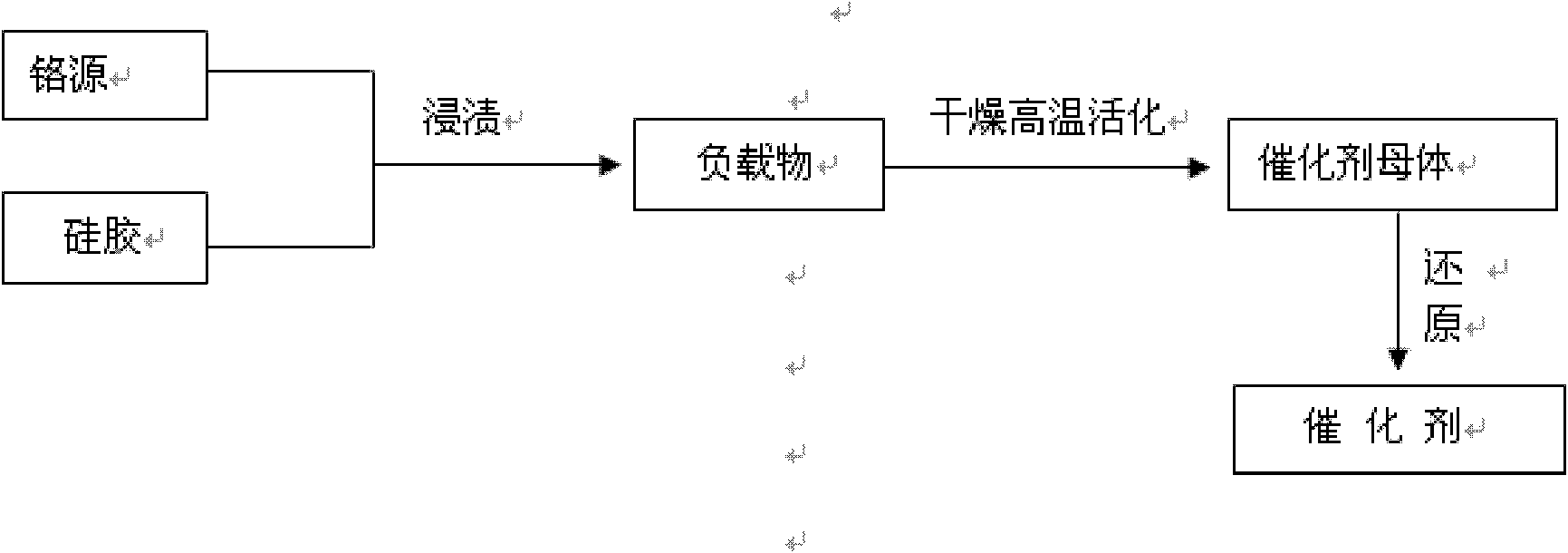

Preparation method for chromium catalyst for vinyl polymerization

A chromium-based catalyst, ethylene polymerization technology, applied in the production of bulk chemicals, etc., can solve problems that have not been seen, and achieve the effect of a wide range of melting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Weigh 0.4497 g of 50% chromium acetate solution in a 100 ml dry beaker, add 60 ml of deionized water to form a solution. Weigh 20 grams of 955 silica gel in a 1000ml dry beaker, slowly add the prepared chromium acetate solution into the silica gel under stirring, stir to make the silica gel and chromium acetate solution fully contact, and mix evenly. After soaking for 4 hours, the material was dried at 60°C for 12 hours. Move the dried load into a Φ30×500mm quartz tube, pass high-purity nitrogen gas into the bottom, activate at a constant temperature of 200°C for 2 hours, then raise the temperature to 600°C, and switch the activation gas from high-purity nitrogen when the temperature rises to 300°C In dry air, maintain 600°C for 4 hours for activation. After the activation, stop heating and lower the temperature slowly, and switch the activation gas from air to high-purity nitrogen when the temperature drops to 300°C. After the material is lowered to room temperature, ...

Embodiment 2~4

[0043] The activation temperatures of Examples 2-4 are 500°C, 700°C, and 800°C respectively, and the rest of the steps are the same as in Example 1. The polymerization activity of the prepared polyethylene and the molecular weight of the prepared polyethylene are shown in Table 1.

[0044] Table 1 embodiment 1~4 experimental result

[0045] serial number

Embodiment 5~9

[0047] The carbon monoxide reduction time of Examples 5-9 is 6 min, 10 min, 30 min, 120 min, 240 min respectively, and the remaining steps are the same as in Example 1. The polymerization activity of the prepared polyethylene and the molecular weight of the prepared polyethylene are shown in Table 2.

[0048] Table 2 embodiment 1,5,6,7 experimental result

[0049] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com