Heating device using industry kiln stove waste heat

A heating device and kiln technology, which can be applied to household heating, process efficiency improvement, furnaces and other directions, can solve problems such as increasing production costs, uneconomical, and polluting the environment, and save energy, reduce pollution, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

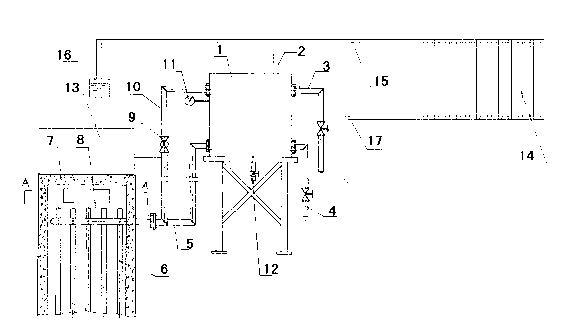

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0010] Referring to the accompanying drawings, the serpentine coil 8 is installed at the entrance of the flue in the furnace body 7 of the kiln, and several kiln hot air pipes 6 perpendicular to the coil 8 are arranged between the pipelines of the coil 8; The two ends of 8 pass through the furnace body 7, wherein one end communicates with the lower circulation pipe 5 installed below the thermal insulation water tank 1 through a flange, and the other end communicates with the upper circulation pipe 1 installed above the thermal insulation water tank 1 through another flange 0 is connected. The thermal insulation water tank 1 is installed on a position higher than the body of heater 7 by a support, and an outlet pipe 3 and a water replenishment pipe 4 are installed on the top of the thermal insulation water tank 1 other side. In order to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com