Display unit and method of manufacturing the same, electronic apparatus, illumination unit, and light-emitting device and method of manufacturing the same

A technology of light-emitting devices and display units, applied in the direction of electric solid-state devices, electroluminescence light sources, electric light sources, etc., can solve the problems that light is not fully taken out, brightness cannot be obtained, etc., and achieve brightness, utilization efficiency and luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

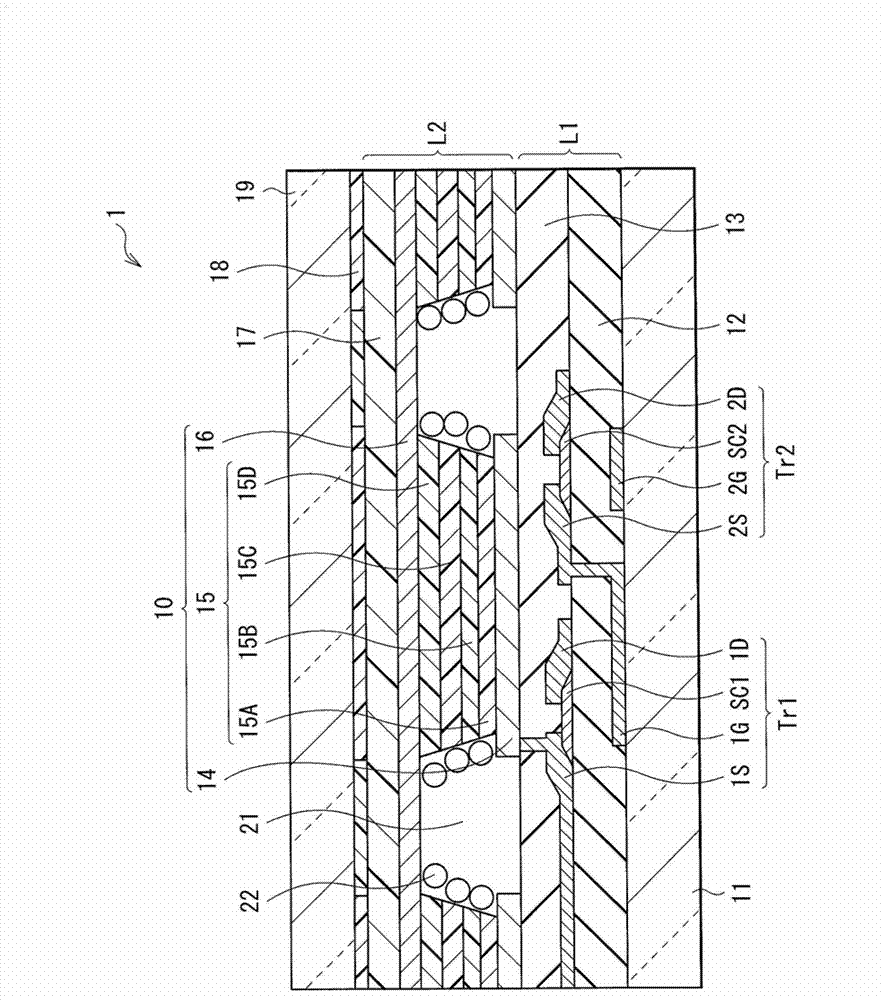

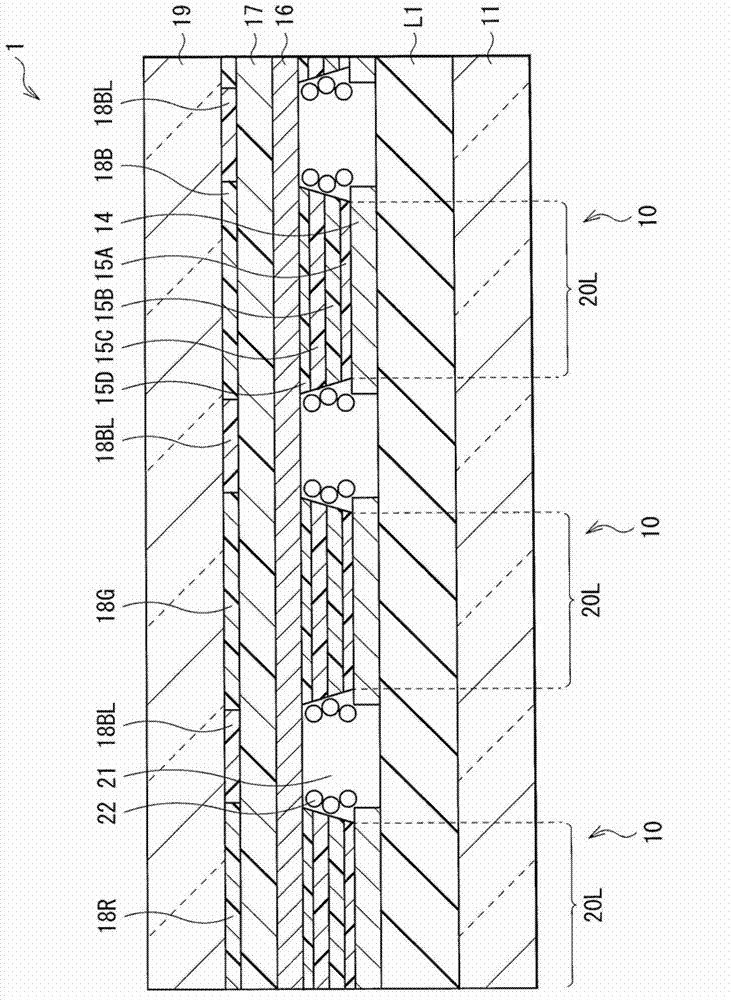

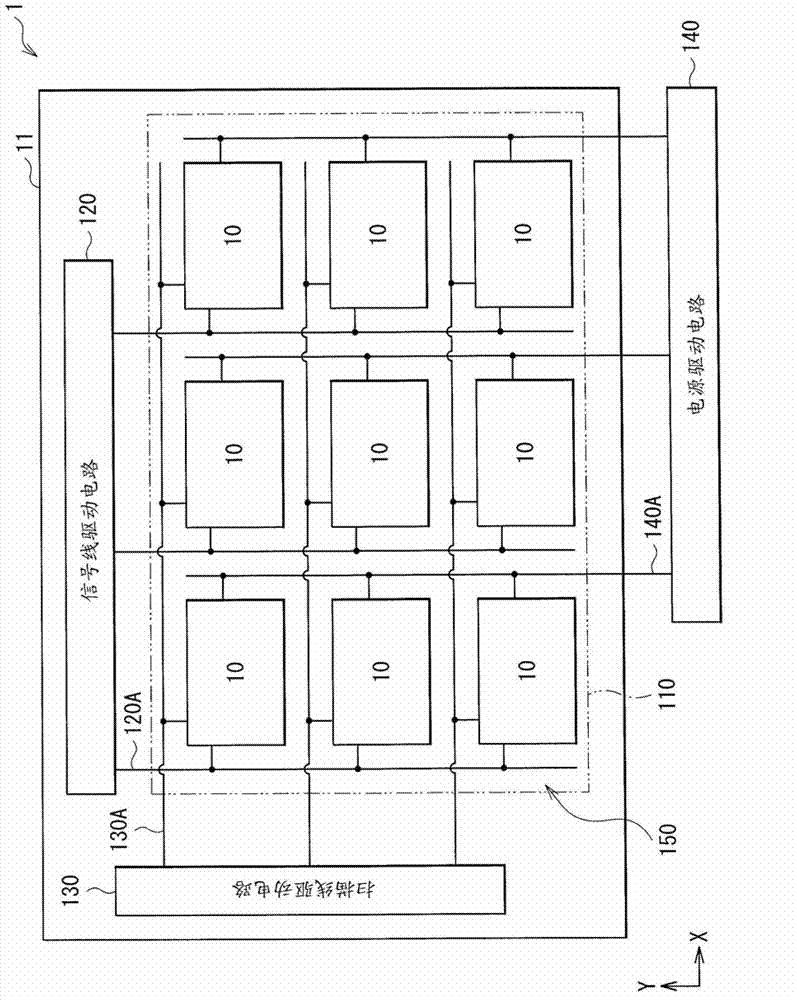

[0233] According to the above-described manufacturing method, light emitting devices 1010R, 1010G, and 1010B are formed, which include an organic layer 1011 emitting blue light (Embodiment 1) or ultraviolet light (Embodiment 2) as an excitation light source, and forming a wavelength conversion portion. The wavelength conversion portion is formed by sequentially stacking the wavelength conversion layer 1012 and the wavelength selection film 1013A from the side closer to the upper electrode 1017 between the upper electrode 1017 and the protective layer 1018. In addition, as a comparative example, a display unit including red, green, and blue light emitting devices, each light emitting device including only the wavelength conversion layer 1012 formed on the upper electrode 1017, was formed. In addition, a display unit is formed in which the wavelength selection film 1013B is formed under the wavelength conversion layer 1012 of the wavelength conversion portion, as Examples 3 and 4,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap