Wire protection film stripping device and wire protection film stripping device method

A technology of stripping device and protective film, which is applied in the direction of equipment for dismantling/armoring cables, etc., can solve the problem of inability to strip the protective film, and achieve the effect of easy and reliable stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

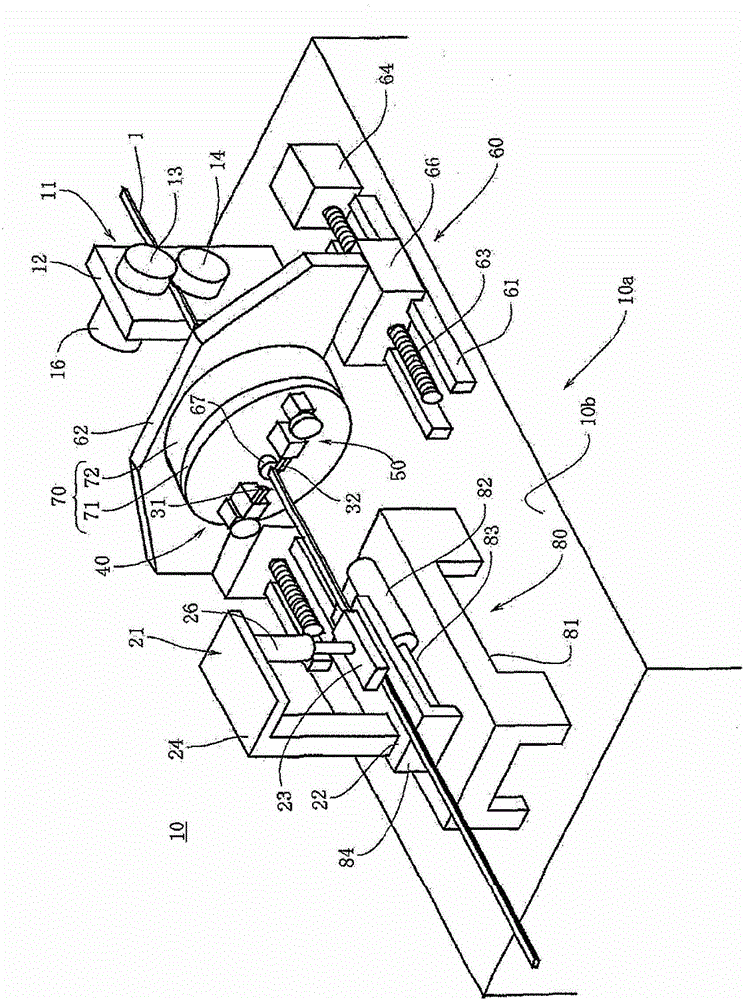

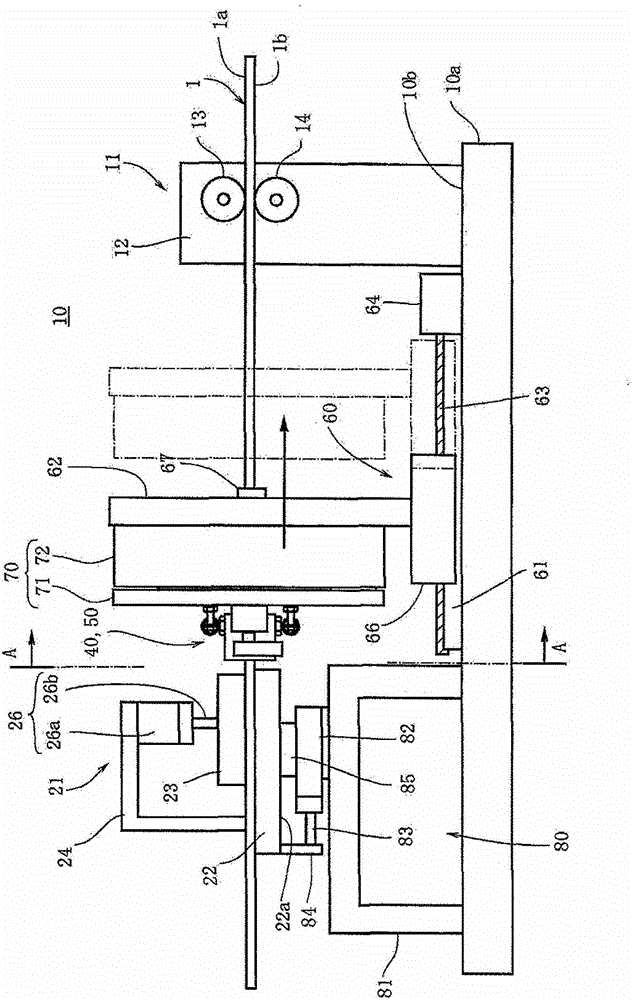

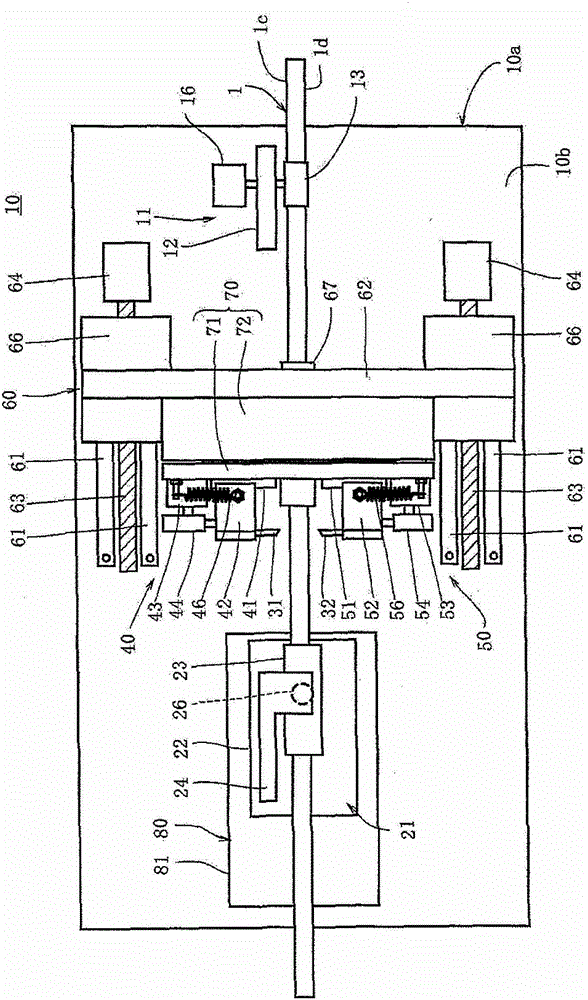

[0033] Next, the best mode for implementing the present invention will be described based on the drawings.

[0034] Figure 1~Figure 3 The protective film peeling apparatus 10 of the wire rod of this invention is shown. This protective film stripping device 10 is used to ensure electrical contact with the terminal around which the wire 1 is wound or to directly serve as an electrical contact part when the wire 1 covered with a protective film such as an insulating protective film is wound around a bobbin, a stator core, or the like. , and a device for partially peeling off the protective film of the wire 1 in advance. In this embodiment, the case where the protective film of the flat wire 1 having a rectangular cross-sectional shape is peeled off will be described as the type of wire rod. and if Figure 10 As shown, the configuration of the flat wire 1 includes: a conductor part 2 having a rectangular cross section; and a protective film 3 covering the periphery of the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com