Bottom die single-side locking mechanism

A locking mechanism and bottom mold technology, which can be applied to other household appliances, household appliances, applications, etc., can solve the problem of large volume of the bottom mold locking device, and achieve the effect of reducing the size of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

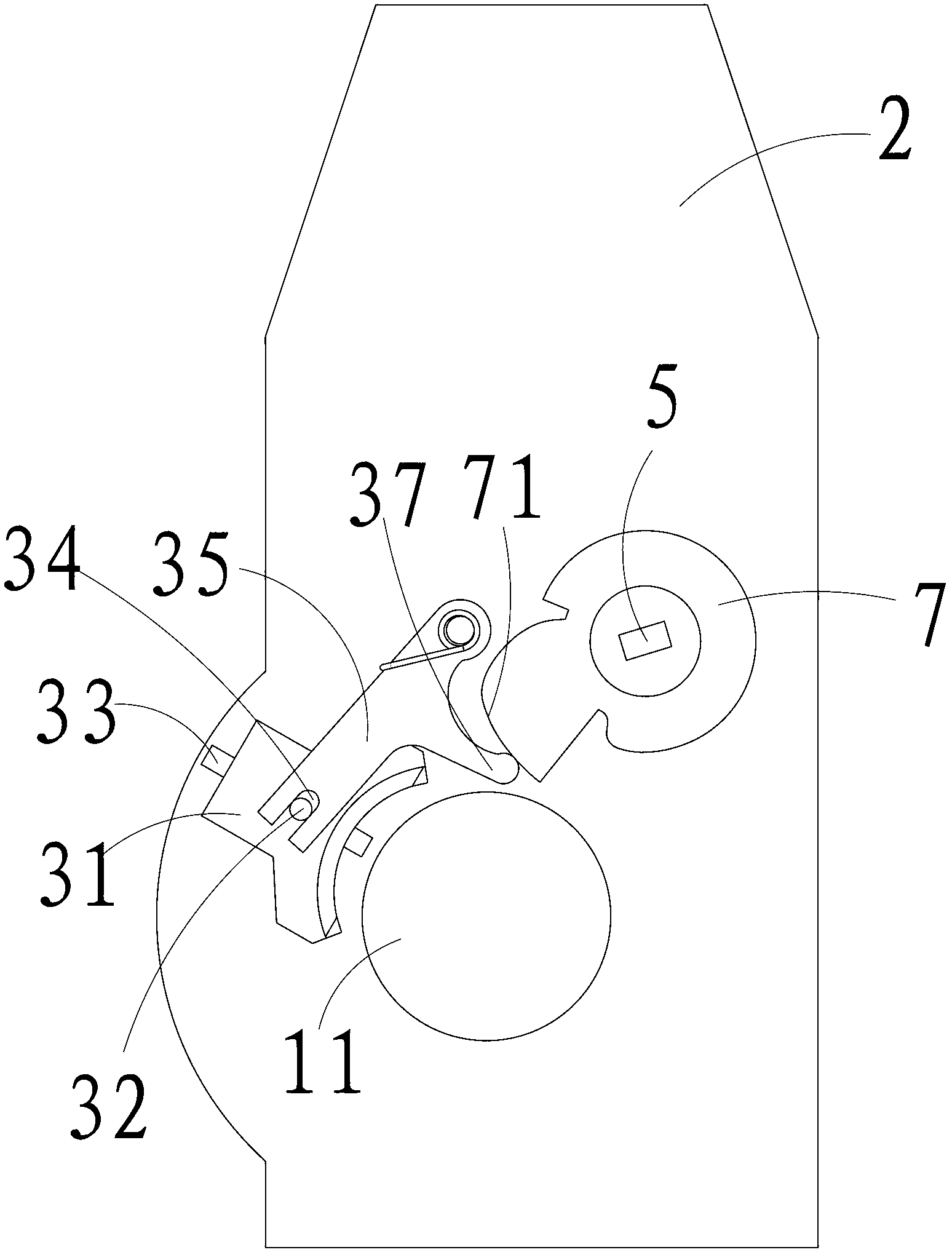

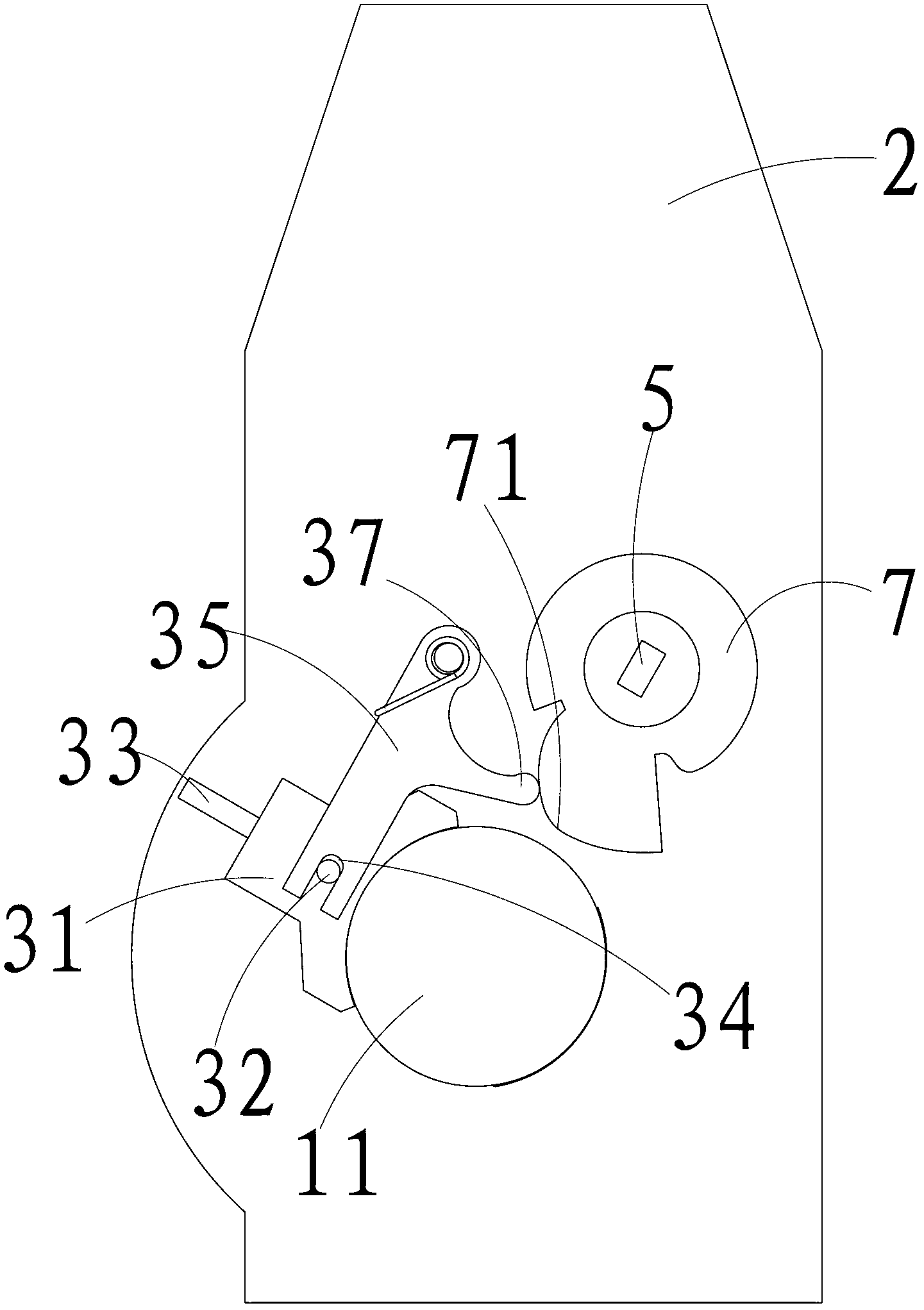

[0017] As shown in the accompanying drawings, a bottom mold unilateral locking mechanism, which is installed on the blow molding machine, includes a rotating shaft 5 that can rotate around its own axis, a power source that drives the rotating shaft 5 to rotate, and is fixed on the rotating shaft 5. The active connecting block 7, the driven connecting block 35 cooperating with the active connecting block 7, the slide block 31 that is slidably arranged in the horizontal direction, the bottom mold locking mechanism also includes a guide rail 33 that is arranged on the frame 2 in the horizontal direction, and the sliding The block 31 is slidably provided along the guide rail 33 .

[0018] Specifically, one end of the driven connection block 35 is rotationally connected to the frame 2, and the other end is connected to the slide block 31. The active connection block ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap