Method for detecting average crystal grain size of weld seam by utilizing weld seam characteristic guide waves

A technology of average grain size and weld characteristics, applied in the field of non-destructive testing, to achieve the effect of high efficiency, large detection range, flexible and adjustable detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

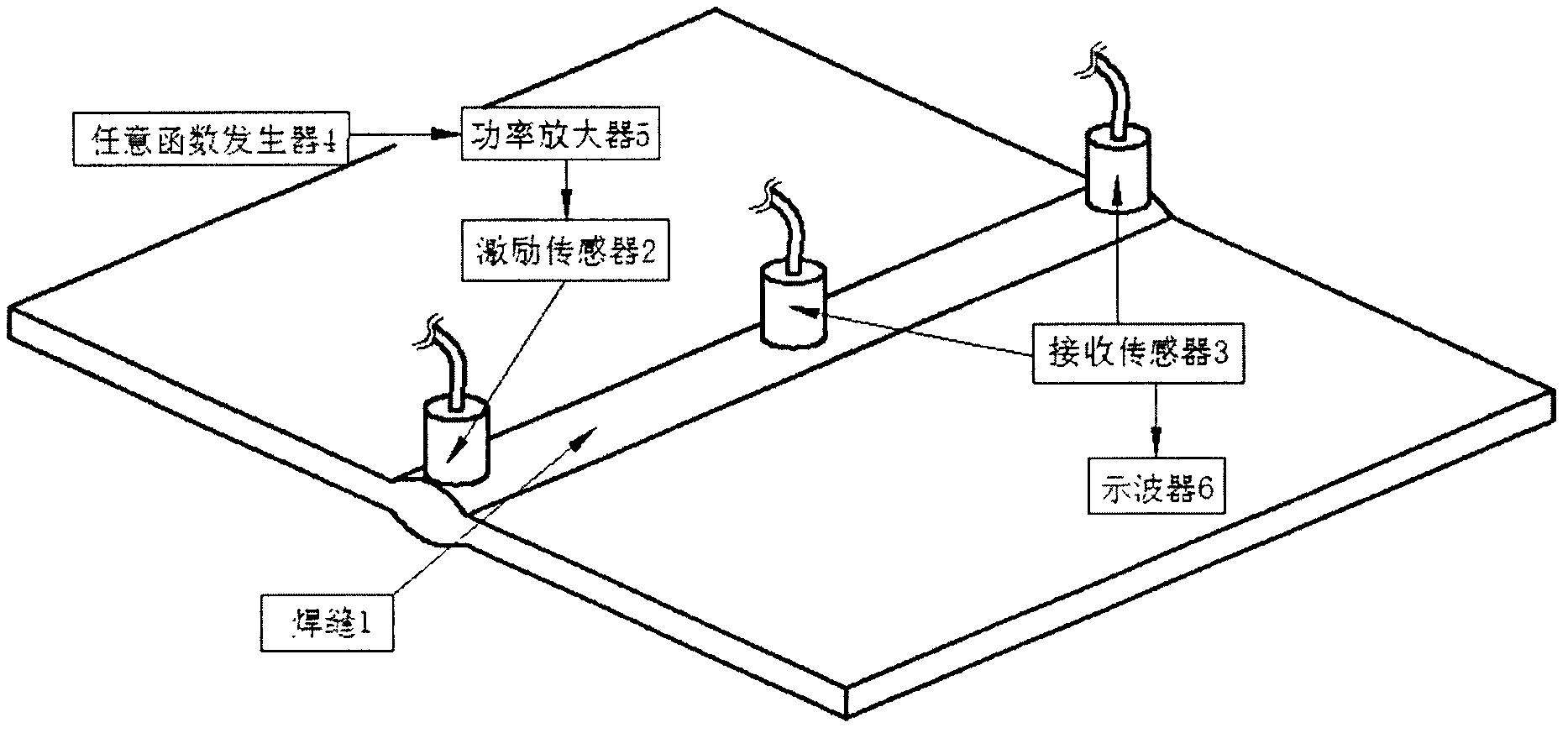

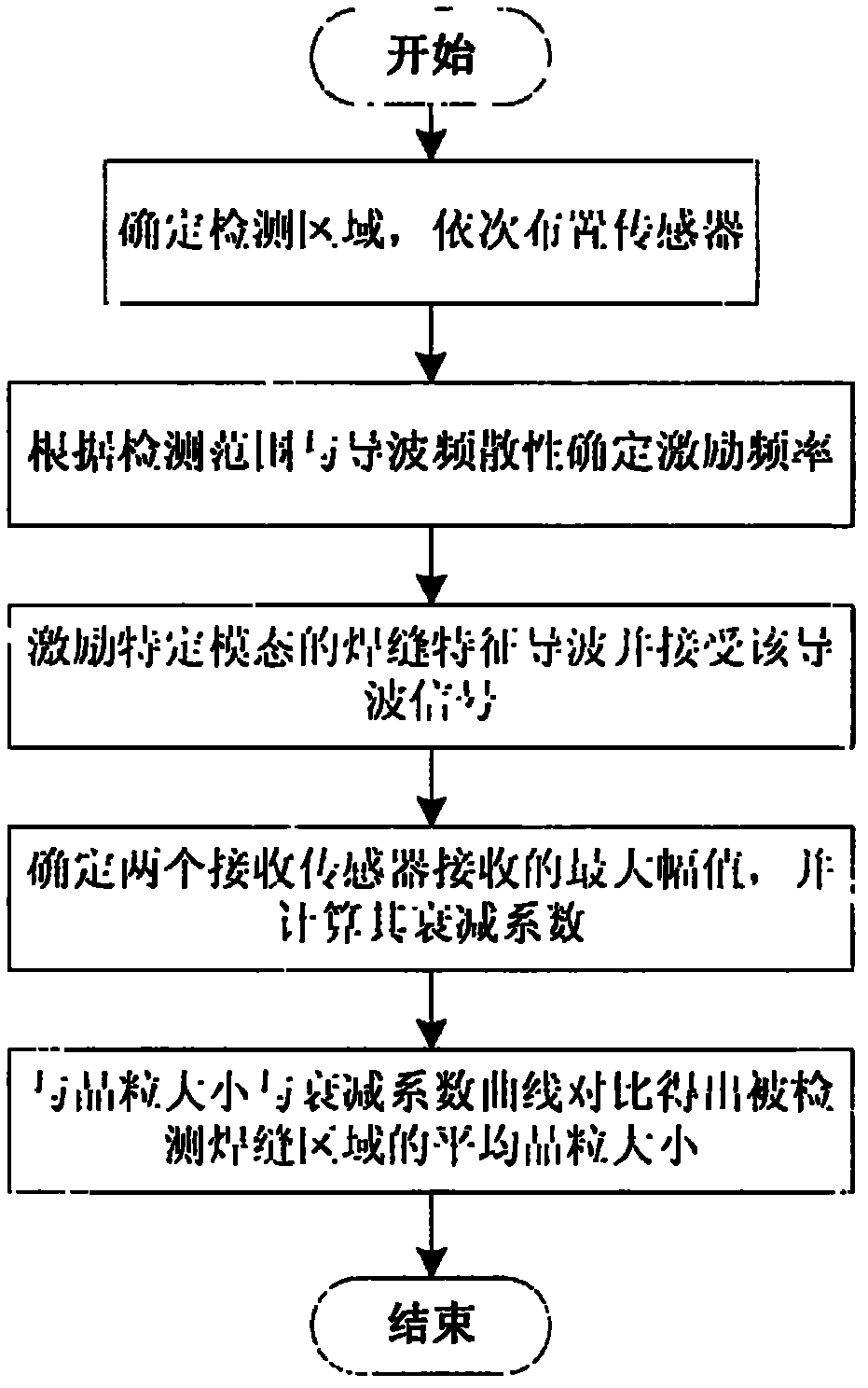

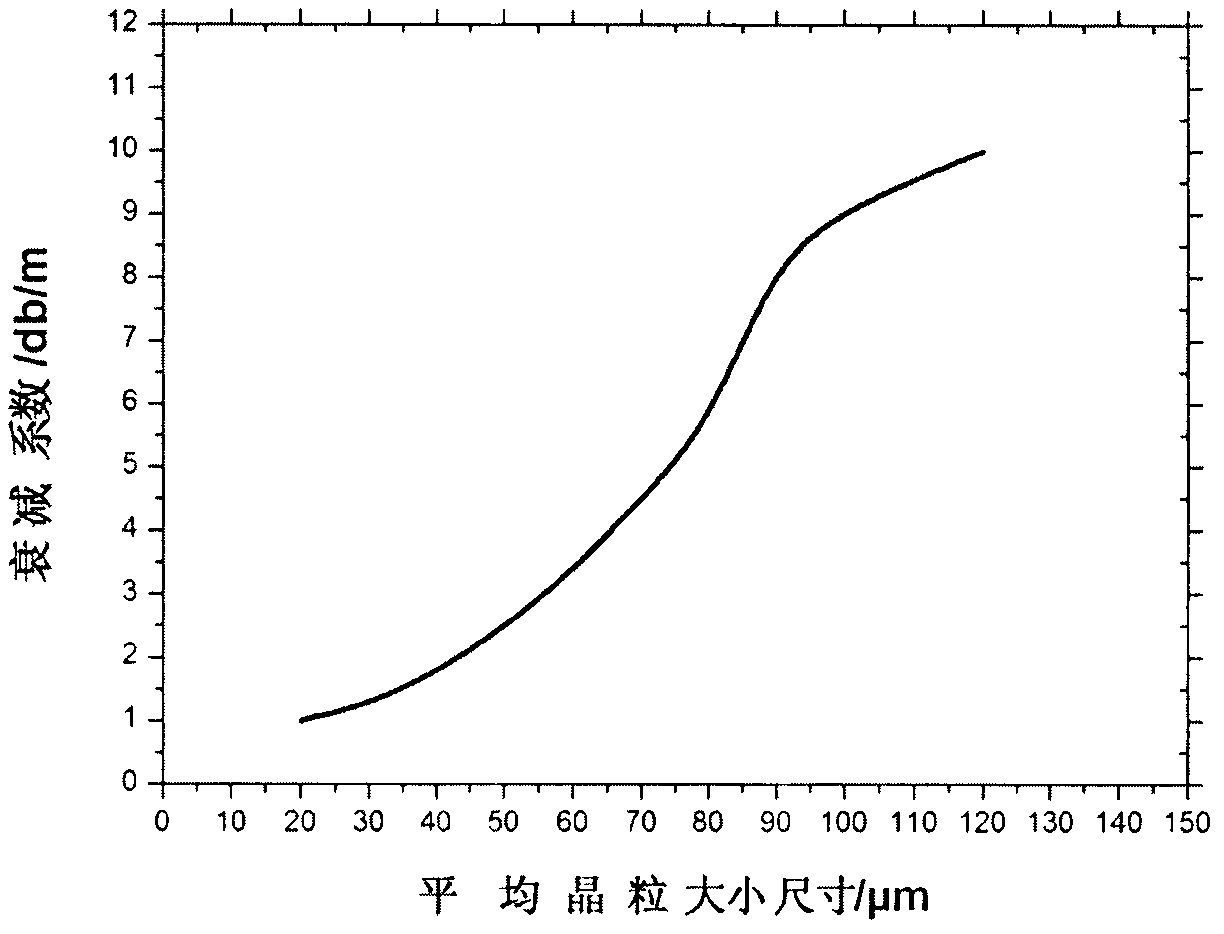

[0023] In order to deepen the understanding of the present invention, the following specific embodiments and appendix figure 1 , figure 2 with image 3 The method for detecting the average grain size of the weld seam proposed by the present invention is further detailed. The examples cited are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

[0024] Such as figure 1 , figure 2 with image 3 As shown, the butt weld is 500mm long, and the weld is formed by butting two 500mm*700mm*6mm carbon steel steel plates, and the base material is Q235. Guided wave detection method for the weld characteristics of the average grain size of the weld as follows:

[0025] 1) Choose a suitable detection position, and arrange three ultrasonic shear wave probes in sequence along the direction of the weld (1): ultrasonic shear wave probe 1, ultrasonic shear wave probe 2, and ultrasonic shear wave probe 3. The probe is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com