Automated assembly of panelized aircraft fuselages

A technology for aircraft fuselage and fuselage, which is applied in the field of automatic assembly of jigsawed aircraft fuselage, and can solve problems such as prolonging production time and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

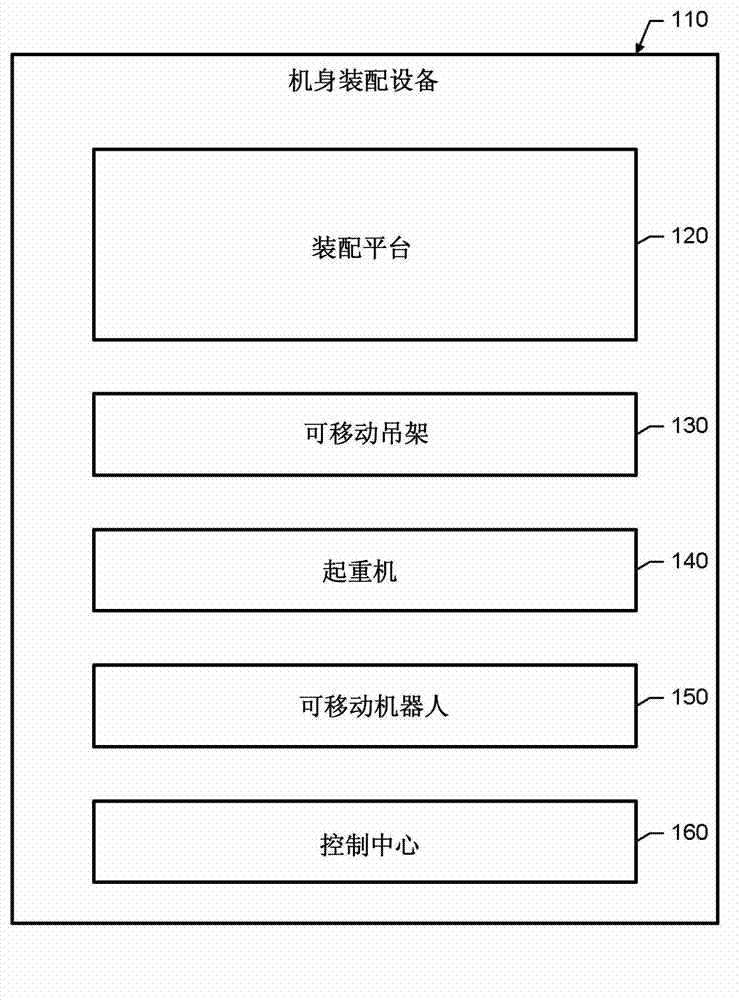

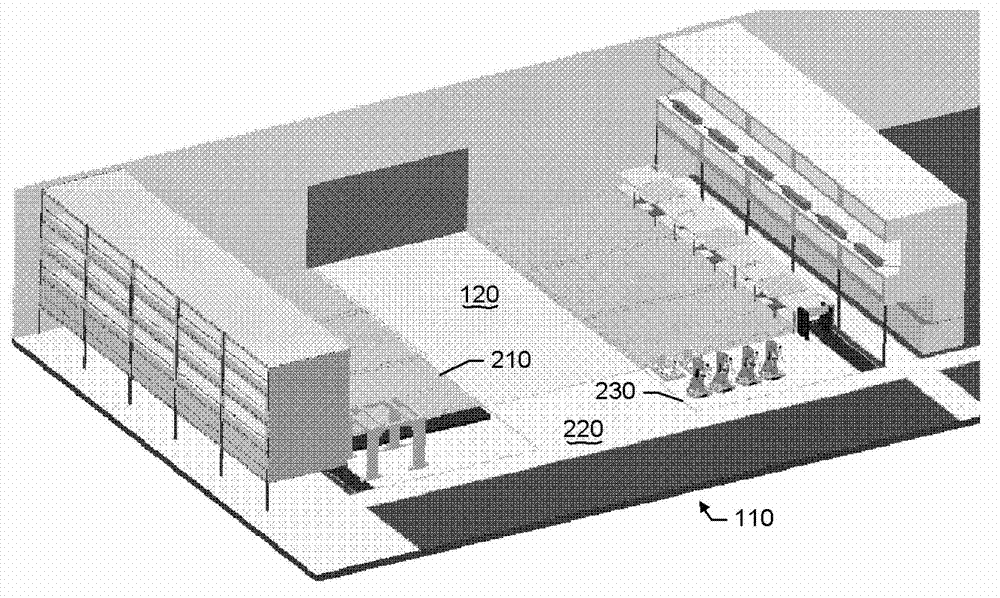

[0036] refer to figure 1 , which illustrates automated equipment 110 for assembling an aircraft fuselage. The device 110 includes an assembly platform 120 . For example, platform 120 may comprise one or more slabs of cement with suitable load bearing capacity. Cement board can be relatively flat and smooth. Unlike conventional assembly equipment, equipment 110 does not have fuselage assembly jigs and fixtures secured to platform 120 .

[0037] In some embodiments, assembly platform 120 is large enough to accommodate multiple assembly areas or cells. In each assembly cell, the fuselage can be assembled. Multiple assembly cells allow multiple fuselages to be assembled simultaneously.

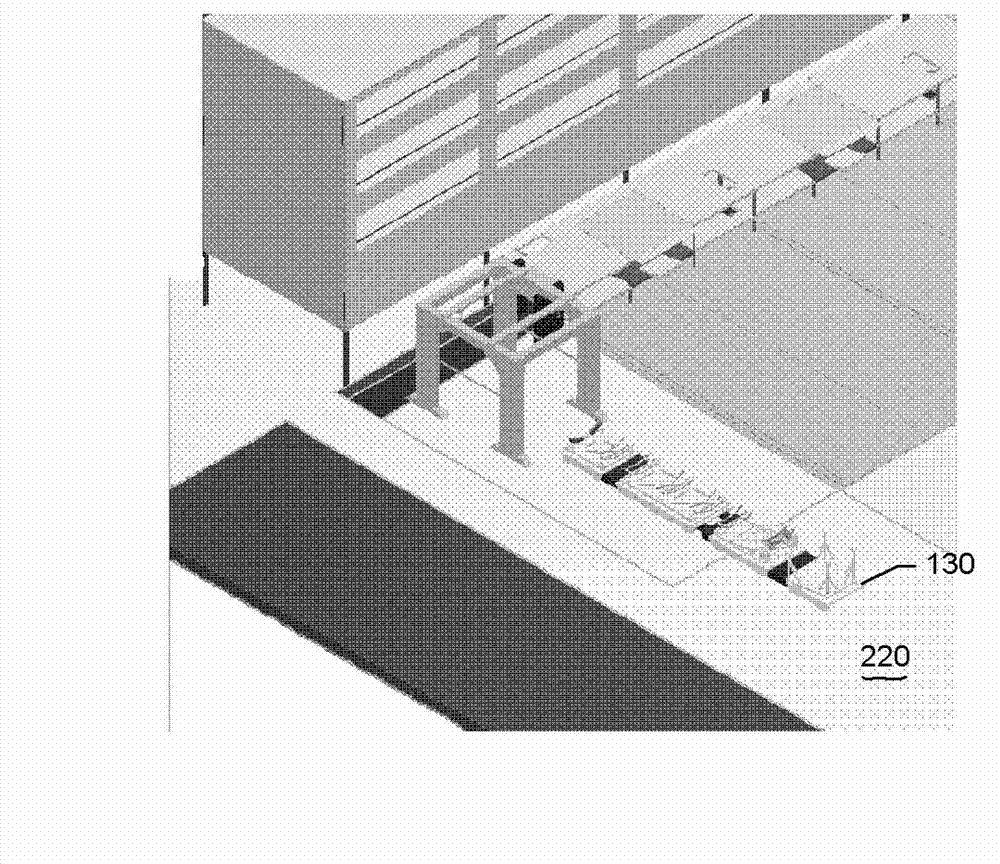

[0038] The apparatus 110 also includes a plurality of movable hangers 130 . Each pylon 130 is configured to support the fuselage keel construction and assemble the paneled fuselage in a single upright build position. A single upright build position for a paneled fuselage refers to a process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com