Pouring method for motor stator connector box

A technology of generator stator and casting method, applied in the direction of manufacturing motor generators, electromechanical devices, electrical components, etc., can solve the problems of low work efficiency, large workload, long time, etc., to achieve convenient operation, save maintenance costs, reduce The effect of repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below with reference to accompanying drawing and embodiment:

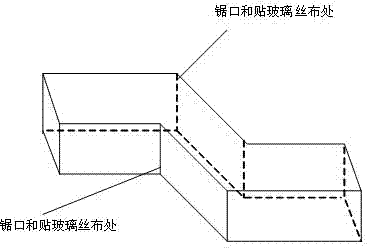

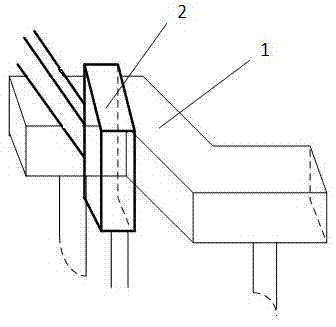

[0025] attached figure 1 As can be seen from 4, 1. A generator stator joint box pouring method comprises the steps:

[0026] 1) Put the Z-shaped insulation box into the drying oven, set the temperature of the drying oven to 80 degrees, and dry for two hours;

[0027] 2) Take the Z-shaped insulation box out of the drying oven, saw off the top cover of the insulation box; remove 3cm from the left and right ends of the sawn top cover; saw off the insulation box, and divide the insulation box into left and right parts, Wipe all parts of the sawn insulation box with alcohol;

[0028] 3) Use toluene or absolute ethanol to clean the joints and various parts of the insulation box;

[0029] 4) Install the Z-shaped insulation box, connect the insulation boxes sawn left and right into one; put the top cover of the sawn insulation box into the insulation box, use it as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com