Wafer acceptance test (WAT) breakdown voltage test device and method

A technology of breakdown voltage and testing device, applied in the direction of testing dielectric strength, etc., can solve the problems of increasing production cost, limiting production efficiency, time-consuming and labor-intensive, etc., achieving the effect of effective testing, reducing debugging time, and reducing necessity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

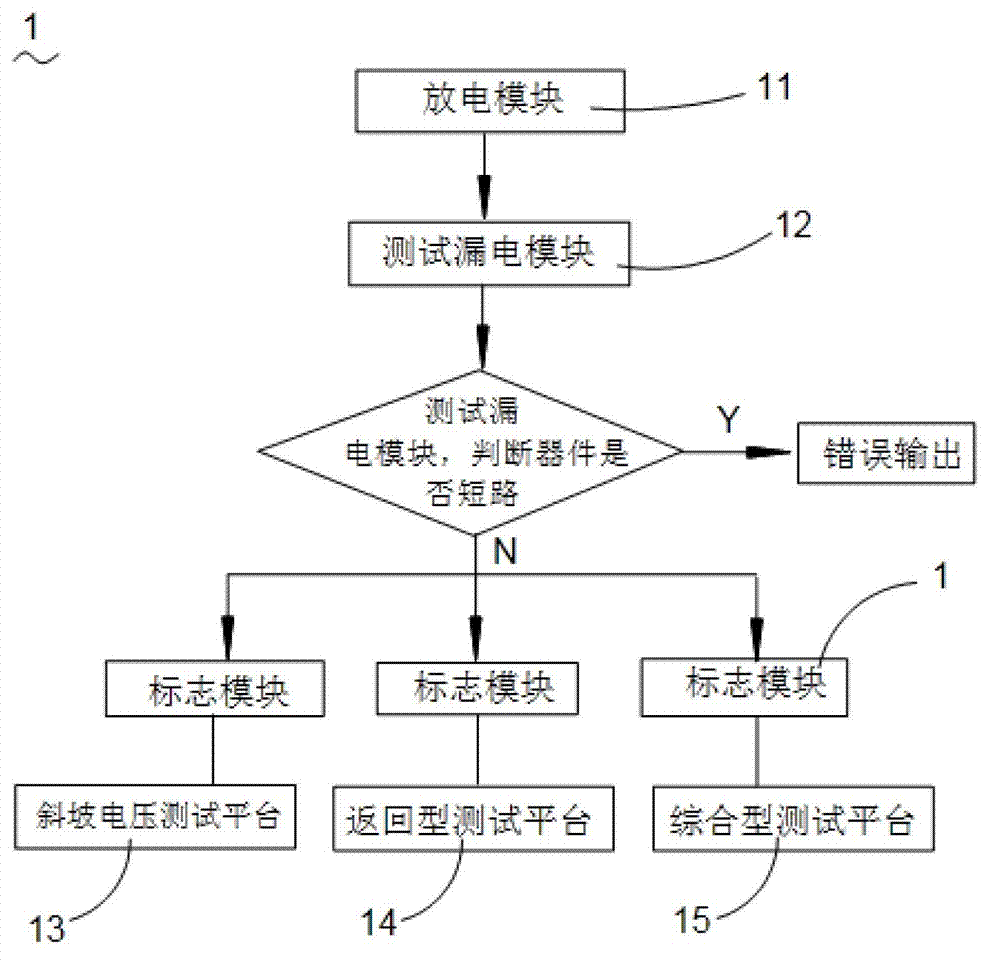

[0026] see figure 1 , figure 1 Shown is a schematic diagram of the frame structure of the breakdown voltage testing device for the wafer acceptability testing of the present invention. The breakdown voltage testing device 1 includes a discharge module 11, a leakage test module 12, and a slope voltage for performing a breakdown voltage test on the semiconductor device (not shown) after the leakage test module 12 determines that it is not short-circuited. A test platform 13 , a return-type test platform 14 , and a comprehensive test platform 15 .

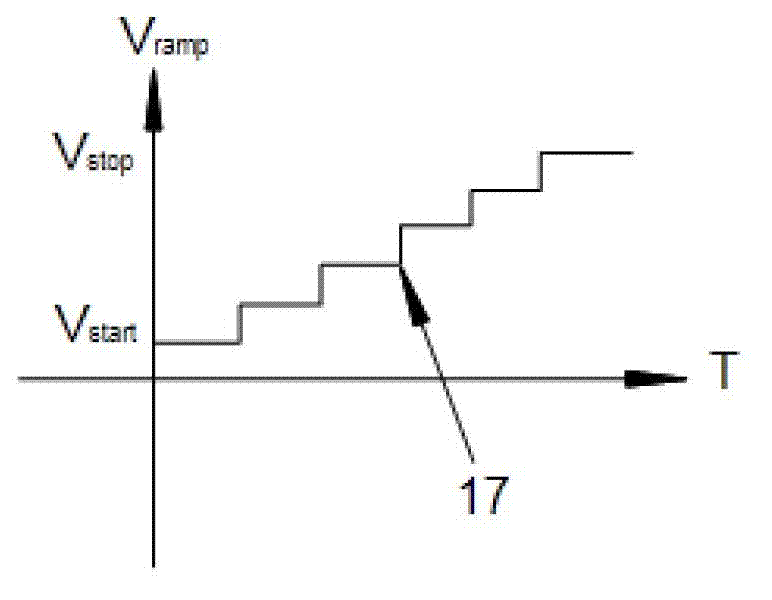

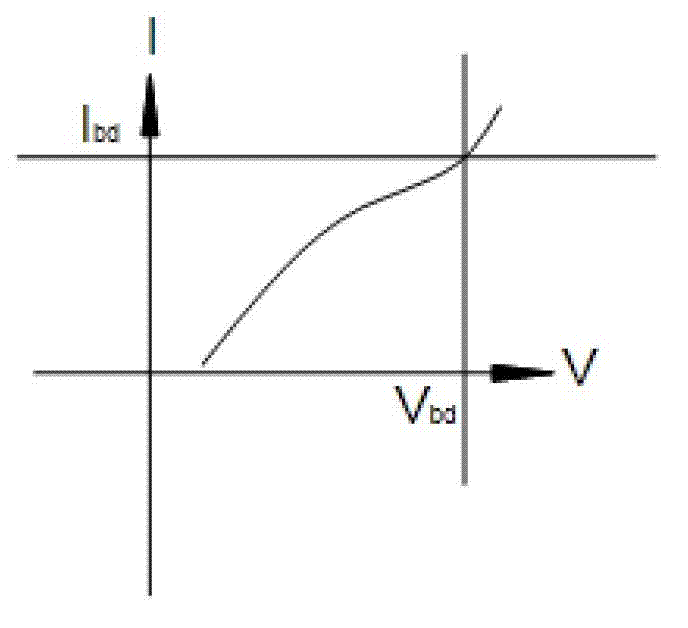

[0027] Please refer to Figure 2(a), Figure 2(b), and see figure 1 , Figure 2(a) shows the V-T relationship diagram in the ramp voltage test. Figure 2(b) shows the V-I relationship diagram in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com