Disc motor

A disc motor and armature technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, magnetic circuit rotating parts, etc., can solve low production efficiency and difficulties in armature winding processing and manufacturing , complex production process and other issues, to achieve the effect of small installation volume, stable torque output and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

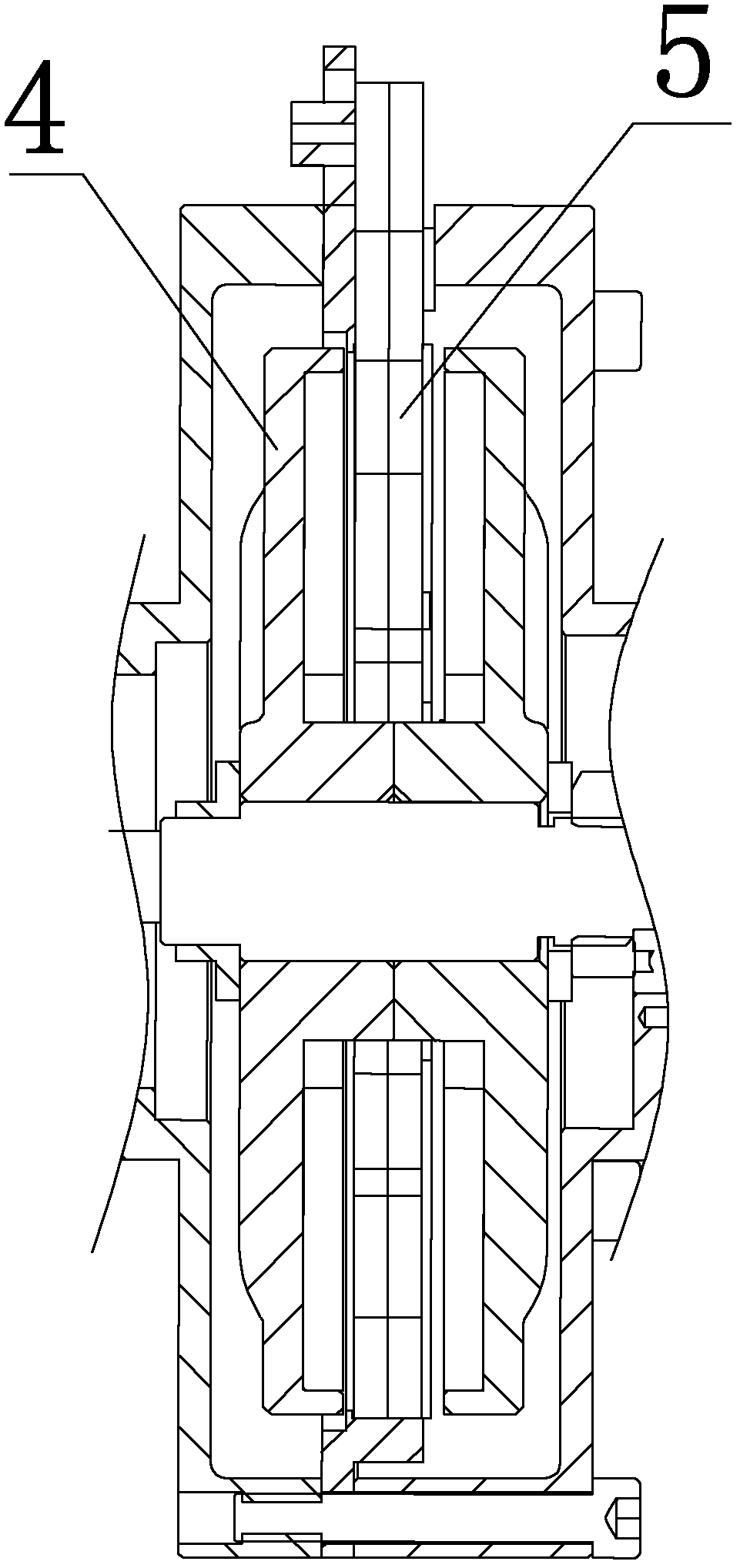

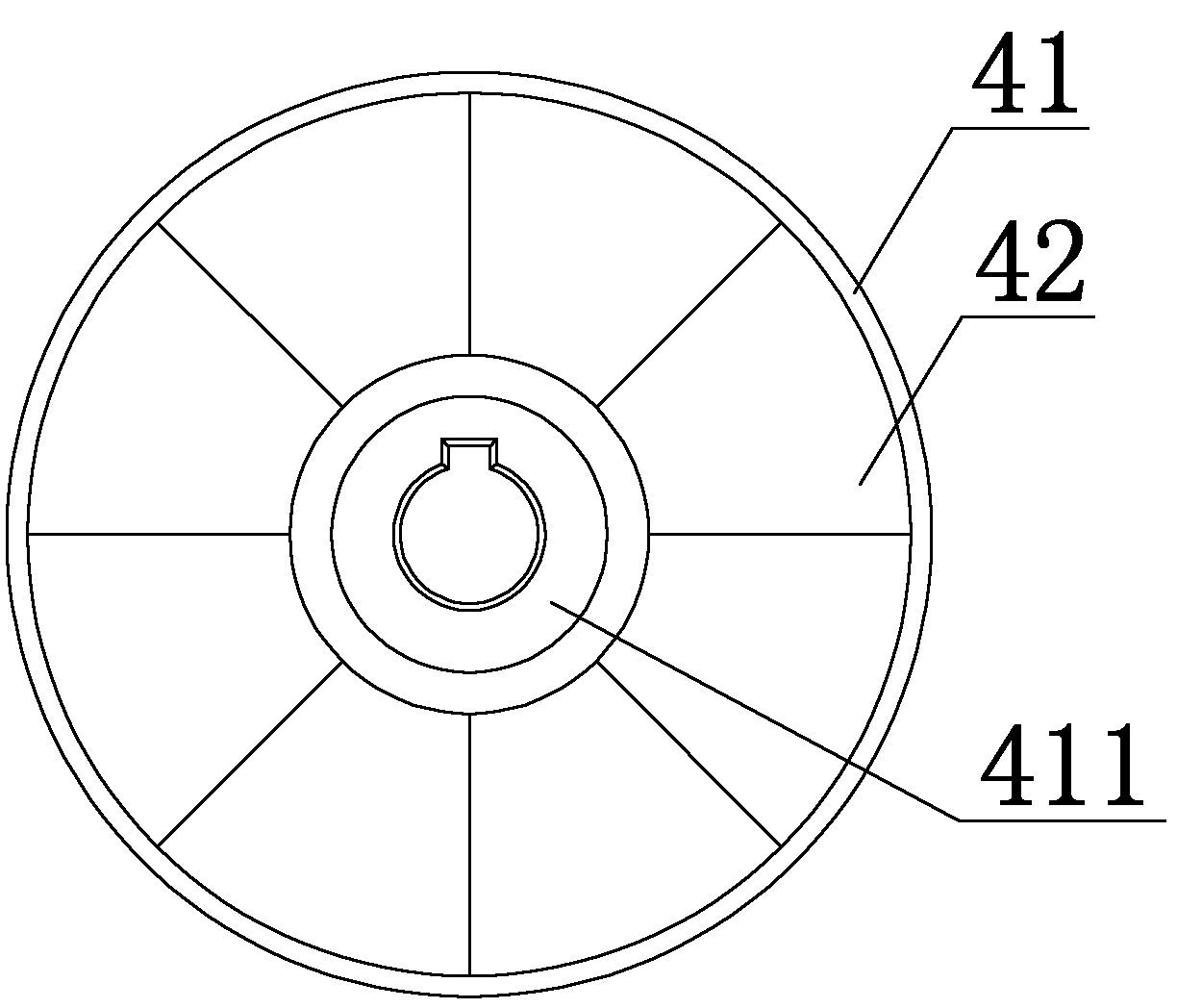

[0015] Such as figure 1 As shown, a disc motor has an armature 5 and a symmetrically installed magnetic steel assembly assembly 4, such as figure 2 As shown, the magnetic steel assembly assembly 4 is composed of a magnetic steel mounting plate 41 and a fan-shaped magnetic steel 42 surrounding a circle. The magnetic steel mounting plate 41 has a motor magnetic steel plate 411 with a motor mounting shaft hole in the center. The magnetic steel mounting plate 41 and the motor magnetic steel disc 411 are integrally structured. This one-piece structure facilitates magnetic shielding.

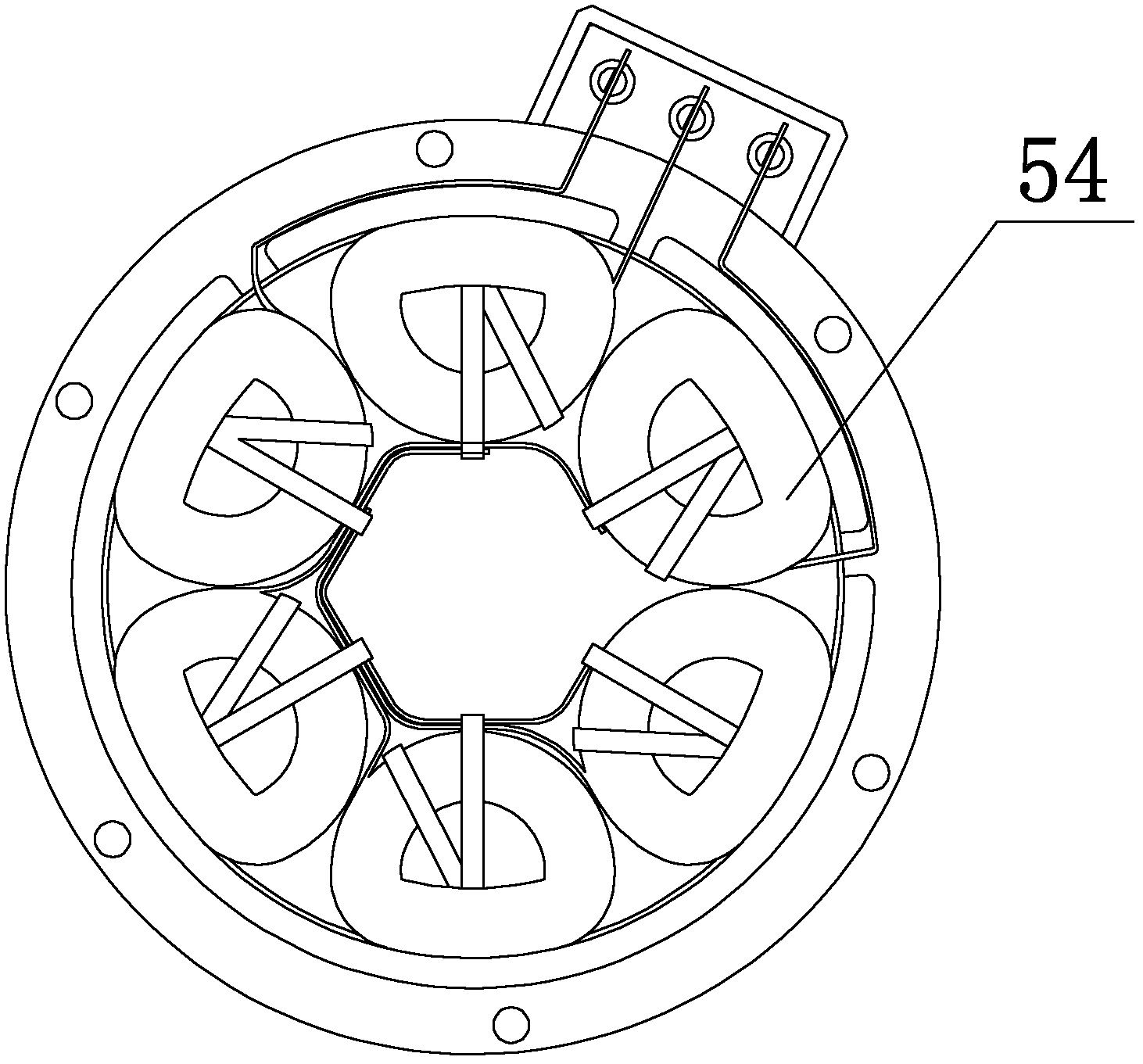

[0016] Such as figure 1 As shown, the armature 5 is installed between the symmetrically install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com