Ways to avoid sharp metal corners

A sharp corner and metal technology, applied in the field of avoiding metal sharp corners, to achieve the effect of no sharp corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

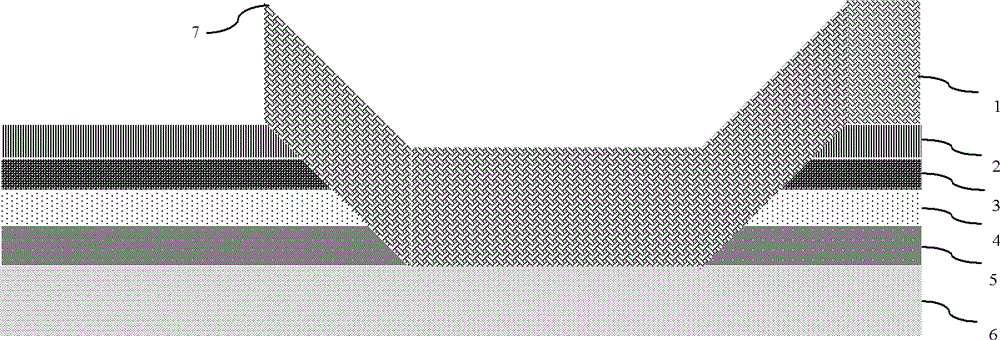

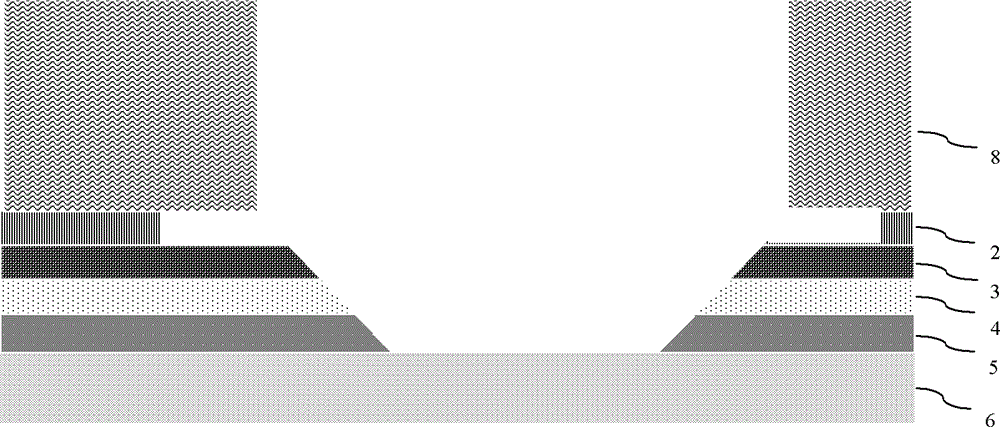

[0037] The method for avoiding metal sharp corners in the preparation of insulated gate bipolar transistors of the present invention comprises the steps of:

[0038] (1) grow several layers of oxide films on the silicon substrate 6, the specific steps are as follows:

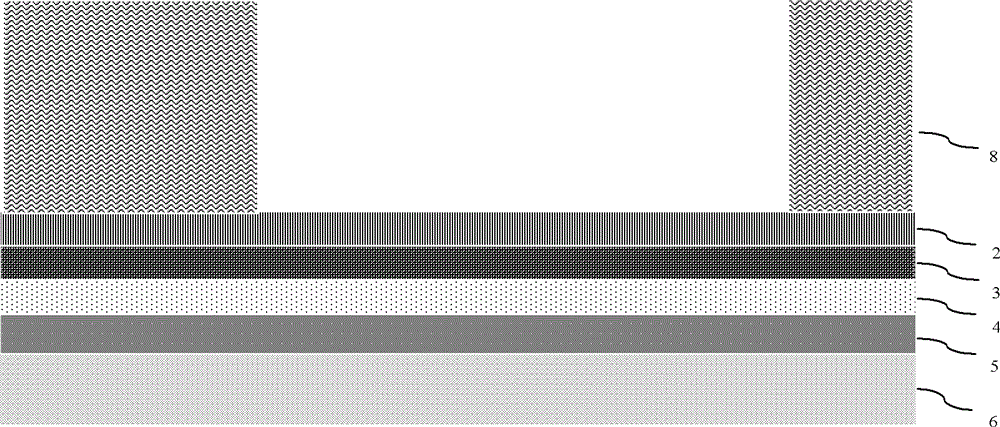

[0039] like figure 2 As shown, different doping concentrations, film forming temperatures and film forming methods are used on the silicon substrate 6 to grow the following oxide films:

[0040] ①Use subatmospheric pressure chemical vapor deposition first, and deposit a layer of subatmospheric phosphorus doped silicon oxide film 5 (first oxide film) grown at 480°C with a doping concentration of 3% at 1 micron under a pressure of 200 Torr. );

[0041] ② On the basis of step ①, use high-density plasma chemical vapor deposition to grow a layer of 0.7 micron high-density plasma-enhanced phosphorus-doped silicon oxide grown at 380°C with a doping concentration of 4% under a pressure of 10 mTorr Film 4 (first oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com