A low-speed high-torque permanent magnet brushless motor

A permanent magnet brushless motor, low-speed high-torque technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of power loss, speed drop, high power loss, etc., to improve torque ripple, reduce no-load loss, large The effect of winding space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

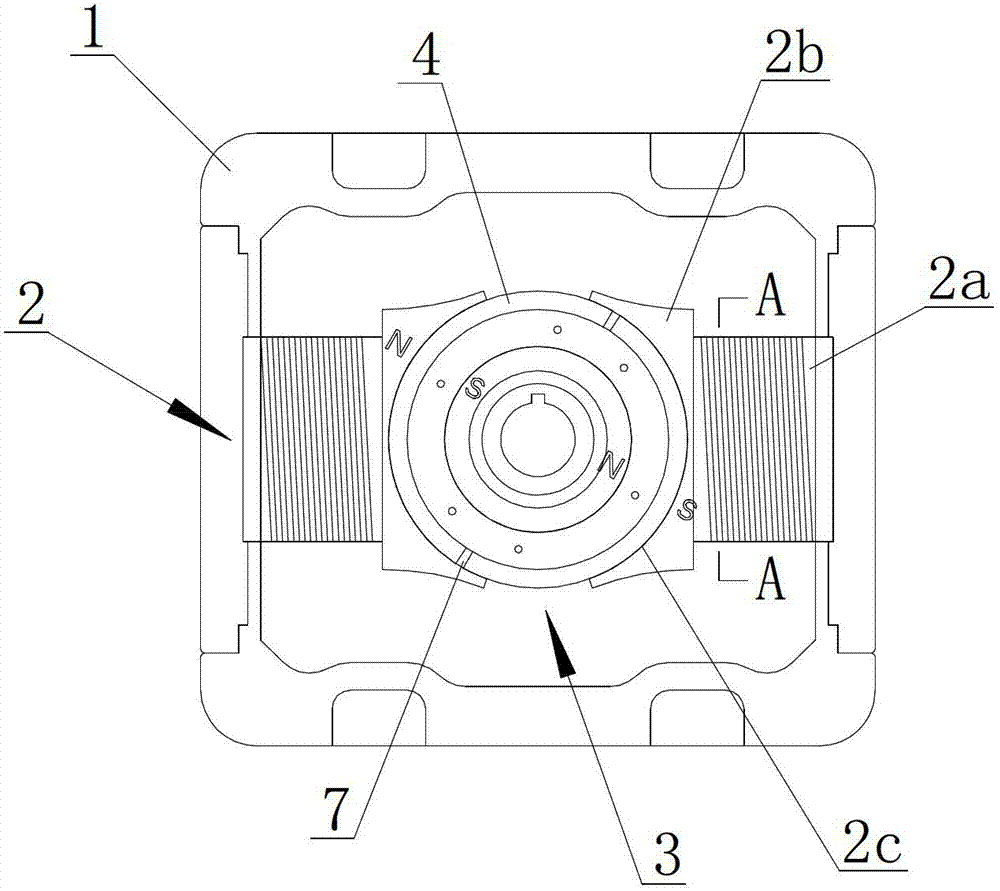

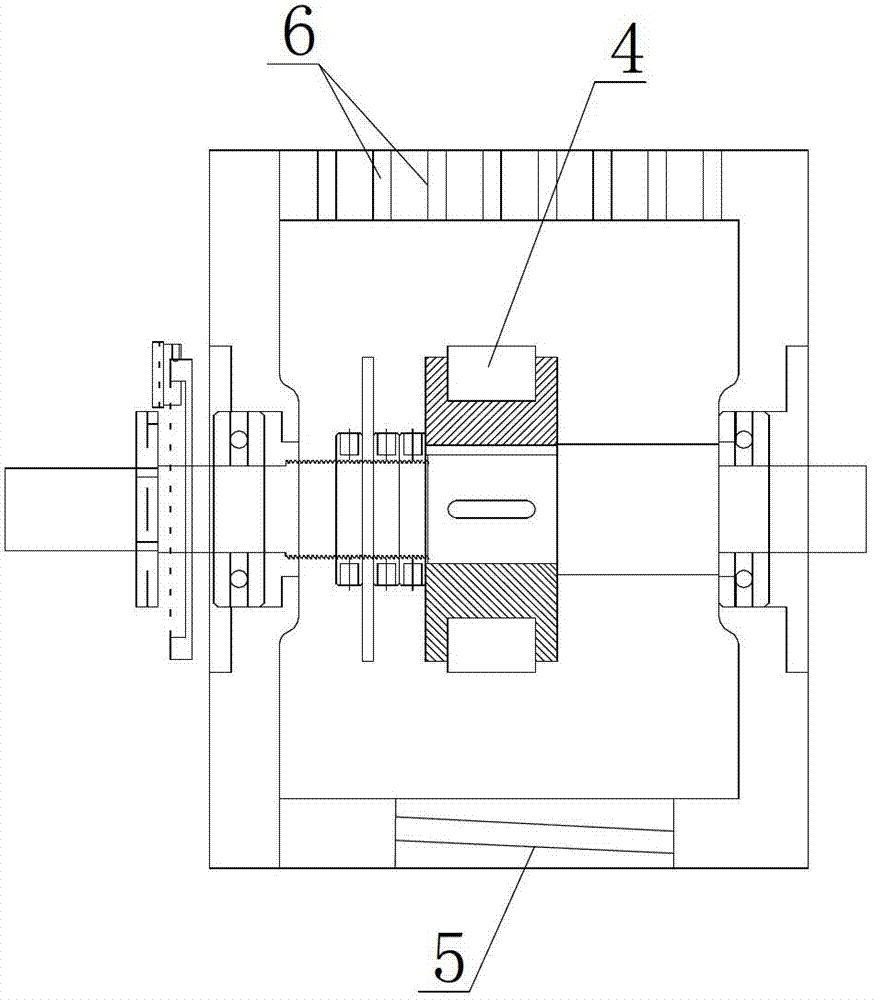

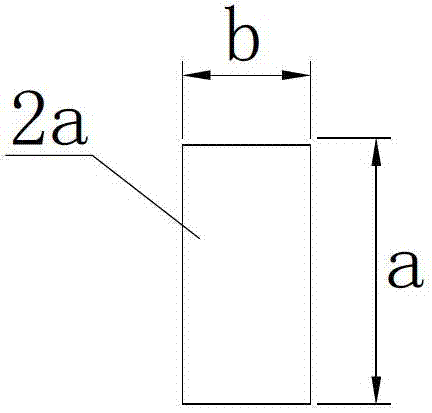

[0017] refer to Figure 1 to Figure 3 As shown, a low-speed high-torque permanent magnet brushless motor of the present invention includes a casing 1, and two stator electromagnets 2 corresponding to each other are provided along the circumference of the casing 1, and the stator electromagnet 2 is formed by a coil base 2a Composed of an extension seat 2b connected to the coil seat 2a, the end surface of the extension seat 2b away from the coil seat 2a is an arc-shaped surface 2c, and the arc of the arc-shaped surface 2c is 130-160°, preferably 140-145° , a winding space is formed in the casing 1 on both sides of the coil seat 2a, so that the fuselage part has a larger winding space under the same conditions; at the same time, the extension seats 2b on both sides of the arc surface 2c are triangular , so that the magnetic field intensity changes on both sides are different. This structure can improve the torque ripple and make the rotation more balanced; there is a rotor 3 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com