Variable electro-hydraulic servo hydraulic transformer

A hydraulic transformer and electro-hydraulic servo technology, applied in fluid pressure converters, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve load pressure and load flow coupling, load flow is uncontrollable, and cannot be generalized and other issues to achieve the effect of low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

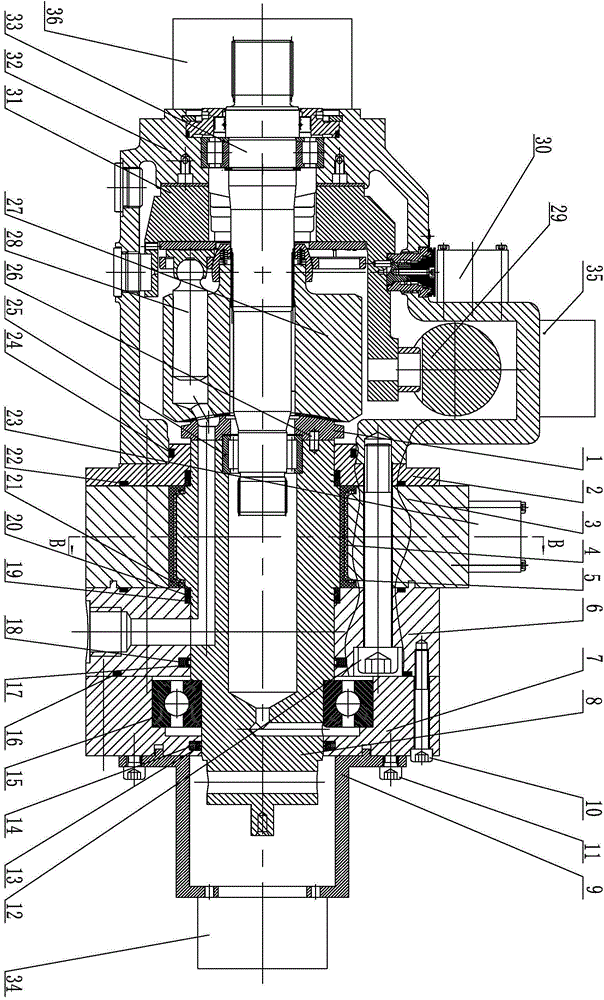

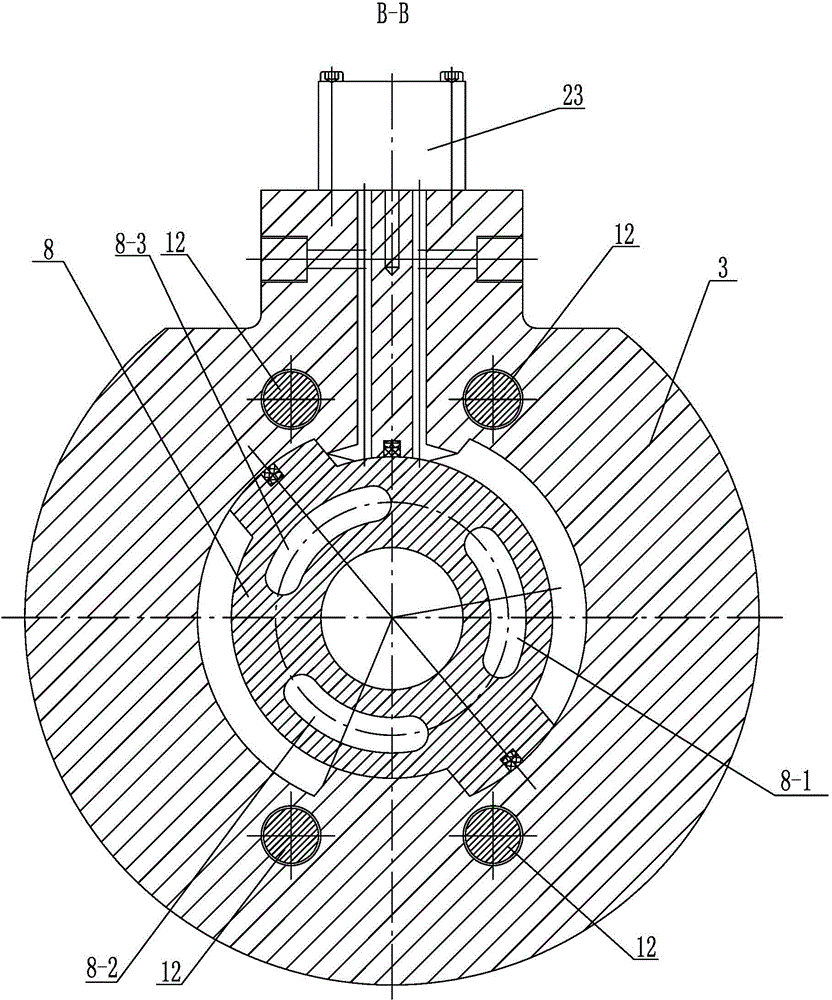

[0017] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, a variable electro-hydraulic servo hydraulic transformer in this embodiment includes a valve plate servo mechanism and a swash plate servo mechanism;

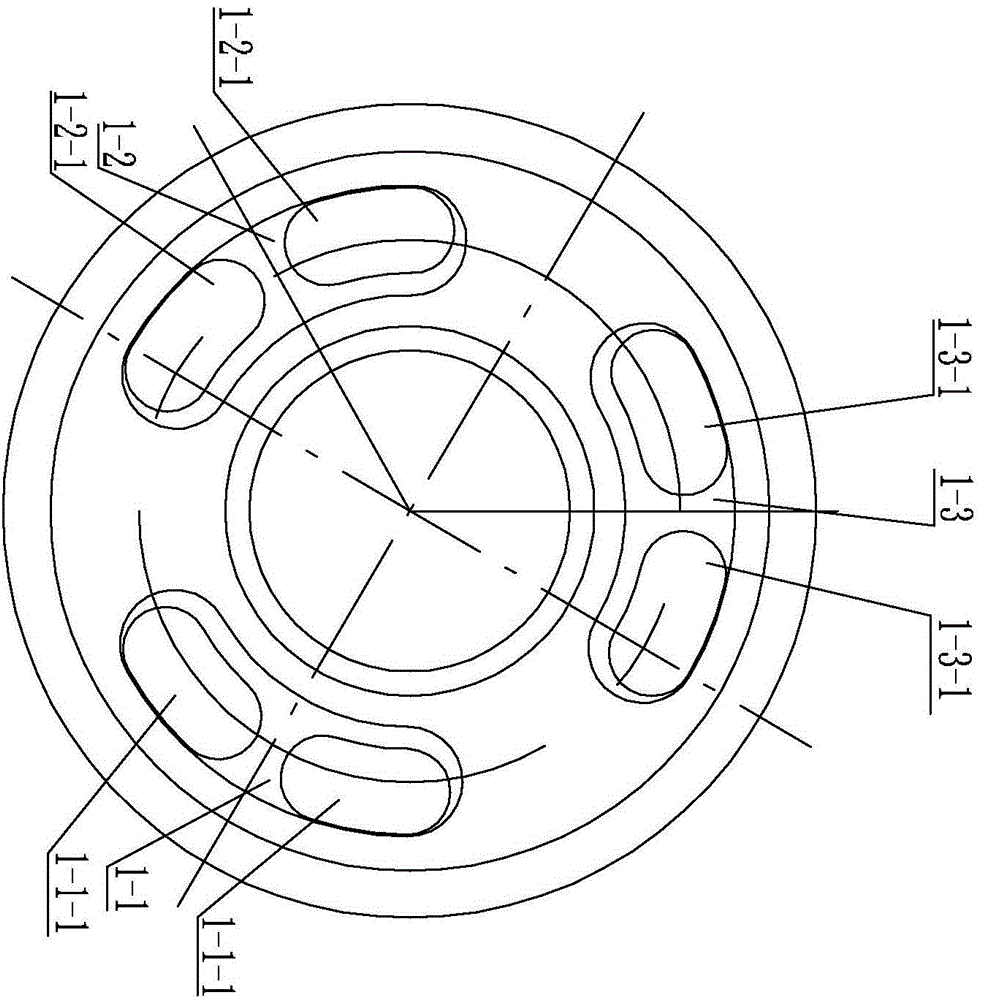

[0018] The valve plate servo mechanism includes a valve plate 1, an end cover 2, a valve housing 6, a bearing cover 7, a bearing 15, a first hydraulic control valve 23 and a swing motor, and the swing motor includes a motor housing 3 and a vane shaft 8 , the distribution plate 1 is detachably connected to the vane shaft 8, the motor housing 3 is arranged between the end cover 2 and the distribution housing 6 and the three are detachably connected, the vane shaft 8 is penetrated in the inner cavity of the motor housing 3 and The two contact and seal, one end of the vane shaft 8 is detachably connected with the distribution plate 1, and the other end of the vane shaft 8 is supported and rotated by the bearing 15 installed on the beari...

specific Embodiment approach 2

[0024] Specific implementation mode two: combinationfigure 1 To illustrate this embodiment, the hydraulic transformer in this embodiment further includes a first screw 12 , and the motor casing 3 , the end cover 2 , the distribution casing 6 and the casing 32 are detachably connected by the first screw 12 . With such arrangement, the installation and disassembly are convenient, and the use is convenient. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the hydraulic transformer in this embodiment further includes a second screw 10 , and the bearing cover 7 is detachably connected to the distribution housing 6 through the second screw 10 . With such arrangement, the installation and disassembly are convenient, and the use is convenient. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com