Motor driving device without sensor, and back electromotive force detection circuit and detection method

一种反电动势、检测电路的技术,应用在电子换向电动机控制、单个电动机转速/转矩控制、电气元件等方向,能够解决成本增高、降低产品竞争力等问题,达到降低成本需求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

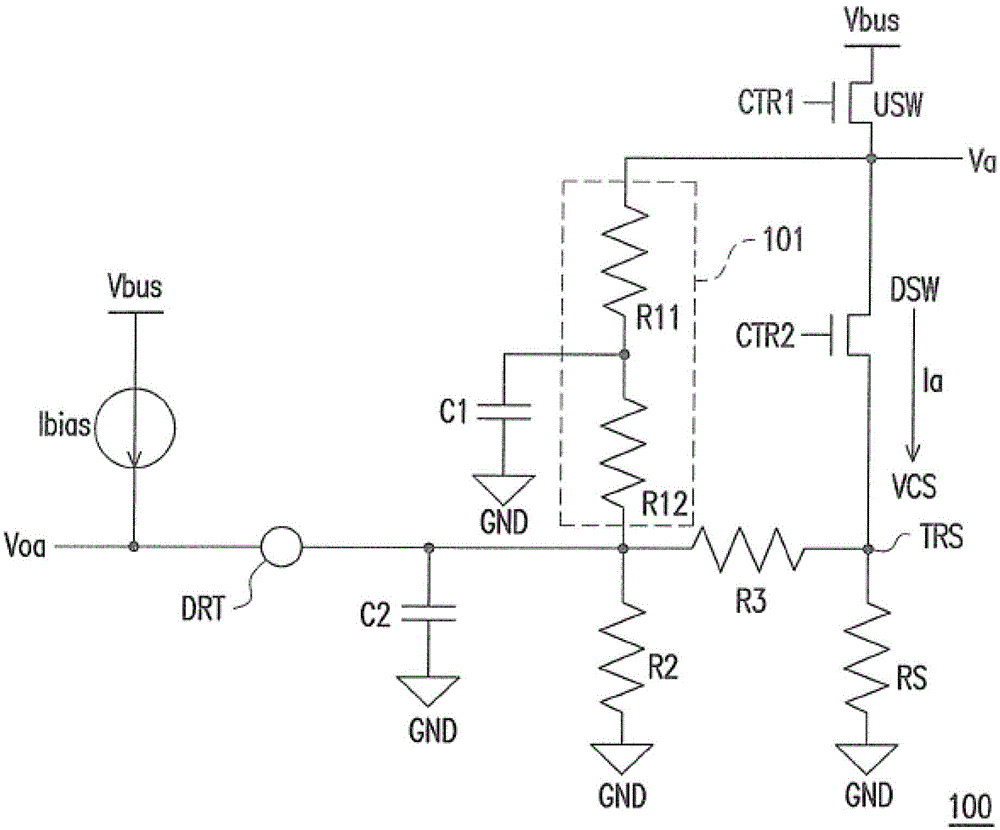

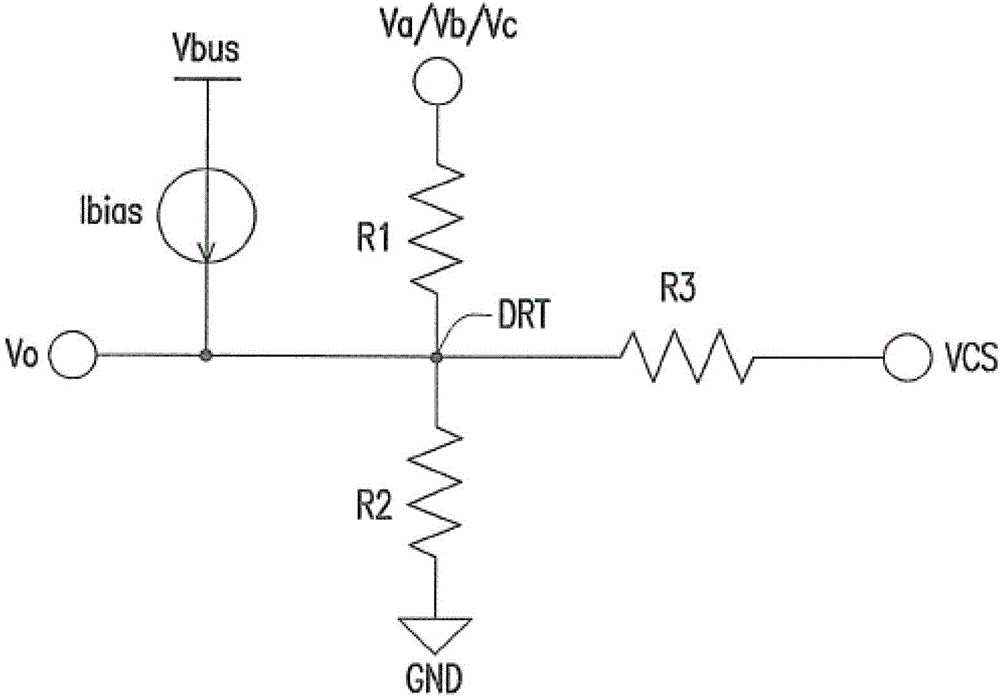

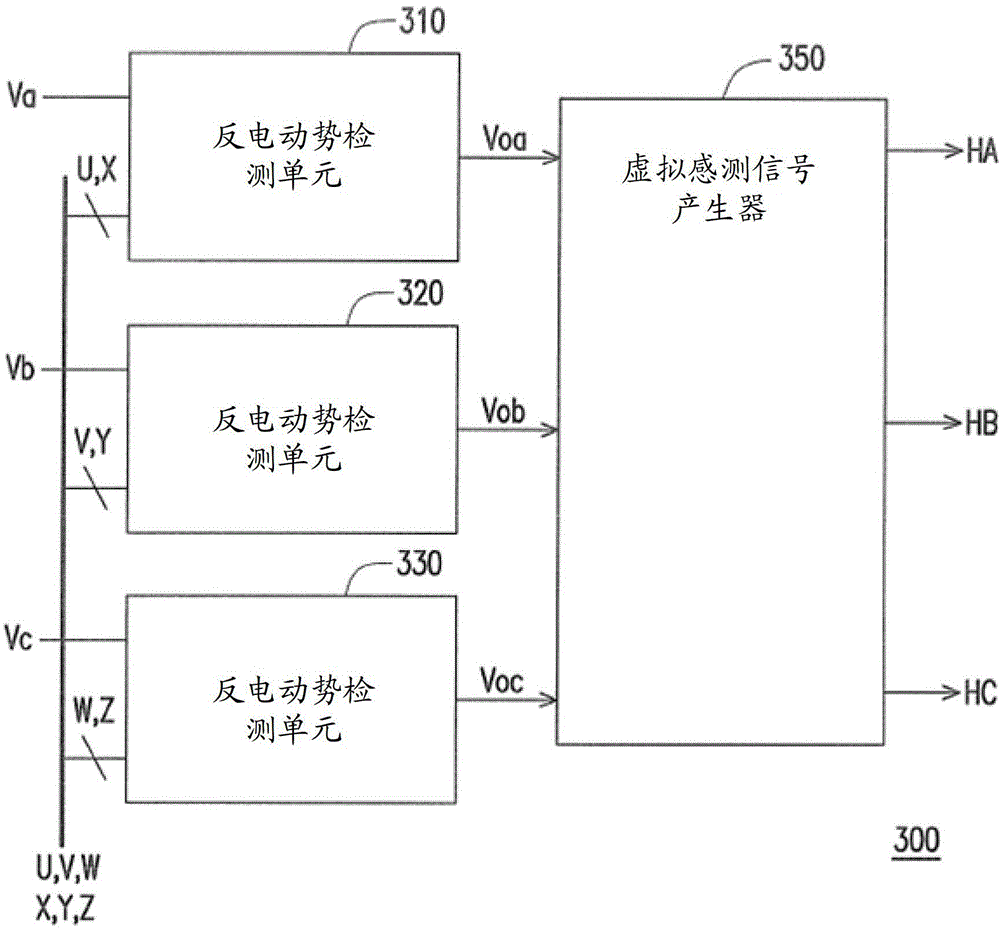

[0039] Please refer to figure 1 , figure 1 A schematic diagram of a back electromotive force detection circuit 100 of a motor according to an embodiment of the present invention is shown. The back EMF detection circuit 100 includes an upper switch USW, a lower switch DSW, a current detection resistor RS, an impedance generator 101, R2 and R3, a bias current source Ibias, and filter capacitors C1 and C2. The first end of the upper switch USW is coupled to the reference voltage source Vbus, and the second end thereof is coupled to the driving voltage Va, and is controlled by the control signal CTR1. The first terminal of the lower switch DSW is coupled to the second terminal of the upper switch USW, and the lower switch DSW is controlled by the control signal CTR2. The current detection resistor RS is connected in series between the second end of the lower switch DSW and the reference ground voltage GND. A first terminal of the impedance generator 101 is coupled to a second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com