Noise transmission route testing method for railway vehicle

A test method and technology of propagation path, applied in the field of rail transit, can solve the difficulty of wheel-rail noise test of near-field noise on the surface of the car body, cannot reflect the noise source characteristics of rail vehicles, the effect of vibration reduction and noise reduction, and increase the difficulty of identification, etc. problems, to achieve the effect of saving test time, fast switching, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

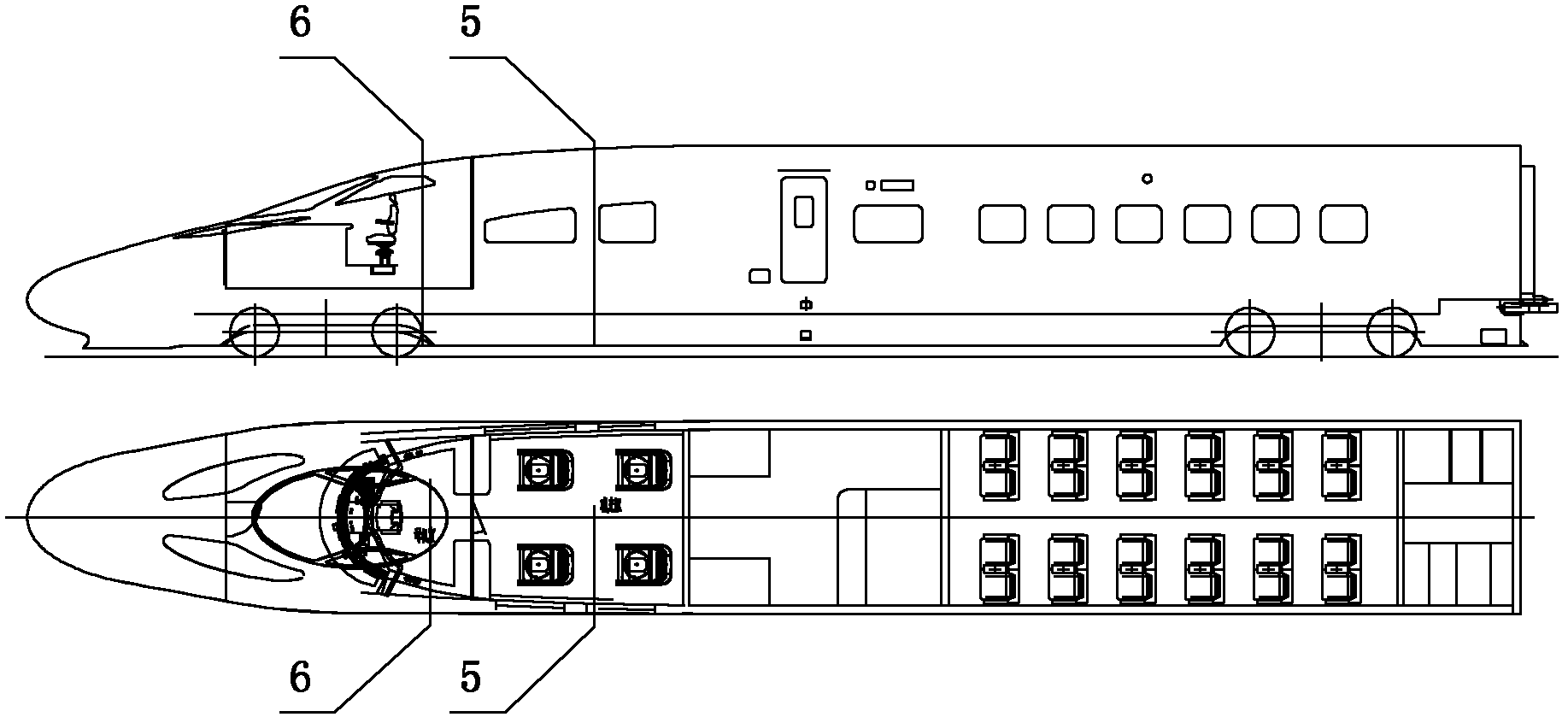

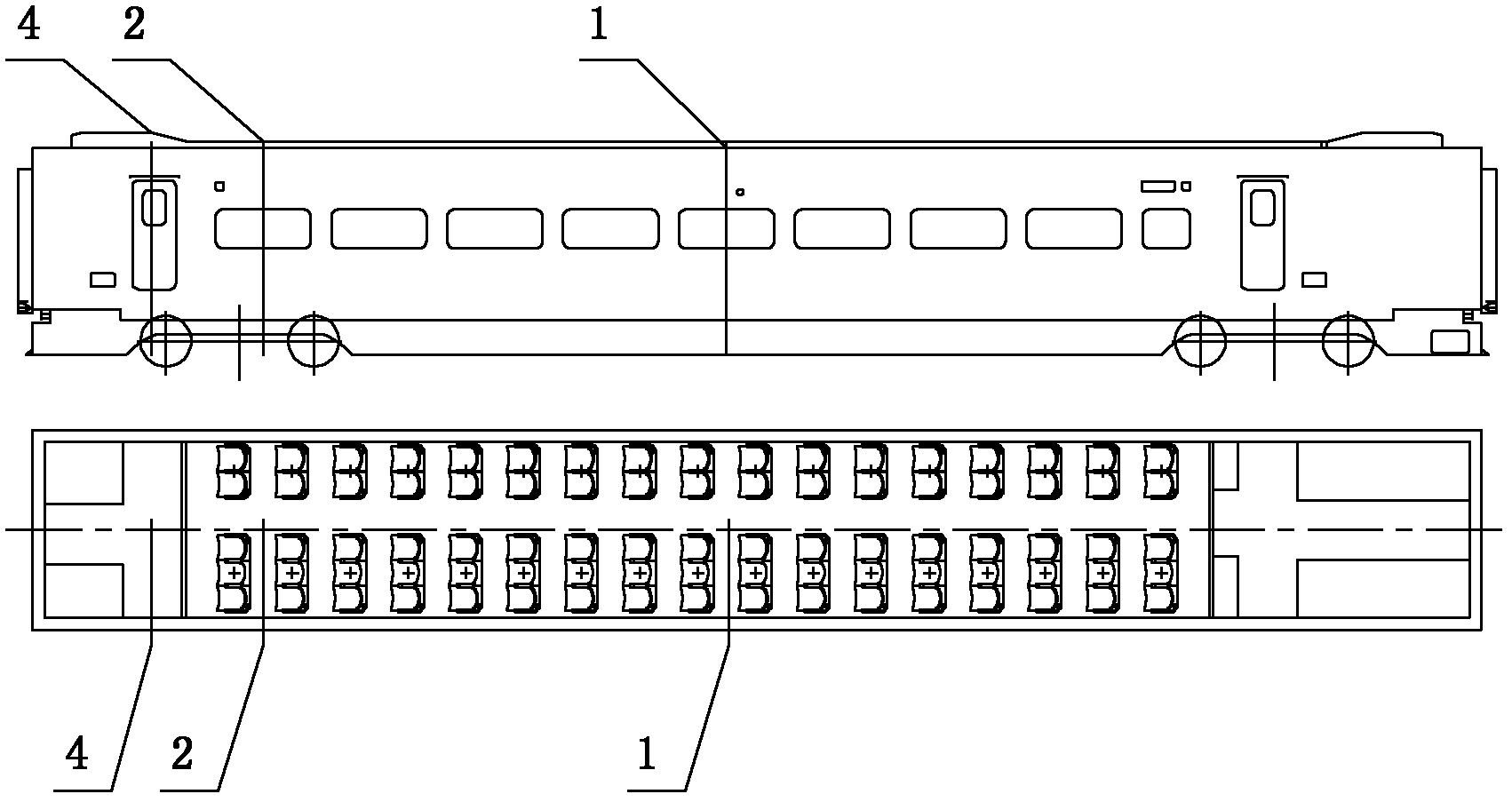

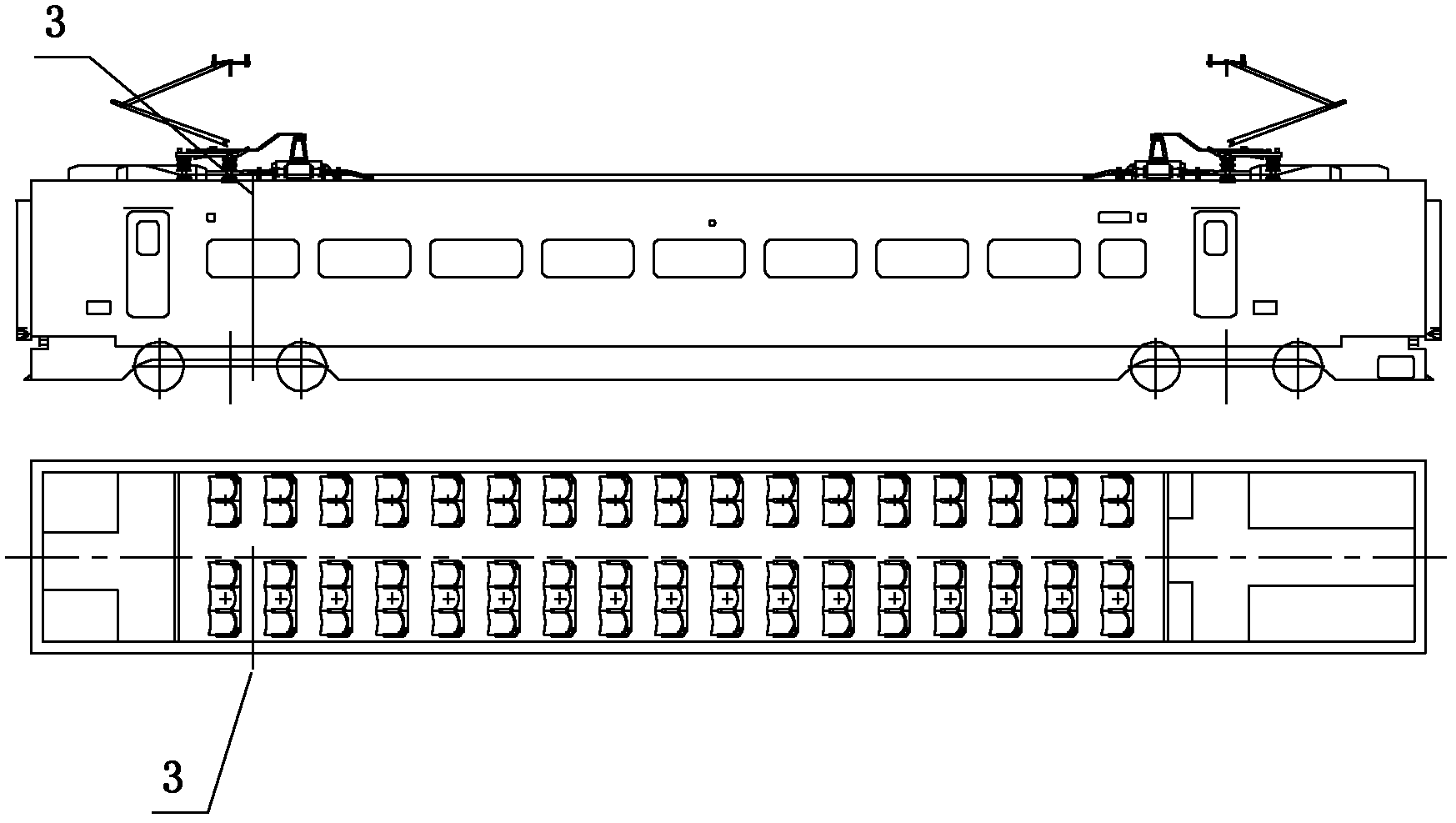

[0033] Example 1, such as Figure 1 to Figure 3 As shown, the rail vehicle noise propagation path test method specifically divides the middle section of the passenger compartment 1, the end section 2 of the passenger compartment, the pantograph area section 3, the passing platform section 4, and the sightseeing area according to the car body structure and functional divisions. Section 5 and cab section 6.

[0034] The above six test sections can basically reflect the distribution characteristics of rail vehicle noise. According to the plane layout of the vehicle, if there are special models such as a first-class car and a VIP car, and the structure of the vehicle changes greatly, the test section can be added to the corresponding part of the car. If time permits, adding a test section between the middle section of the passenger compartment and the end section of the passenger compartment can further improve the accuracy of the analysis.

[0035] Such as Figure 4 As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com