Self-adaptation variable volume refrigeration system

A refrigeration system and variable capacity technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of narrow adjustment range and poor adaptability, and achieve the effect of high control accuracy and wide adjustment application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

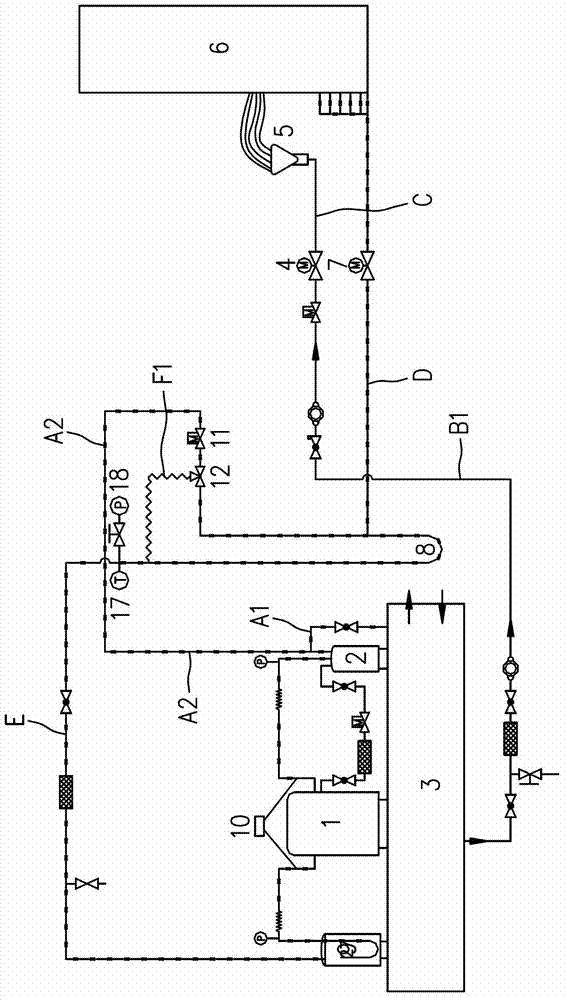

Embodiment 1

[0049] Such as figure 1 As shown, an adaptive variable capacity refrigeration system, the refrigeration system includes a compressor 1, a condenser 3 and an evaporator 6, the high-pressure gas discharged from the outlet of the compressor 1 first enters the oil separator 2, and is processed by the oil separator 2 The final high-pressure gas enters the first high-pressure gas pipeline A1 and the second high-pressure gas pipeline A2 respectively; the oil separator 2 is connected to the compressor 1 through an oil return pipeline.

[0050] The outlet of the first high-pressure gas pipeline A1 is connected to the inlet of the condenser 3, that is, the water-cooled condenser, and the high-pressure liquid discharged from the outlet of the condenser 3 is connected to the inlet of the electronic expansion valve 4 through the high-pressure liquid pipeline B1. The low-pressure liquid discharged from the outlet of the electronic expansion valve 4 is connected to the inlet of the evaporato...

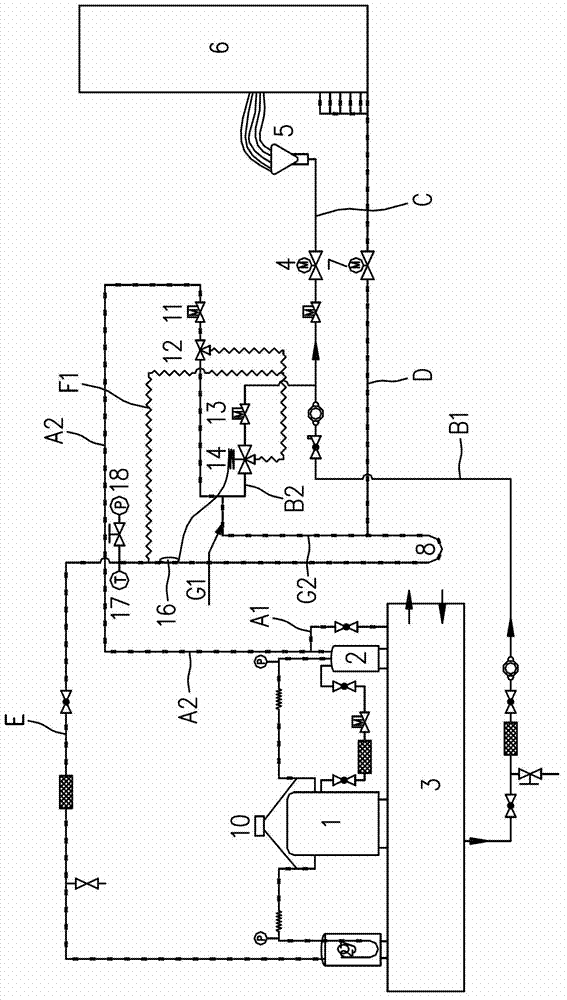

Embodiment 2

[0056] Embodiment 2 adds a liquid bypass pipeline B2 for suction cooling on the basis of the pipeline structure of Embodiment 1. The inlet side of the liquid bypass pipeline B2 is connected to the high-pressure liquid pipeline B1, and the liquid bypass pipeline The outlet side of the pipeline B2 communicates with the second high-pressure gas pipeline A2; the liquid bypass pipeline B2 is provided with a suction cooling solenoid valve 13 and a suction cooling thermal expansion valve 14 in series along the liquid flow direction ; The air suction cooling thermal expansion valve 14 and the first hot gas bypass control valve 12 share the pressure taking pipeline F1, and the temperature sensing package 16 of the air suction cooling thermal expansion valve 14 is arranged on the air return pipe on the outlet side of the oil return bend 8 on road E.

[0057] The liquid bypass pipeline B2 intersects with the second high-pressure gas pipeline A2 and then connects with the horizontal confl...

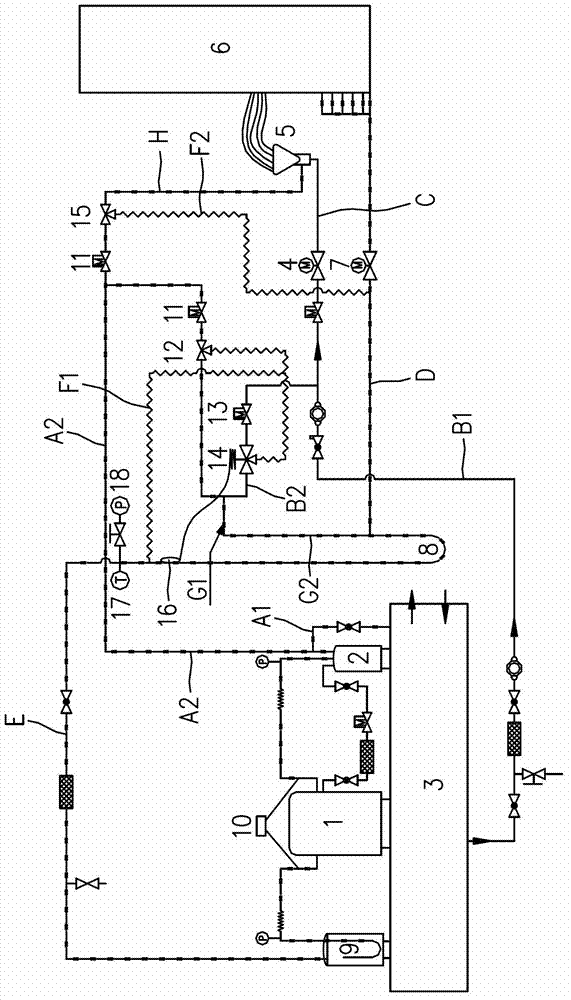

Embodiment 3

[0060] Embodiment 3 adds a gas bypass pipeline H leading to the separator 5 on the basis of the pipeline structure of Embodiment 2, and the gas bypass pipeline H is connected to the second high-pressure gas pipeline A2, and the A solenoid valve 11 and a second hot gas bypass control valve 15 are arranged in series on the gas bypass pipeline H along the direction of gas flow. 7 The low-pressure gas pipeline D on the outlet side is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com