Bending device for large induction furnace wall and bending method

A technology of bending device and induction furnace, which is applied in the field of metal processing, can solve problems such as technical leakage, lack of large blanks, and large blanks that cannot achieve the desired effect, and achieve convenient adjustment, high precision, and simple equipment operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

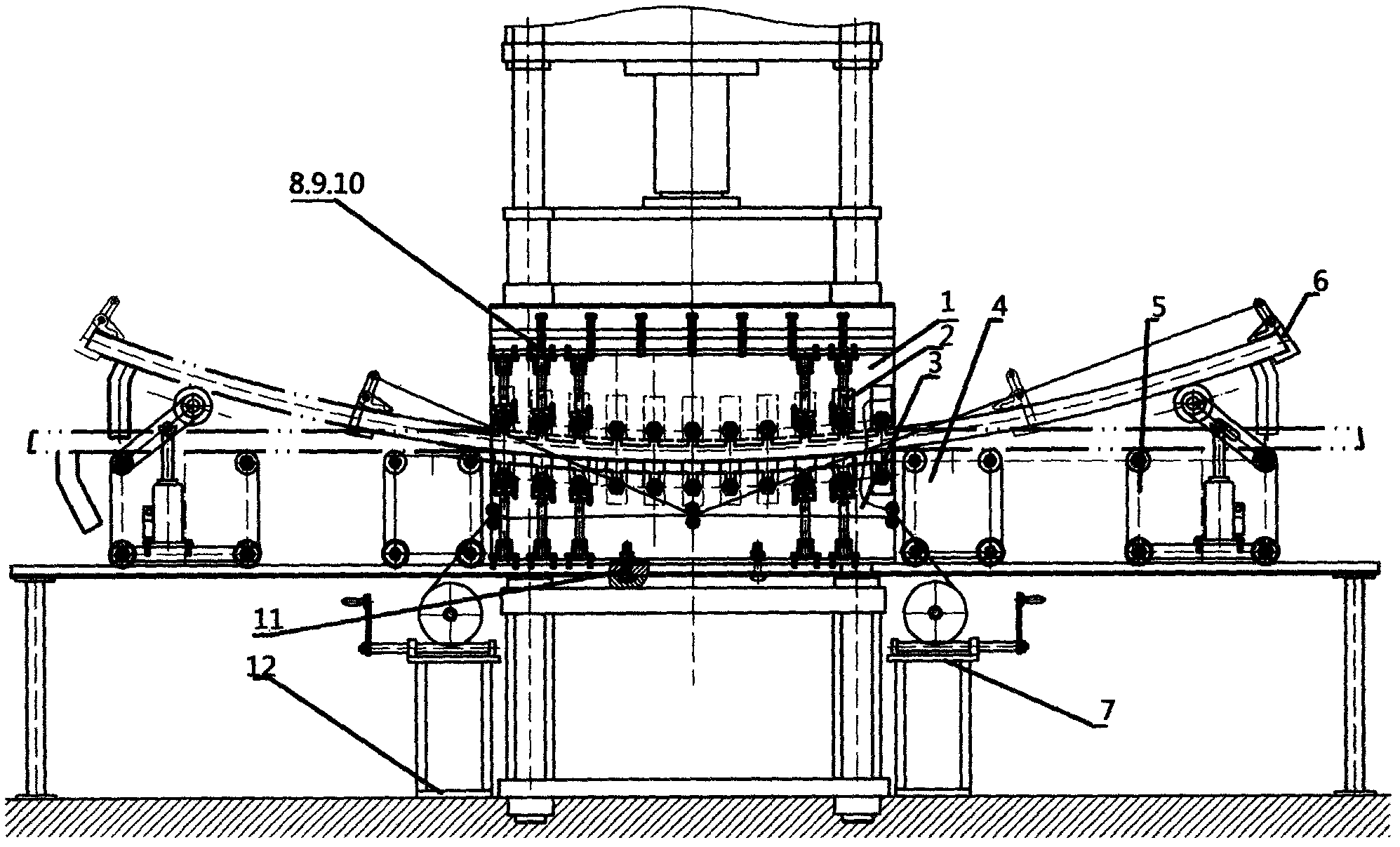

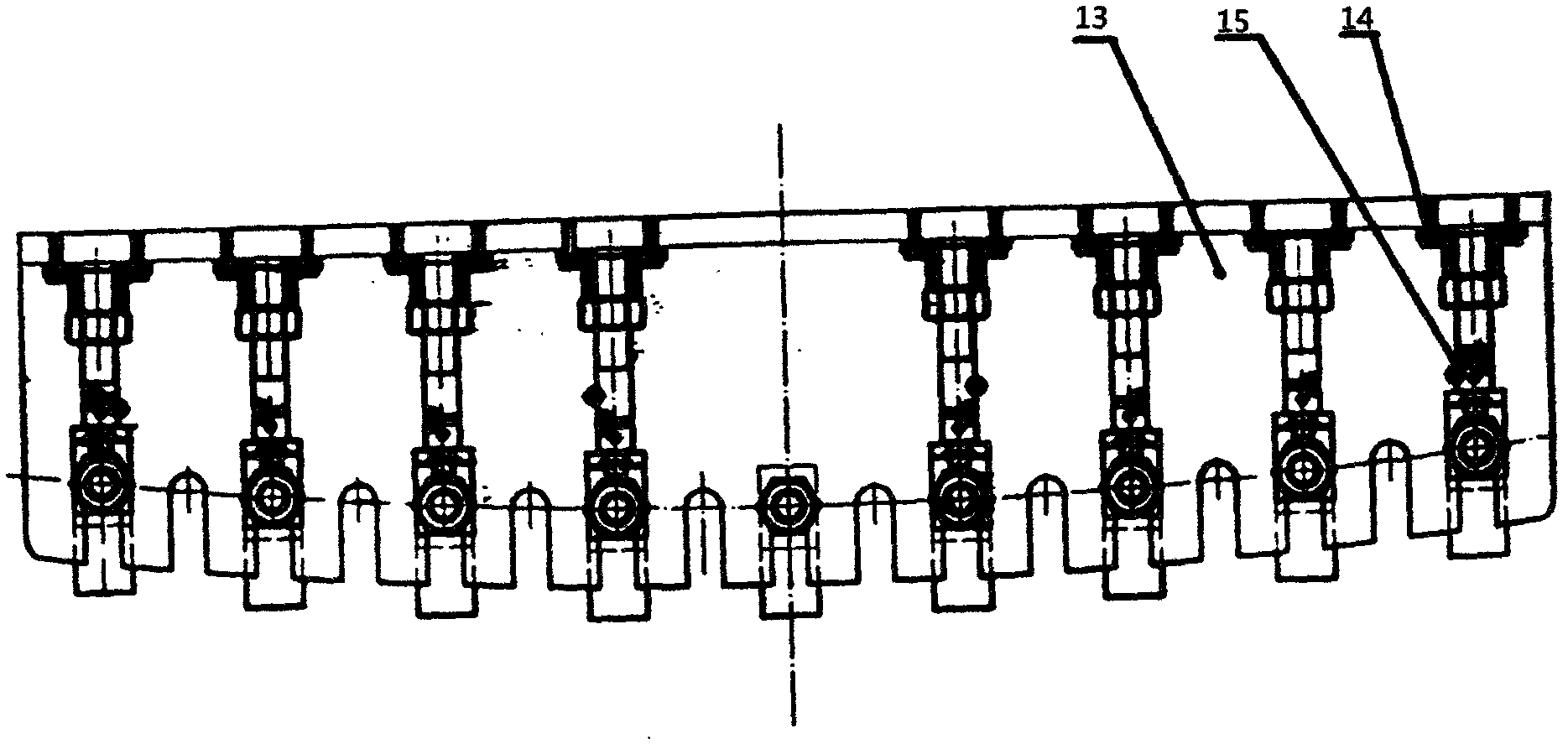

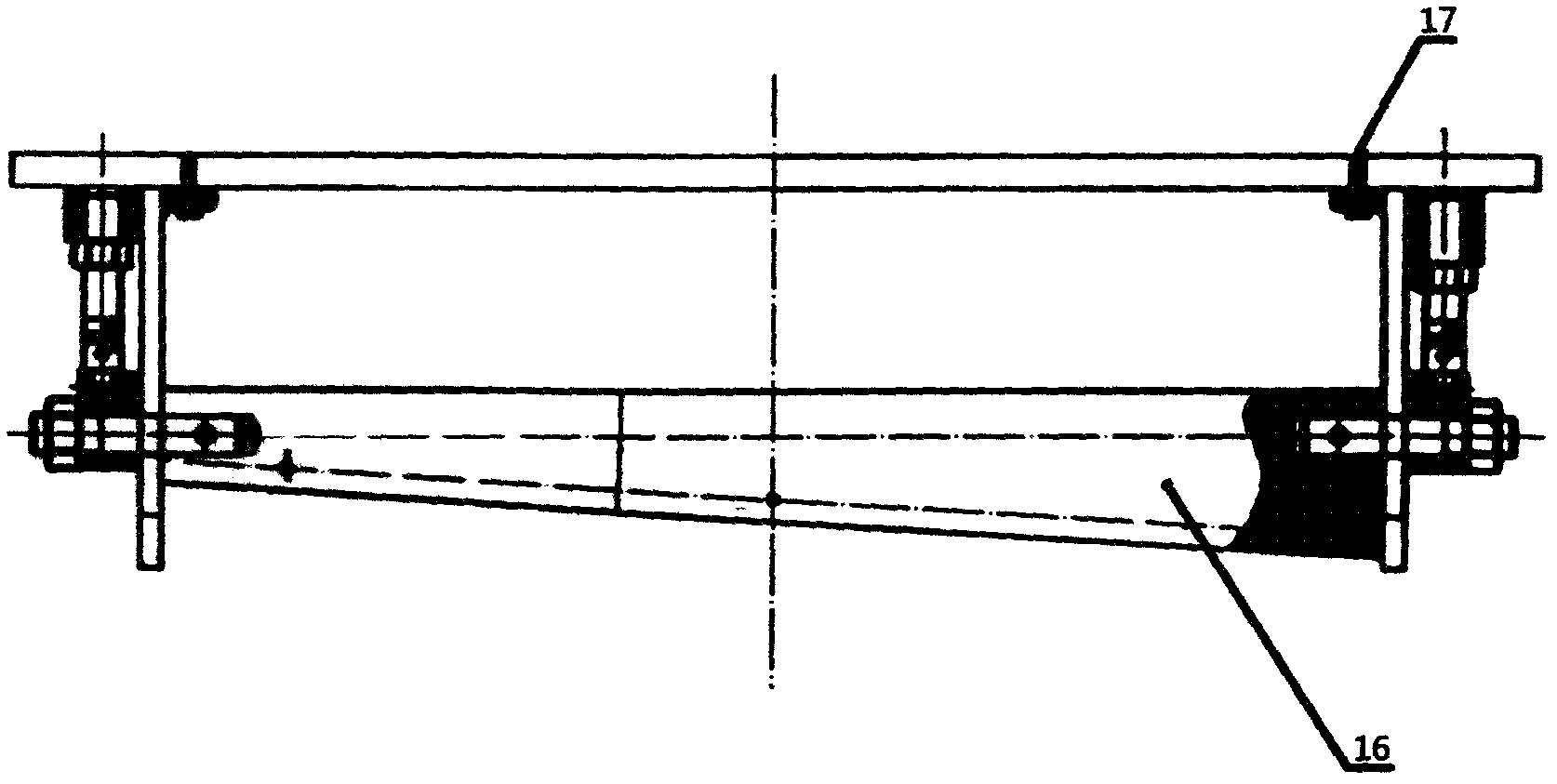

[0021] exist figure 1 In order to complete the pressing smoothly, first adjust the radian of the profiling. The radian of the profiling can be adjusted on the machine or off the machine. First, loosen the hexagonal nut (9). The height of the briquetting block is adjusted to both sides in turn, and the inclined material transport vehicle (4) carries out the support and transportation of the blank. When the blank lateral displacement and alignment are required after reaching the center, the hoist can be used to drive the movable support vehicle (5). To carry out the longitudinal displacement of the blank to the center, clamp and fix it with the clamp assembly (7). Especially when placing a long blank, use the winch assembly (7) to stir the reducer to pull the movable support vehicle (5) to move slowly. After moving to the desired position, the jacking device is put down. The bottom of the hoist is fixed with expansion bolts (12), and then the upper and lower forming components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com