Flexible Surface Spherical Mobile Robot

A mobile robot and flexible surface technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of dependence on wind energy, large load, poor load capacity, etc., and achieve the effect of simplifying the mechanical structure and improving freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

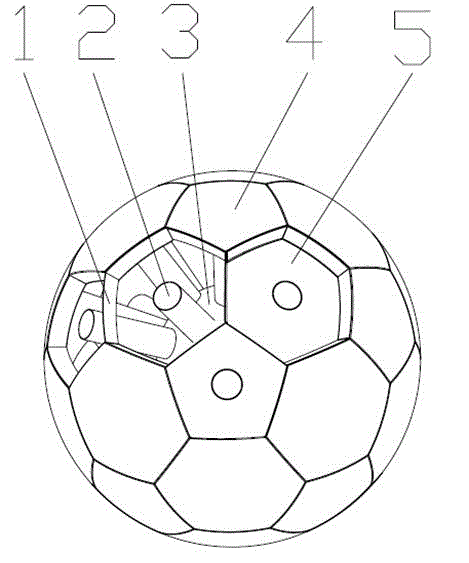

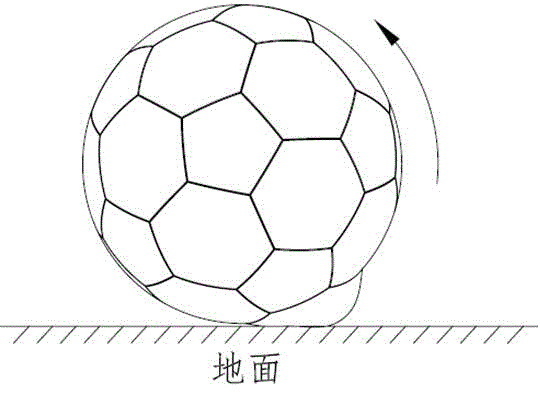

[0018] see figure 1 , the flexible surface spherical mobile robot includes an internal rigid ball (3), several support tubes (2), skeleton (1), air cavity bottom surface (5) and flexible surface (4), characterized in that: the internal The rigid ball (3) is connected to the bottom surface of each air cavity (5) through each supporting tube (2), and the bottom surface of the air cavity (5), the skeleton (1) and the flexible surface (4) constitute multiple independent air cavities; The internal rigid ball (3) is located at the center of the ball, with a built-in pneumatic drive source and control system; the support tube (2) forms an air circuit and has a solenoid valve, and the air circuit connects the air source and the air cavity. The support tube is hollow and each support tube Connected with the corresponding air cavity, the electromagnetic valve controls the on-off of each air circuit; when the robot needs to move, the air source inflates the corresponding air cavity from ...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1, and the special features are as follows: the flexible surface (4) is made of soft material and has elasticity. The support tube (2), the internal rigid ball (3), the bottom surface of the air cavity (5) and the skeleton (1) constitute the rigid structure of the spherical robot. When the robot is moving, it can inflate several independent air chambers at the same time. The deformation of each flexible surface (4) can be controlled by how much it is inflated.

Embodiment 3

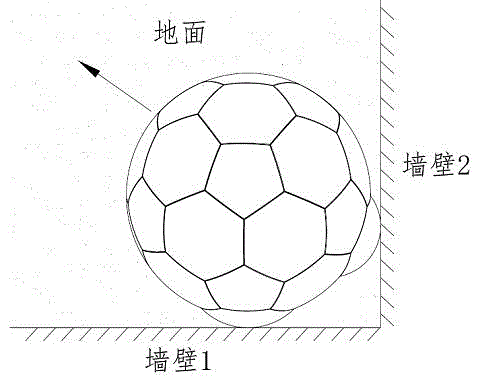

[0022] see Figure 1~Figure 3 , the spherical mobile robot with a flexible surface includes a skeleton (1), a support tube (2), an internal rigid ball (3), a flexible deformable surface (4), and an air cavity bottom surface (5).

[0023] The support tube (2), the internal rigid ball (3), the bottom surface of the air cavity (5) and the skeleton (1) constitute the rigid structure of the spherical robot;

[0024] The outer surface of the flexible spherical robot is composed of multiple flexible surfaces (4). The flexible surface is made of soft materials and has elasticity; the rigid skeleton (1) supports the entire flexible surface (4), and is connected with each elastic surface 4 and the bottom surface of the air cavity (5 ) constitute multiple independent air cavities;

[0025] The inner rigid ball (3) is located in the center of the ball, mainly for the air source device and the control system. The inner rigid ball (3) is connected with multiple support tubes (2) on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com