Heat and light resistant polymer composition

A composition and polymer technology, applied in the field of polymer compositions, can solve problems such as easy yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] The disclosure is now presented by way of working examples, which are intended to demonstrate the invention and are not intended to be restrictive to imply any limitation on the scope of the disclosure.

[0106] The following commercially available materials were used:

[0107] Polyester: from Eastman Chemical Products Company (Eastman TM Chemical Products) PCT polyester

[0108] glass fiber:

[0109] Fiberglass-1: from Owens Corning Composites (OCV TM Reinforcements' OCV995

[0110] Fiberglass-2: OCV952A from Owens Corning Composites

[0111] Glass fiber-3: T-127H from NEG (Nippon Electric Glass) Co., Ltd.

[0112] Titanium dioxide:

[0113] TiO 2 -1: available from DuPont Titanium Technologies R-350 - rutile TiO produced by the chloride process 2 , treated with silica and alumina.

[0114] TiO 2 -2: Available from Ishihara Sangyo Kaisha, Ltd PC-3——rutile TiO produced by the chloride method 2 , treated with silica and alumina.

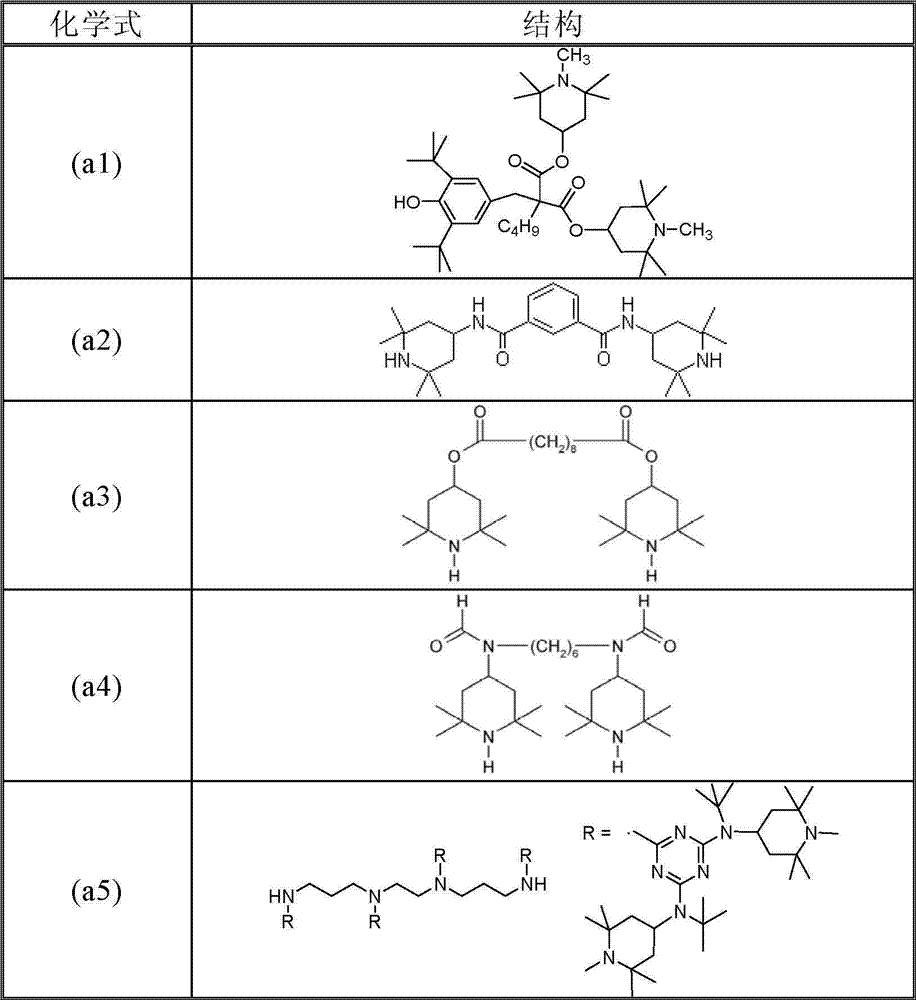

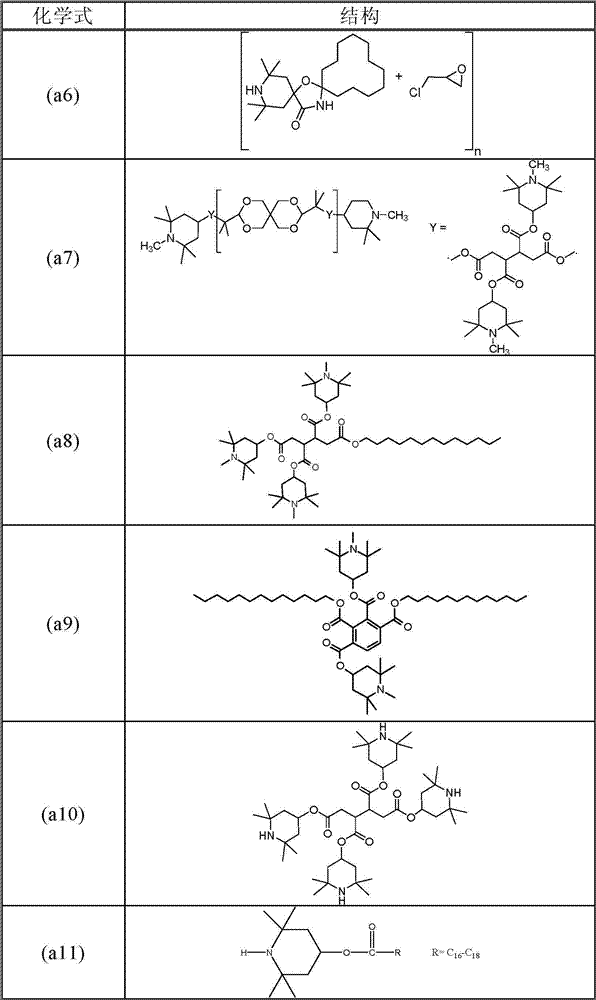

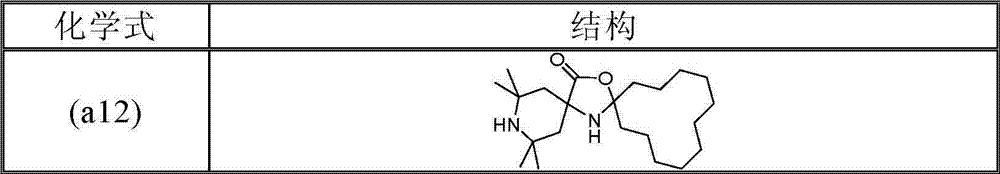

[0115] Stabilizers and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com