Scrap bounce prevention mold applied to punching of light-emitting diode (LED) bracket

A technology for LED brackets and molds, which is applied in the field of LED bracket punching molds, can solve problems such as waste bounce, achieve cost reduction, improve labor efficiency, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

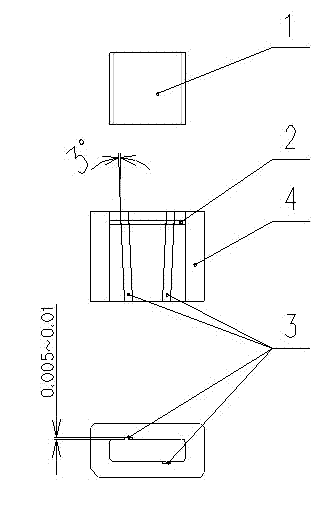

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the anti-scrap bounce-back mold applied to the punching of LED brackets, the mold includes a punch 1 and a die 2 adapted to the punch 1, and the opposite side wall of the punch 2 is provided with a recessed And the groove 3 inclined to the center line of the side wall. The opposite side wall of the die is also provided with a groove concave inward and inclined to the center line of the side wall, and the inclination direction of the groove is opposite to the inclination direction of the groove on the opposite side. The two grooves extend downward and gradually approach the center line. The depth of the groove is about 0.001 mm to 0.01 mm. The inclination of the groove is about 3 degrees with the central line, and the angle is not too large, which will generate a relatively large frictional force.

[0013] In the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com