External casing packer simulation test device

A simulation test and simulation device technology, applied in the field of external packer simulation test device, can solve the problems of increasing drilling time and cost, oil layer pollution, and few detection indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

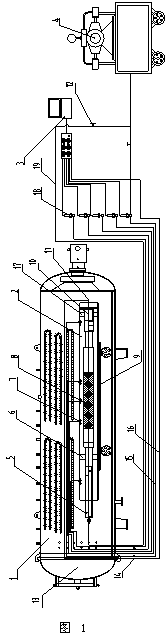

[0018] Such as figure 1 as shown, figure 1 It is a structural diagram of the simulation test device for the external packer of the present invention. The external packer simulation test device consists of a well temperature simulation device 1, a simulated wellbore 2, a measurement and control system 3, a pressure test pump 4, a test joint 5, a first centralizer 6, a test joint 7, an external packer 8, a test Trolley 9, plug 10, temperature sensor 11, setting pipeline valve 12, hatch 13, pipeline valve 14, pressure measuring pipeline 15, temperature measuring wire 16, second centralizer 17, pressure sensor 18 and setting pipeline 19 . The well temperature simulation device 1 is located outside the simulated wellbore 2, which is an external hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com