A dispensing method of heat dissipation cover adhesive

A distribution method and technology of heat dissipation cover, which are applied in the manufacture of devices, electrical components, semiconductor/solid-state devices, etc. which apply liquid to the surface, can solve the problems of high input cost and side glue overflow, reduce R&D costs, and achieve reliable adhesion. The effect of reducing the parameter adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

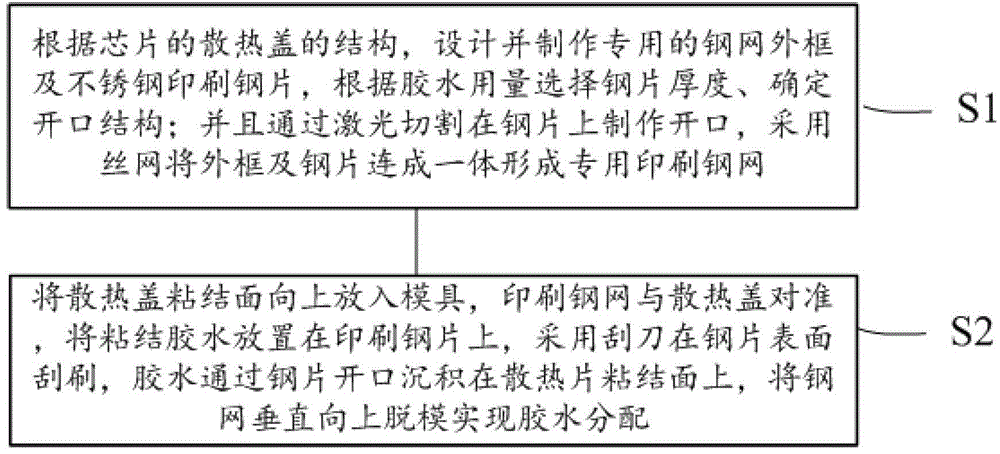

[0030] figure 1 A flow chart of a method for distributing adhesive for a heat dissipation cover according to an embodiment of the present invention is schematically shown.

[0031] Specifically, as figure 1 As shown, the dispensing method of the heat dissipation cover adhesive according to the embodiment of the present invention includes:

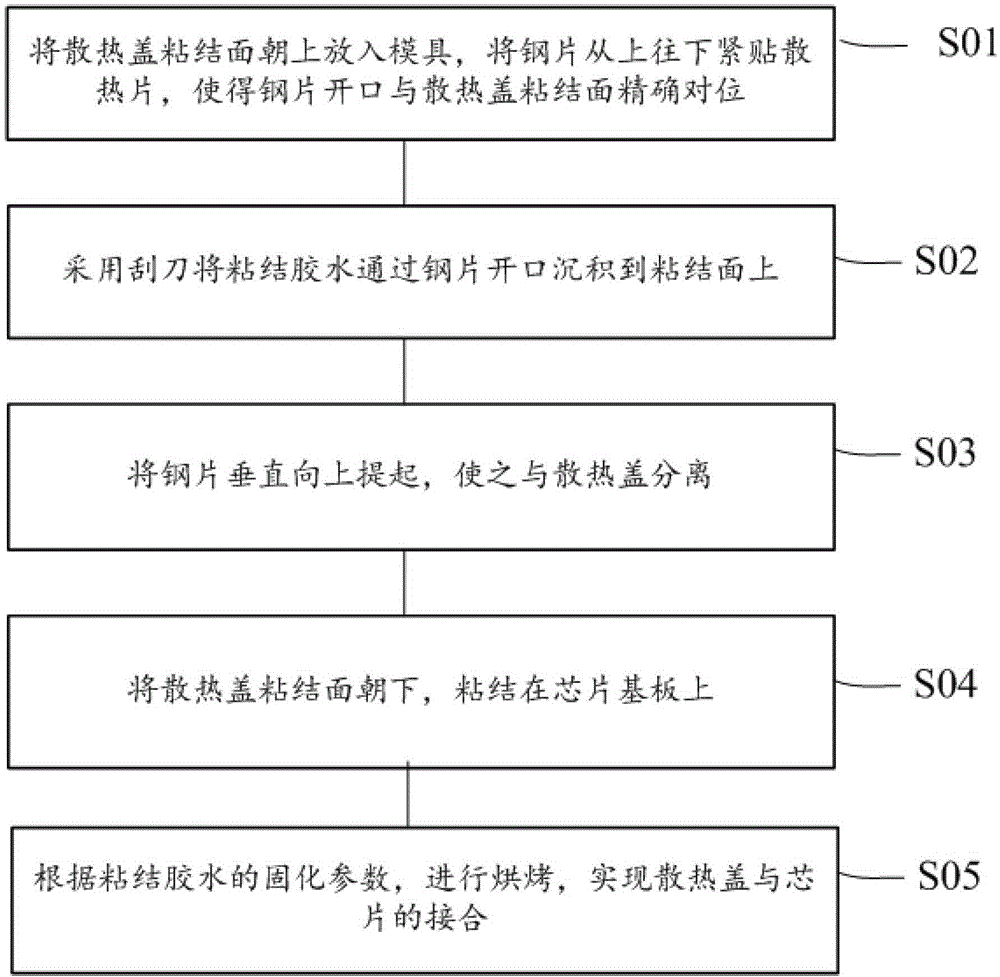

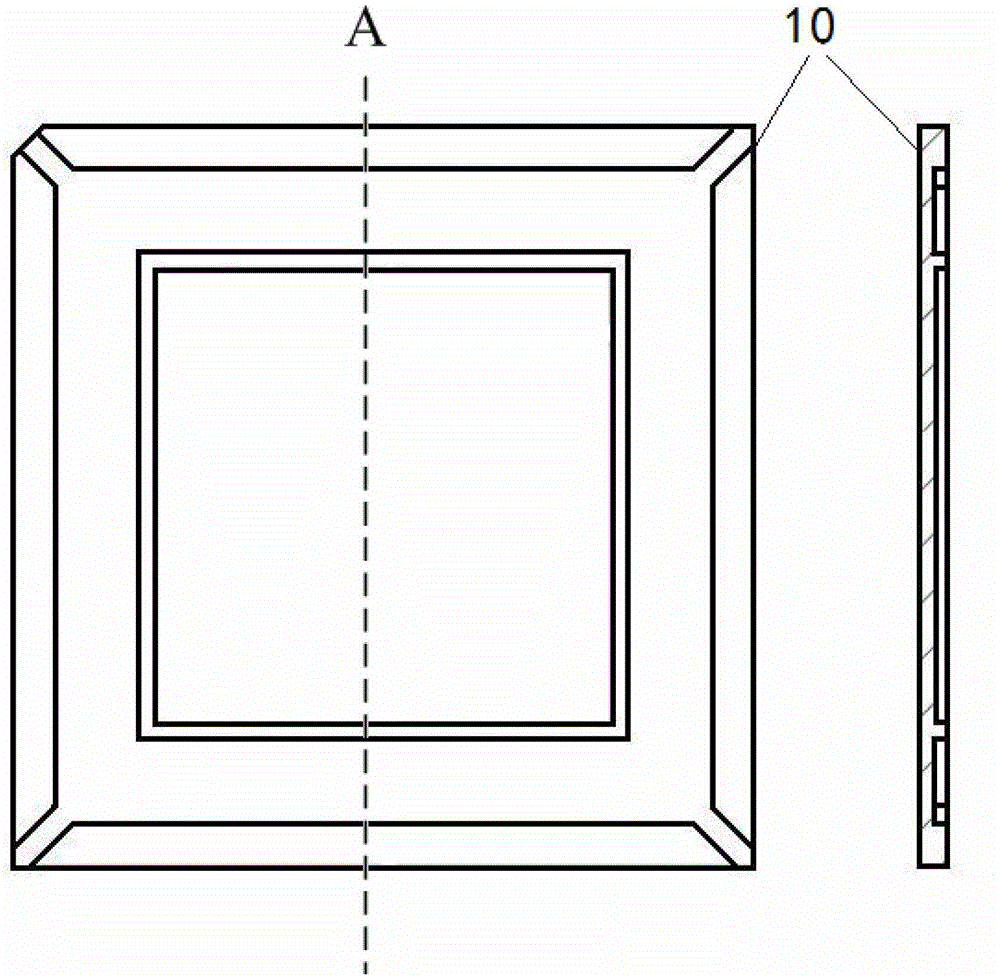

[0032] Stencil design and manufacture step S1: According to the cooling cover 10 of the chip (see image 3 ) structure, design and manufacture a special steel mesh frame and stainless steel printing steel sheet, select the thickness of the steel sheet according to the amount of glue, determine the opening structure; and make the opening 21 on the steel sheet by laser cutting (see Figure 4 ), using silk sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com