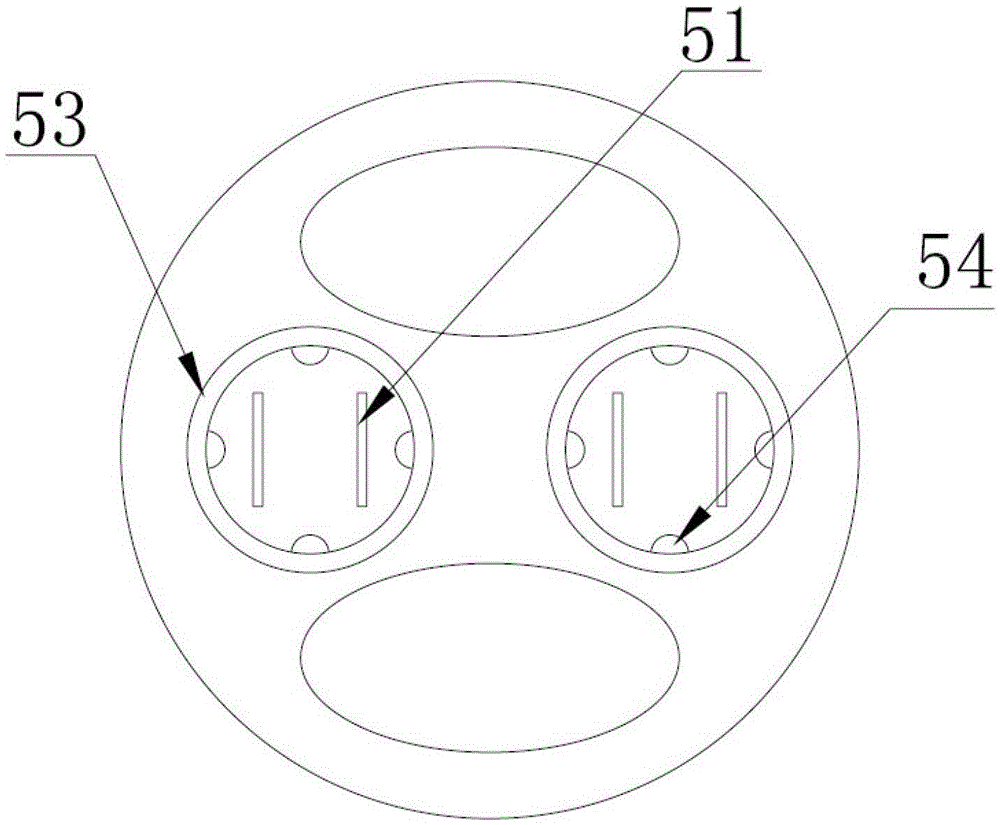

[0017] like figure 1 and figure 2 As shown, the dry-type microwave oven capacitor of the present invention includes a shell 1, a capacitor core 2, a discharge resistor 3, a flat quick-connect insert 4, an upper cover 5 and a potting compound 6, and the capacitor core 2 is made of metallized polymer The acrylic film is wound, the capacitor core 2 is provided with a hollow mandrel 7, the upper cover 5 is provided with a square hole 51, and the flat quick-connect insert 4 is inserted into the square hole 51, the The discharge resistor 3 is located between the upper cover 5 and the capacitor core 2, and the two ends of the discharge resistor 3 are respectively electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com