Anti-vibration device

A technology of anti-vibration devices and cylindrical parts, which is applied in the direction of control devices, power devices, jet propulsion devices, etc., can solve problems such as restrictions, and achieve the effect of preventing relative displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

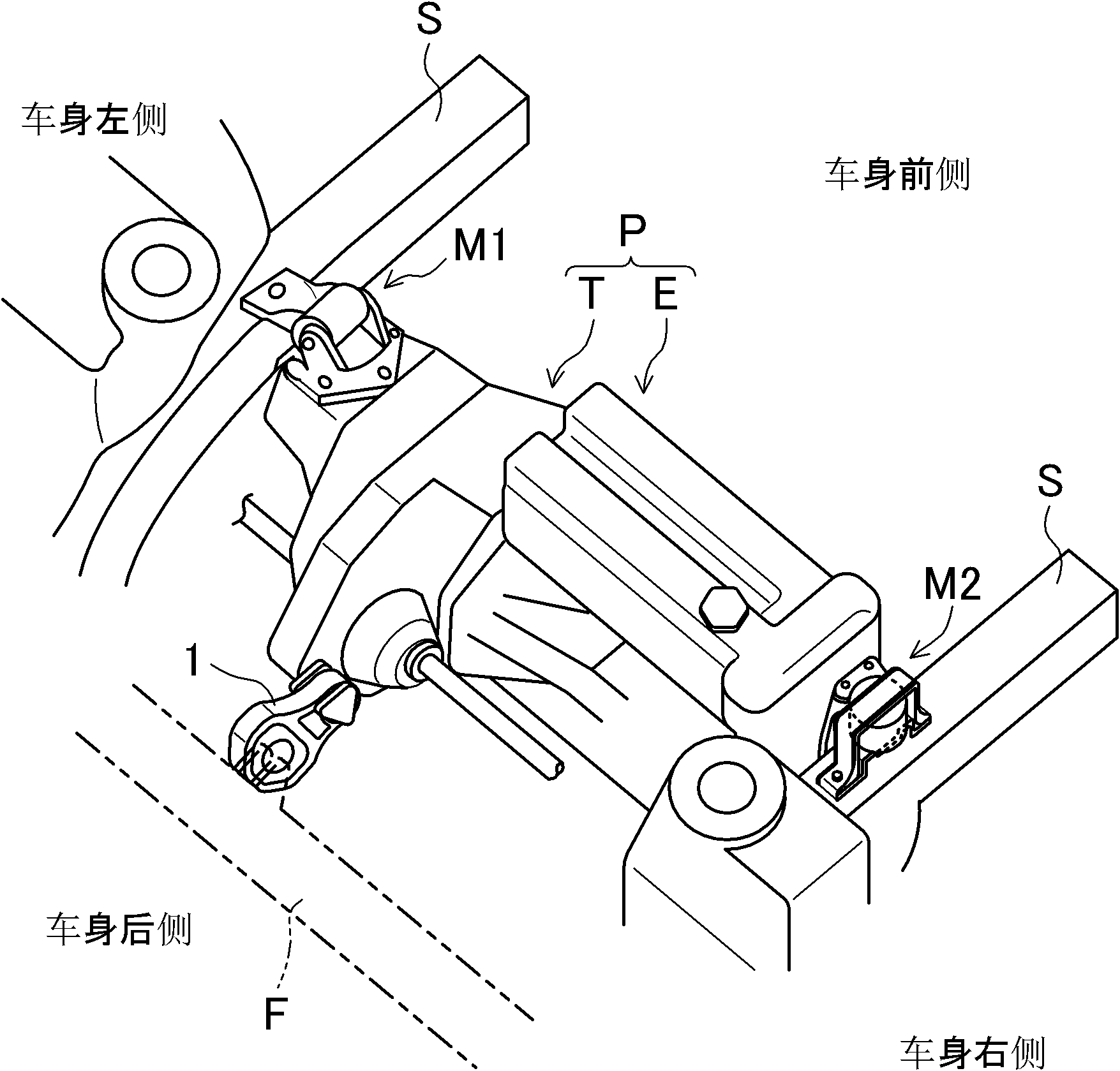

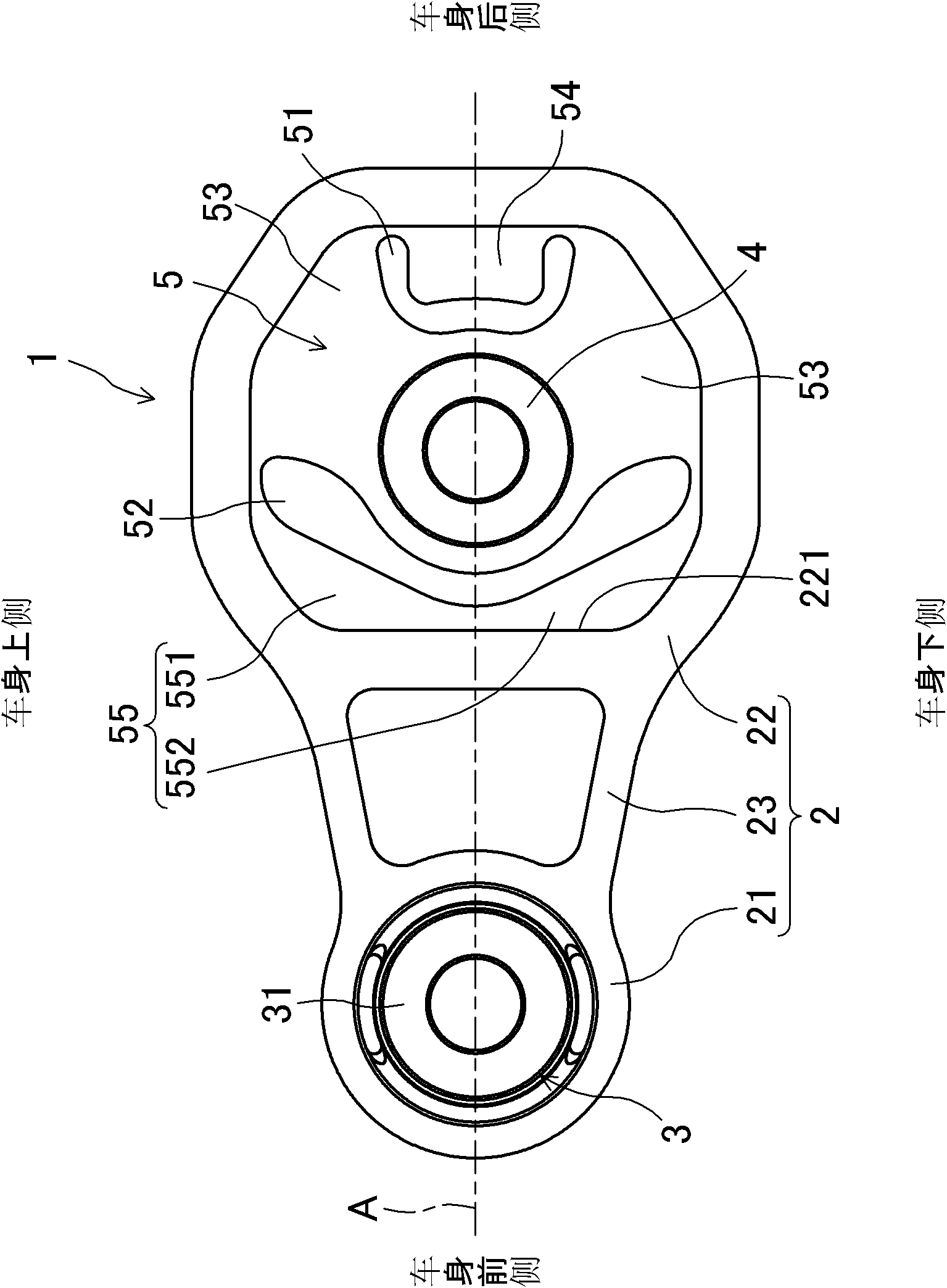

[0051] figure 1 It is a perspective view showing a schematic structure of the automobile engine mount system according to the embodiment. exist figure 1 Among them, the symbol P represents the engine-transmission assembly composed of the engine E and the transmission T in series.

[0052] The engine-transmission assembly P is arranged horizontally in the engine room such that the longitudinal direction of the engine-transmission assembly P coincides with the vehicle width direction. The engine-transmission assembly P is elastically supported with respect to the vehicle side member S by anti-vibration supports M1 and M2 respectively arranged at both ends in the longitudinal direction thereof. The two anti-vibration supports M1, M2 are arranged at positions higher than the main axis of inertia (roll axis) of the engine-transmission assembly P, so that the engine-transmission assembly P can be connected around the two anti-vibration supports. The swing support shafts of the lo...

no. 2 approach

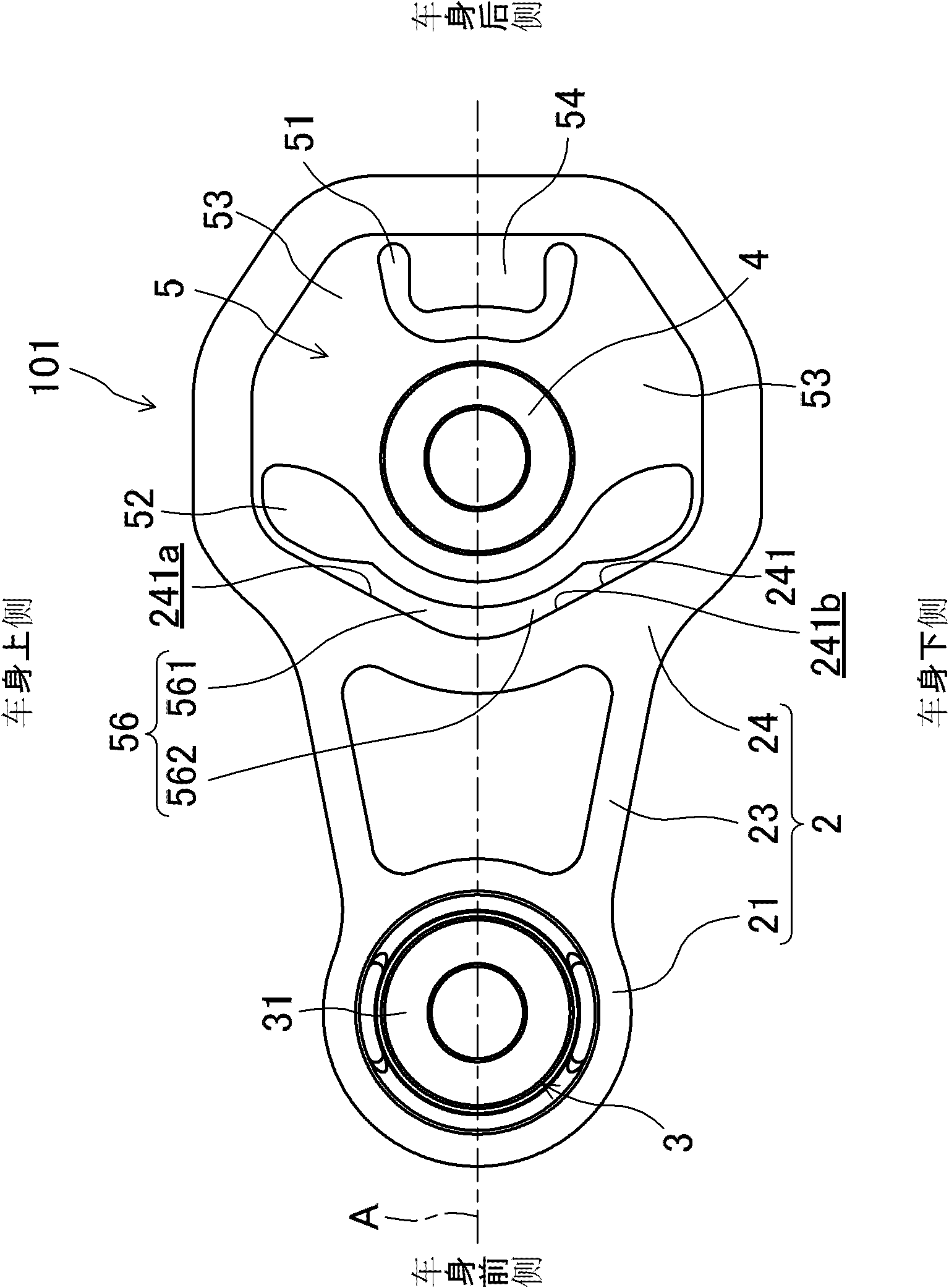

[0071] Next, a torque rod 101 according to a second embodiment of the present invention will be described.

[0072] Such as image 3 As shown, in the torque rod 101 according to the second embodiment, the structures of the second cylindrical portion and the stopper portion are different from those of the first embodiment. Therefore, the same components as those in the first embodiment are denoted by the same reference numerals, descriptions thereof are appropriately omitted, and configurations different from those in the first embodiment are mainly described.

[0073] torque rod 101 with figure 2 Unlike the illustrated torque rod 1 having the vertically flat installation portion 221 , the installation portion 241 of the torque rod 101 has inclined installation surfaces on both upper and lower sides sandwiching the reference axis A, respectively.

[0074] Specifically, the second cylindrical portion 24 is formed so that the cylindrical hole has a heptagonal shape in side vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com