Hot air heating system for accurately heating target ball grid array (BGA)

A technology of hot air heating and hot air, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc. It can solve the problems of not being able to know the BGA temperature, the board cannot be used again, and the components are burned, so as to achieve simple structure and easy operation. Stabilization, thermal process stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

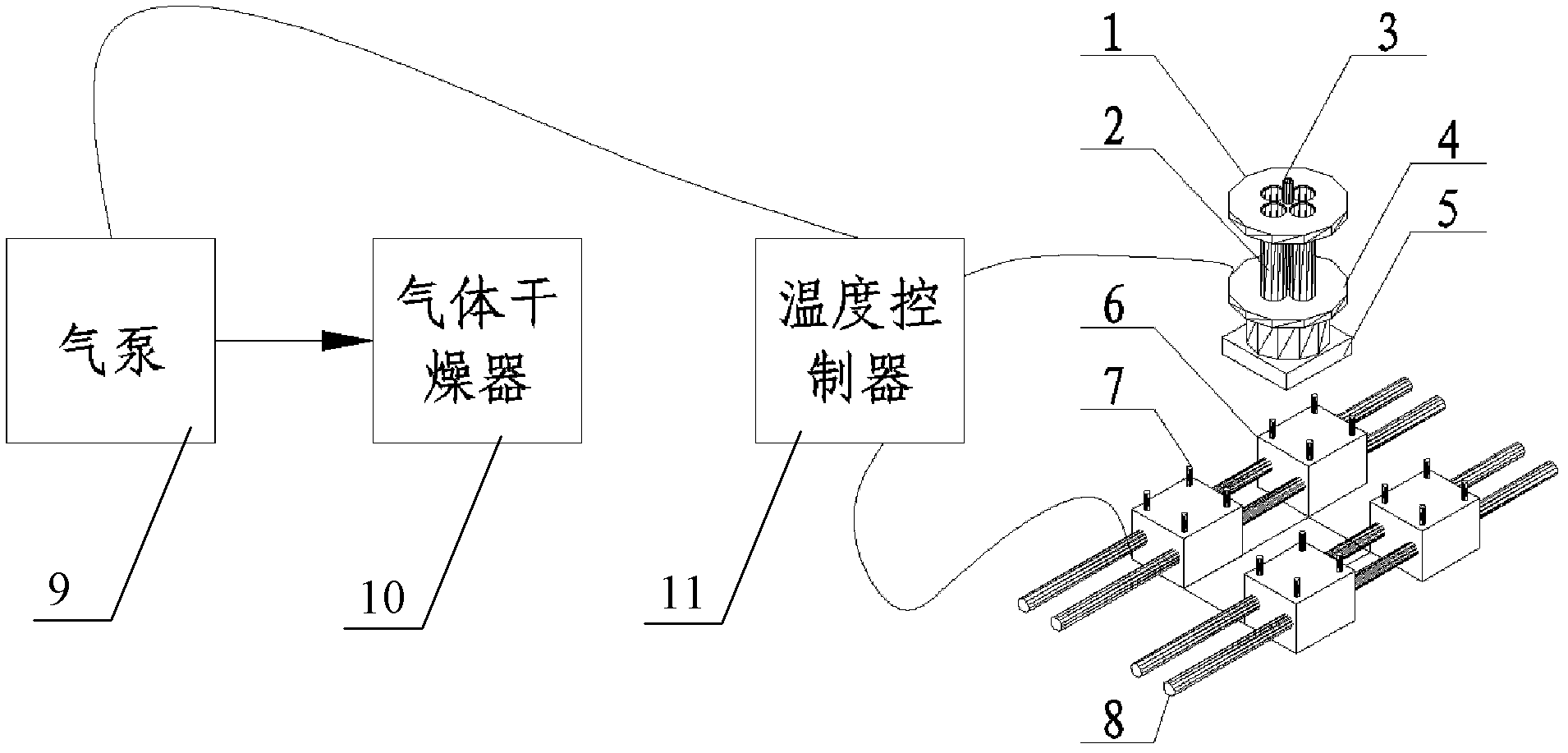

[0012] As shown in the accompanying drawings, it is a schematic diagram of the hot air heating system for realizing accurate heating of the target BGA of the present invention. In the present invention, the air pump is connected with the gas dryer, and the gas dryer removes the water vapor generated during the compression process. The front end installation temperature of the hot air nozzle device 1 is Controller, the temperature controller controls the temperature of the whole system, the hot air nozzle device 1 includes a hot air pipe 2 for heating the gas flowing through the hot air pipe, and also includes a suction nozzle air pipe 3 for BGA Adsorbed on the suction nozzle, a gas mass flow sensor 4 is installed under the hot air pipe 2 to monitor the quality and flow of the hot air in real time, and transmit the quality and flow data to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com