Seat bracket assembly and sofa base adopting seat bracket assembly

A seat and assembly technology, applied in the field of furniture, can solve problems that affect product life and safety, product quality cannot be guaranteed, and wooden support surfaces are not strong, so as to save materials, increase pressure bearing capacity, and increase trust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following drawings and in conjunction with the embodiments further illustrate the present invention.

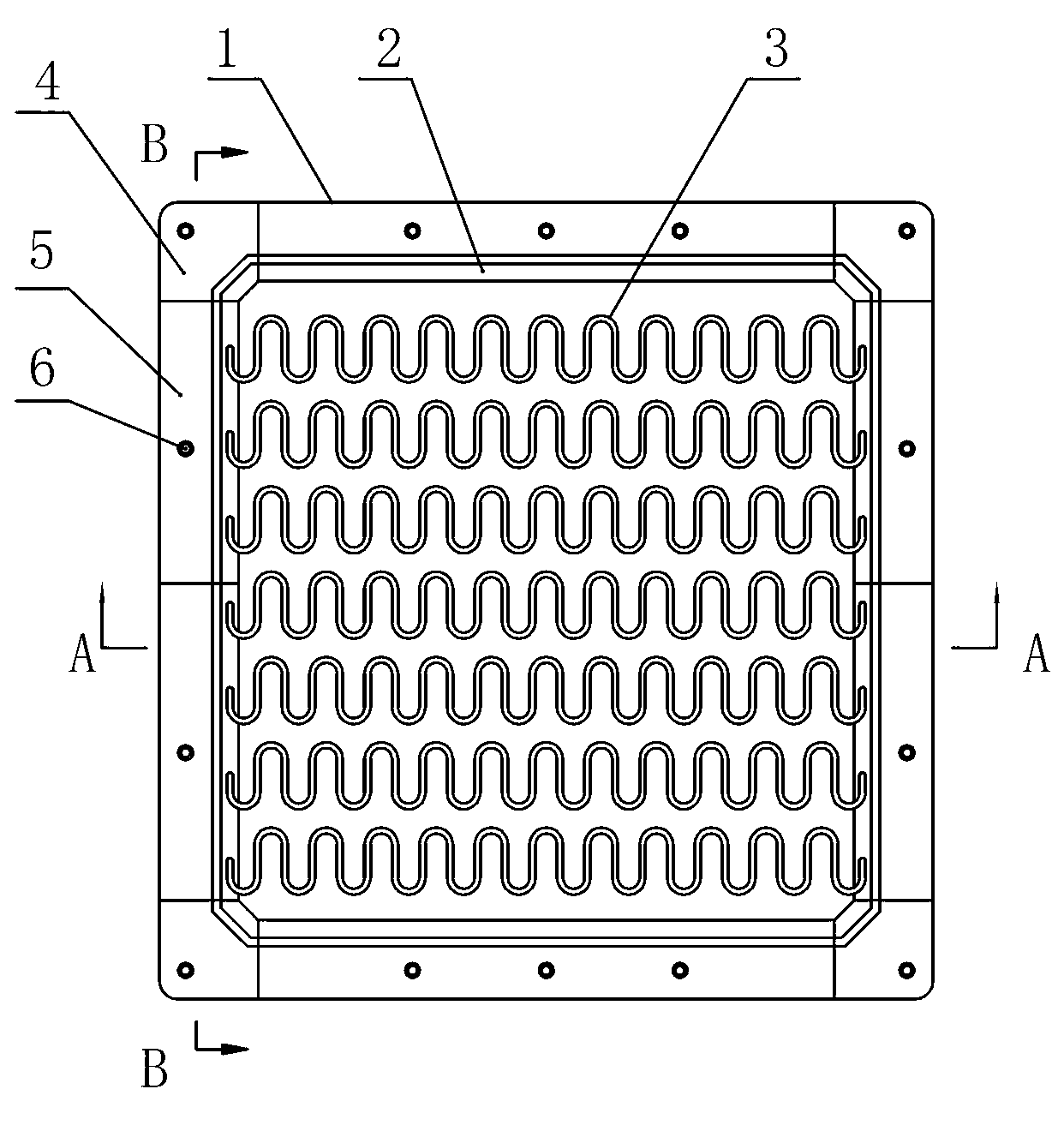

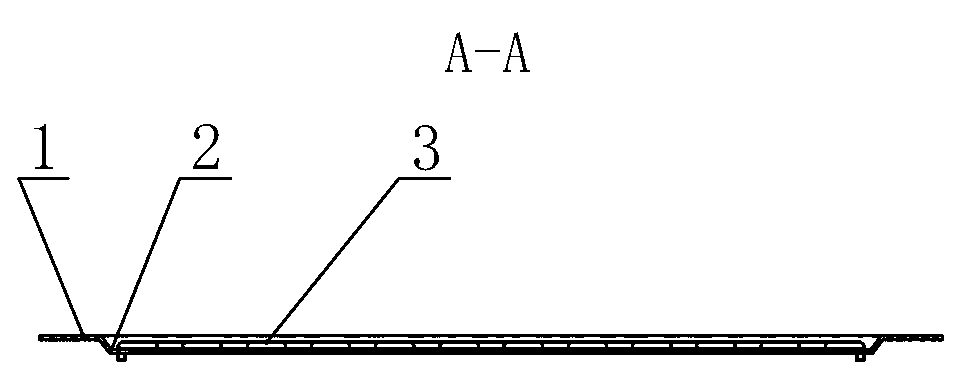

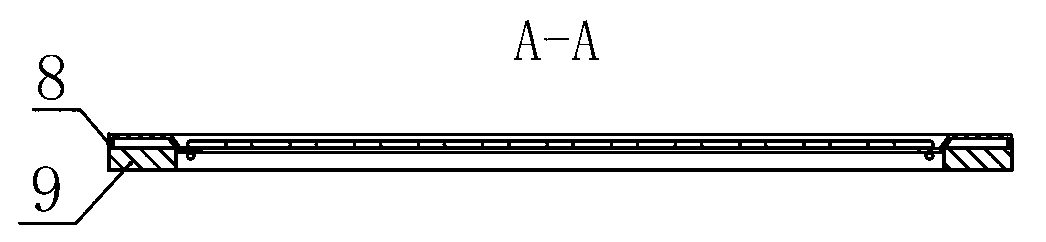

[0036] as attached figure 1 , figure 2 , Figure 4 As shown, a seat bracket assembly includes a metal frame 1, the inner edge of the metal frame 1 is concave to form a spring hanging frame 2, and multiple rows of flat serpentine springs 3 are horizontally fixed on the spring hanging frame 2 to form a snake shaped spring bearing surface, the metal frame 1 is enclosed and fixed by a plurality of modular corners 4 and a plurality of modular side bars 5, and the two sides of the modular corners 4 and modular side bars 5 There is a downward connecting bend 7, and the modular corner 4 and the modular side strip 5 are fixed together through the connecting bend 7, and the inner side of the modular corner 4 and the modular side strip 5 are made for Form the stepped shape of the spring hanging frame 2.

[0037] The spring hanging frame 2 has a hanging spring hole, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com