Interlayer-free diffusion connecting method of hard alloy and steel

A cemented carbide and diffusion bonding technology, which is applied in the field of welding, can solve the problems of external pressure and intermediate layer, and achieve the effects of slow cooling speed, favorable joint formation and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

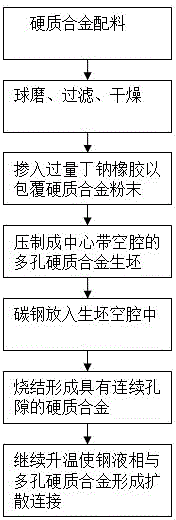

Method used

Image

Examples

example 1

[0016] Example 1: The particle size of Co in the raw material powder for preparing cemented carbide is 1.1 μm, the particle size of Ni is 1.3 μm, the particle size of Fe is 2.4 μm, and the particle size of WC is 2.0 μm; the weight percentage of cemented carbide is that Co accounts for 10wt% , Ni accounts for 2wt%, Fe accounts for 3wt%, and WC is the balance. The ball milling medium of cemented carbide mixed powder is absolute ethanol, the dosage is 280ml, the ball milling speed is 70r / min, the milling time is 64h, the grinding ball is Φ8mm WC-8wt%Co cemented carbide ball, the weight ratio of ball to material The ratio is 5:1; after ball milling, the cemented carbide slurry is filtered with 400 mesh, the vacuum drying temperature is 90°C, and the vacuum degree is 1 Pa; the addition of butadiene rubber is 30 wt%, and the powder mixed with butadiene rubber is in the Dry at 85°C for 2 hours, and sieve through 100 mesh. The powder is pressed into a cemented carbide green body with...

example 2

[0017]Example 2: The particle size of Co in the raw material powder for preparing cemented carbide is 1.3 μm, the particle size of Fe is 3.0 μm, and the particle size of WC is 1.3 μm; for the margin. The ball milling medium of cemented carbide mixed powder is absolute ethanol, the dosage is 400ml, the ball milling speed is 100r / min, the milling time is 64h, the grinding ball is Φ6mm WC-8wt%Co cemented carbide ball, the weight ratio of ball to material 10:1; after ball milling, the cemented carbide slurry was filtered through 400 mesh, the vacuum drying temperature was 100°C, and the vacuum degree was 2 Pa; the addition of butadiene rubber was 40 wt%, and the powder mixed with butadiene rubber was Dry at 90°C for 1 hour, and sieve through 100 mesh. The powder is pressed into a cemented carbide green body with a cavity in the center, and the porosity of the green body is 60% by adjusting the filling weight of the cemented carbide powder coated with butadiene rubber, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com