Integrated equipment quick aligner and equipment aligning method

An integrated, equipment-based technology, applied to mechanical equipment, supporting machines, engine frames, etc., can solve problems such as limited adjustment accuracy, limited application range, and complicated procedures, and achieve accurate adjustment accuracy, wide application range, and simple procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with the accompanying drawings and specific embodiments.

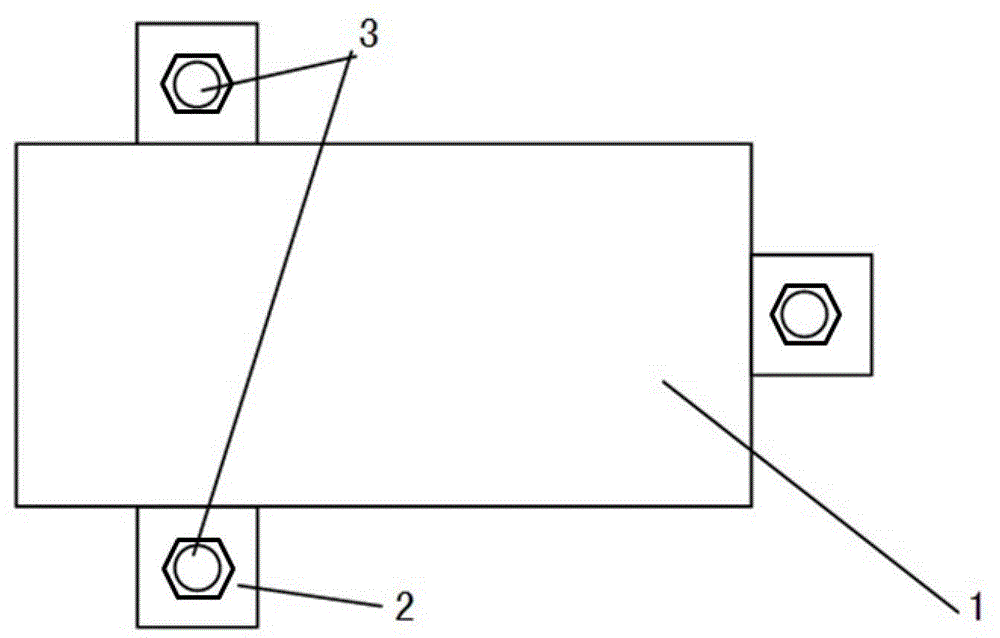

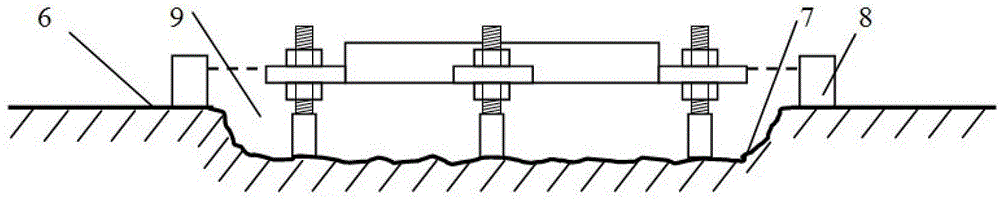

[0028] Such as figure 1 and figure 2 As shown, a kind of integrated equipment quick aligner, said aligner includes a center pad iron 1, three adjustment ears 2 are arranged on the periphery of said center pad iron 1 according to an isosceles triangle, and said three adjustment ears Ear 2 is located at the three vertices of the isosceles triangle;

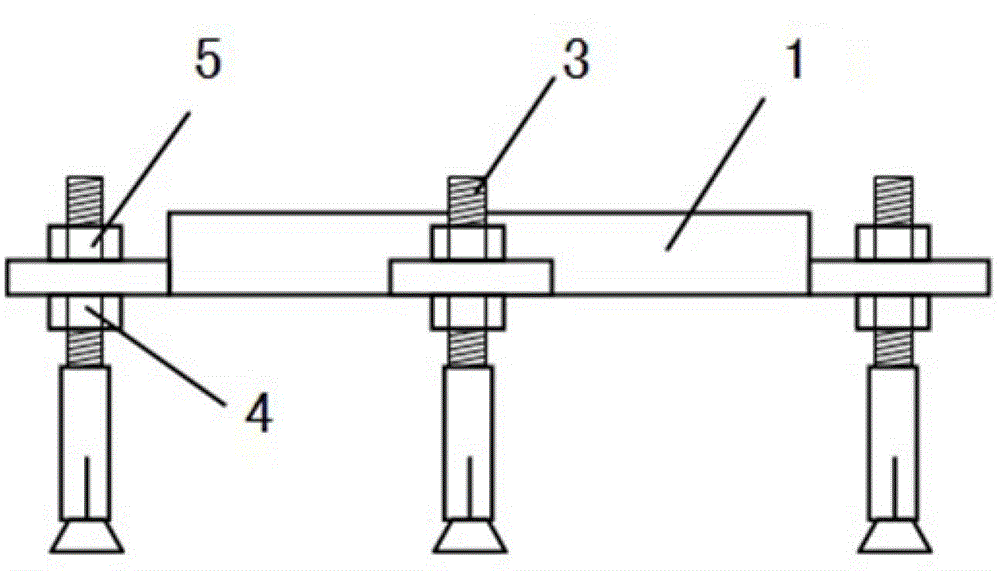

[0029] Wherein, the center of three adjustment ears 2 is drilled, and an adjustment bolt 3 is pierced in any hole, and an adjustment nut 4 and a fixed nut 5 are screwed on the adjustment bolt 3, and the adjustment nut 4 is located at the adjustment ear 2 The fixing nut 5 is located above the adjusting ear 2 .

[0030] The center pad 1 is rectangular, and the center pad 1 and the adjustment ear 2 are welded together by steel plates, the adjustment bolt 3 is an expansion bolt, the lower plane of the center pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com