Filling head for filling containers

A filling and container technology, applied in the field of filling mechanism, can solve problems such as inability to fill, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

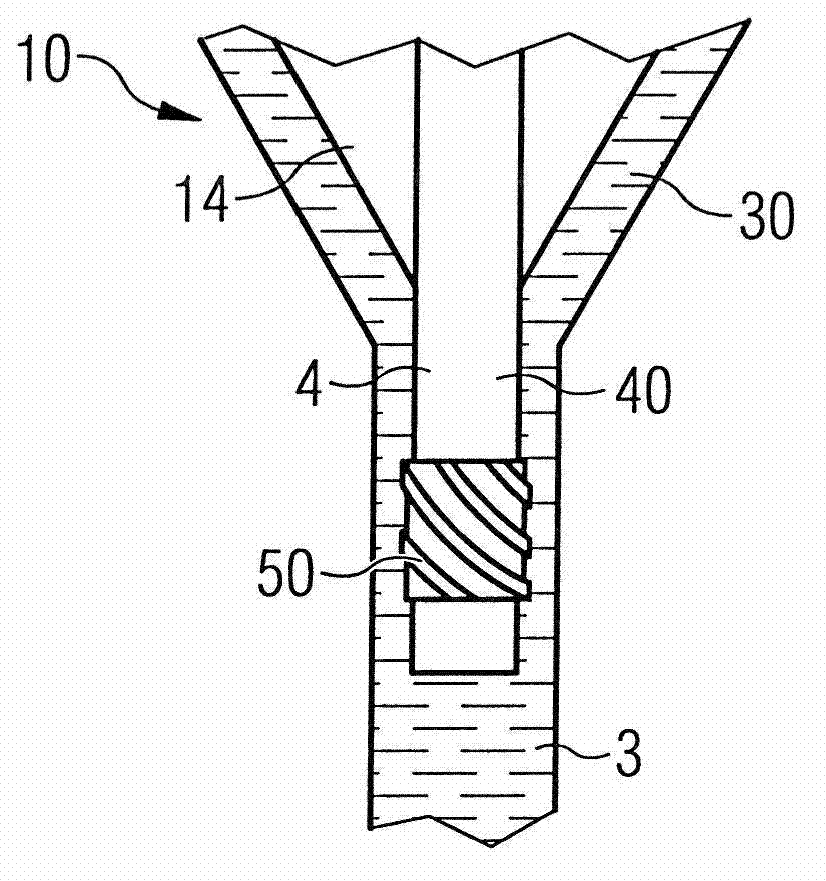

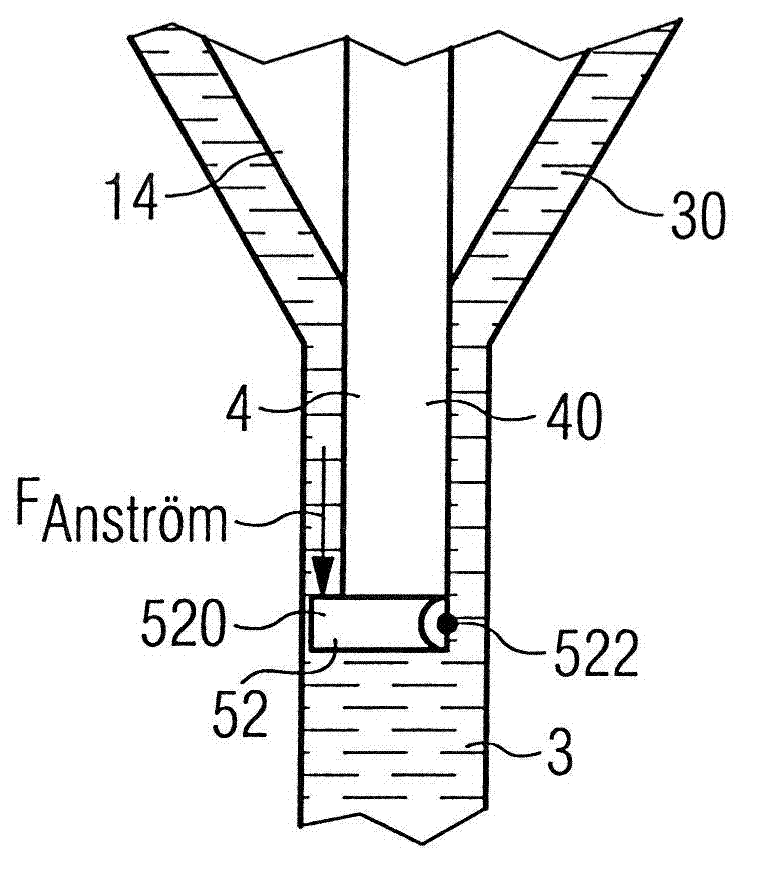

[0039] Hereinafter, preferred embodiments will be described with reference to the accompanying drawings. Here, identical, similar or identically functioning components are denoted by the same reference numerals, and repeated descriptions of such components are sometimes omitted in the following description to avoid lengthy description.

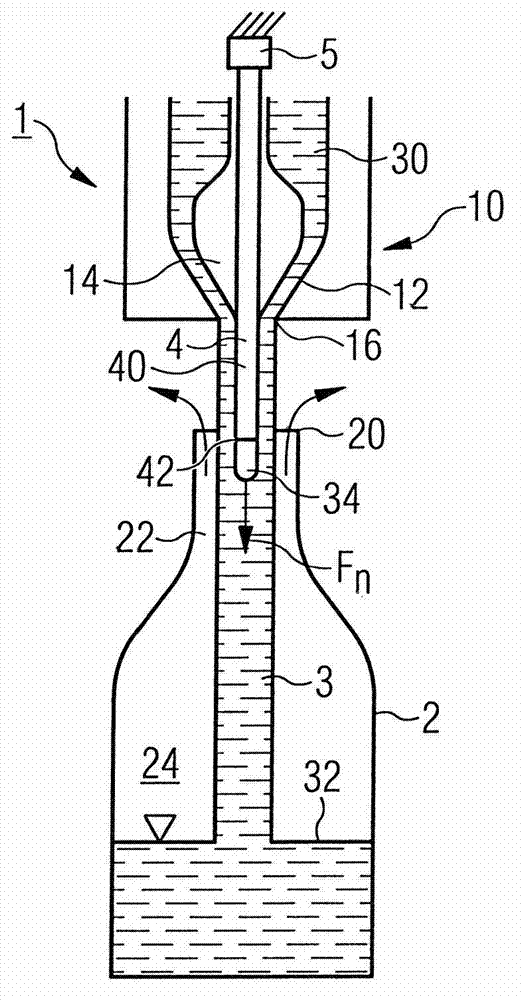

[0040] figure 1 A filling device 1 for filling a bottle-shaped container 2 with a liquid 30 is shown. The filling device 1 comprises a full flow filling part 10 for filling a container 2 with a full flow 3 . To this end, the liquid 30 flows out of the outlet opening 16 arranged substantially centrally on the container mouth 20 and flows in the form of a full liquid flow 3 through the mouth 20 and the neck 22 of the container 2 into the container interior 24 . The gas expelled from the container 2 by the raised liquid level 32 (i.e., for example, the air located in the container cavity 24) can flow into the liquid 30 of the container cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com