Method for modifying and dyeing cotton fibers by adopting tetrabutyl titanate and reactive dyes

A technology of tetrabutyl titanate and reactive dyes, applied in the direction of dyeing, fiber treatment, plant fiber, etc., can solve the problem of poor affinity between nanoparticles and polymer materials, unable to exert the performance of nanoparticles well, and fabrics are resistant to washing. problems such as poor fastness, to achieve the effect of good color fastness to sunlight, saving raw materials, and high utilization of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

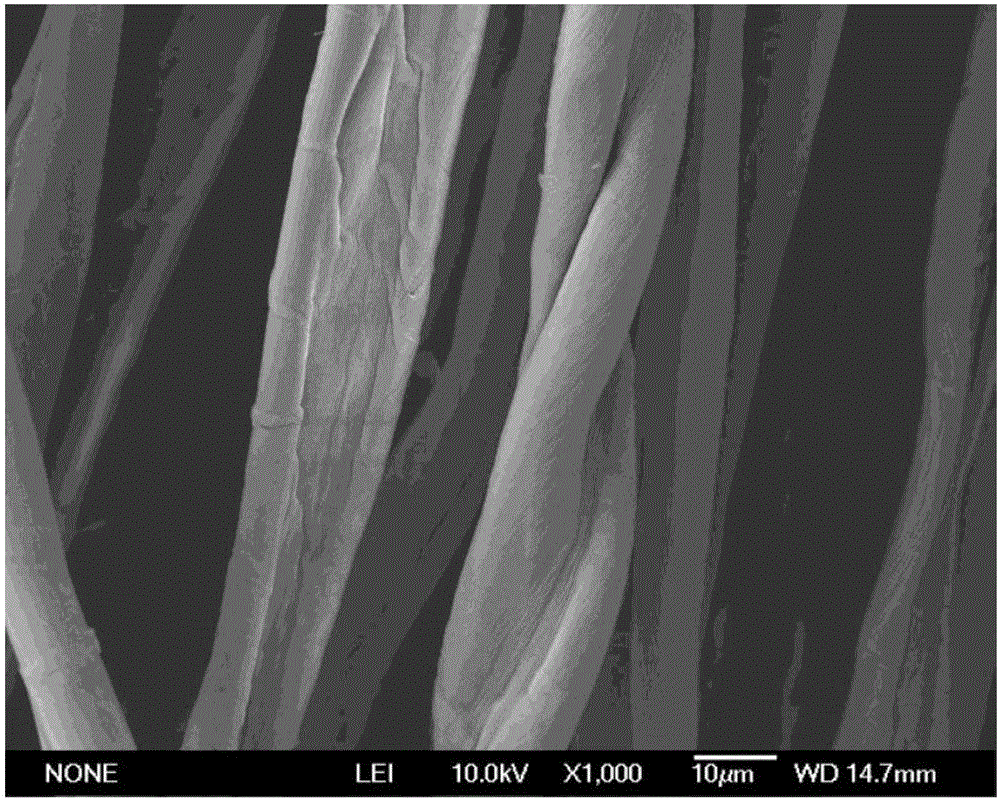

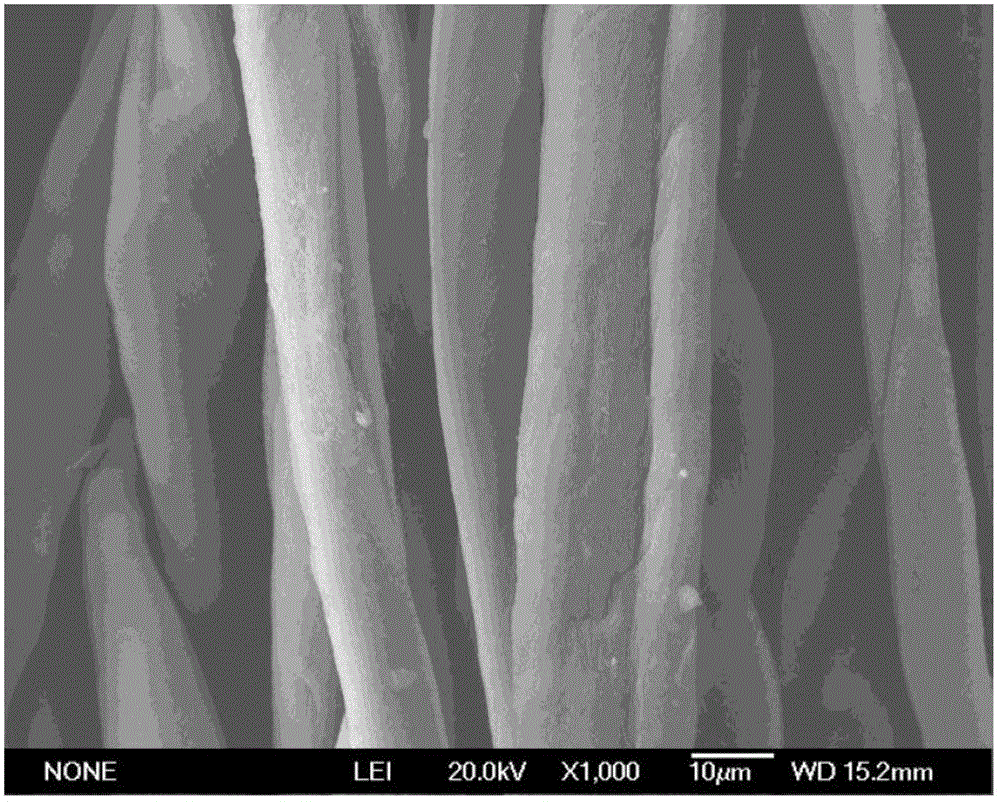

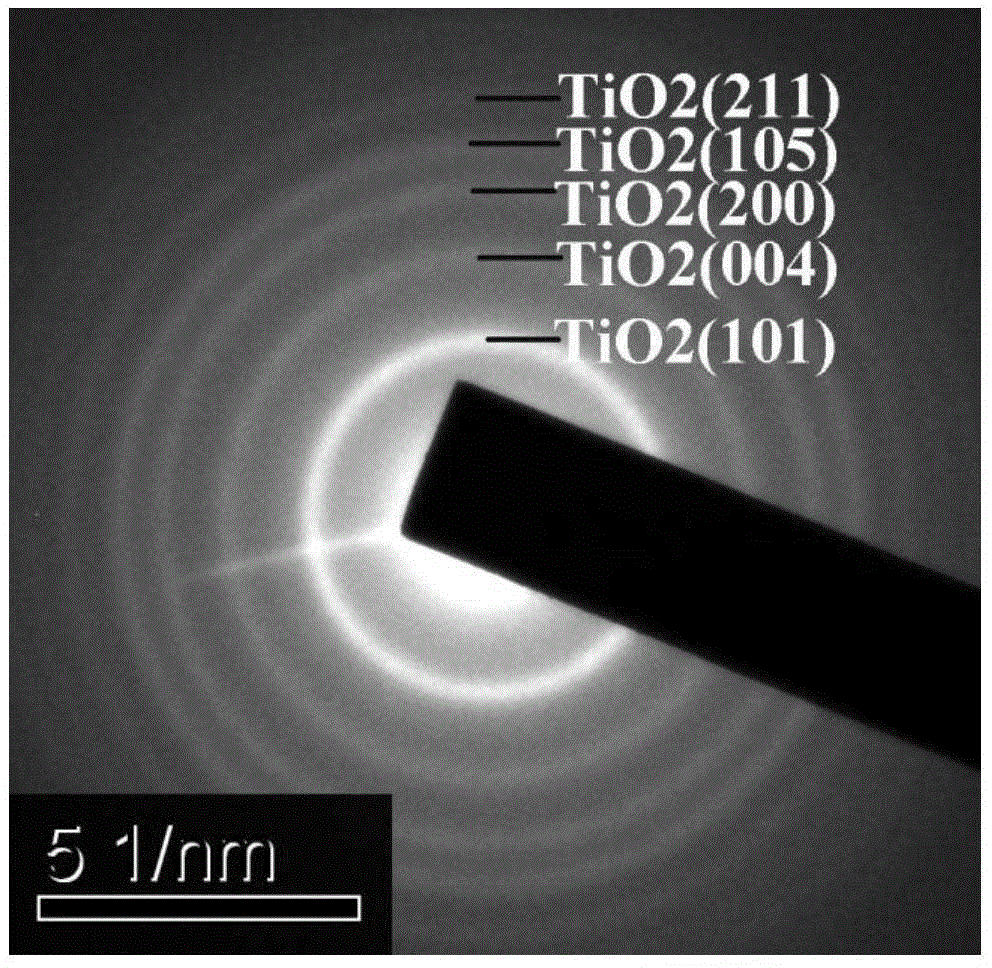

Embodiment 1

[0073] Soak 5g of cotton fiber in a sodium hydroxide solution with a mass concentration of 3.0g / L, treat it at 80°C for 50min, then wash it with absolute ethanol and deionized water at 60°C for 10min, and then wash it at 70°C Dry at ℃; weigh 0.05g of reactive Cuilan KN-G dye according to 1% of the cotton fiber mass, measure 150mL of deionized water according to the bath ratio of 1:30, and weigh 7.5g according to the volume of deionized water Sodium sulfate and 1.5g of sodium carbonate, Dissolve reactive Cuilan KN-G dye in deionized water at 40°C, put it into the pretreated cotton fiber for dyeing, add 3.75g of sodium sulfate and keep stirring, add after 10min Another 3.75g of sodium sulfate, continue to stir, after dyeing for 10min, the solution is heated up to 80°C at a rate of 1°C / min, after 10min, add 0.75g of sodium carbonate, after 15min, add another 0.75g of sodium carbonate, and keep stirring for 15min The post-dyeing is completed; according to the mass ratio of cotton ...

Embodiment 2

[0076] Soak 5g of cotton fiber in a sodium hydroxide solution with a mass concentration of 6.0g / L, treat it at 100°C for 30min, then wash it with absolute ethanol and deionized water at 60°C for 20min, and then wash it at 90°C Drying under dry conditions; Weigh 0.1g of reactive Cuilan KN-G dye according to 2% of the cotton fiber mass, measure 250mL of deionized water according to the bath ratio of 1:50, and weigh 17.5g of deionized water according to the volume of deionized water Sodium sulfate and 5g of sodium carbonate, dissolving active Cuilan KN-G dye in deionized water at 50°C, putting it into the pretreated cotton fiber for dyeing, adding 8.75g of sodium sulfate and stirring continuously, and adding another after 15min 8.75g of sodium sulfate, continue to stir, after dyeing for 15min, the solution is heated up to 90°C at a rate of 2°C / min, add 2.5g of sodium carbonate after 15min, add another 2.5g of sodium carbonate after 10min, and keep stirring, dyeing after 10min Com...

Embodiment 3

[0079] Soak 5g of cotton fiber in a sodium hydroxide solution with a mass concentration of 4g / L, treat it at 90°C for 40min, then wash it with absolute ethanol and deionized water at 60°C for 15min, and then wash it at 80°C Drying at the bottom; weigh 0.06g of reactive Cuilan KN-G dye according to 1.2% of the cotton fiber mass, measure 200mL of deionized water according to the bath ratio of 1:40, and weigh 12g of sodium sulfate according to the volume of deionized water and 3g of sodium carbonate, dissolve the active Cuilan KN-G dye in deionized water at 45°C, put it into the pretreated cotton fiber for dyeing, add 6g of sodium sulfate and keep stirring, add another 6g of sodium sulfate after 13min , continue to stir, after dyeing for 13 minutes, the solution is heated to 85°C at a rate of 1.5°C / min, 1.5g of sodium carbonate is added after 13 minutes, and another 1.5g of sodium carbonate is added after 20 minutes, and the dyeing is completed after 20 minutes; The mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com