A two-way self-centering automatic taper machine tool

A self-centering and self-centering fixture technology, which is applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problems of high labor intensity, low production efficiency and complicated operation, and achieve The effect of simplifying the processing flow, improving production efficiency and simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

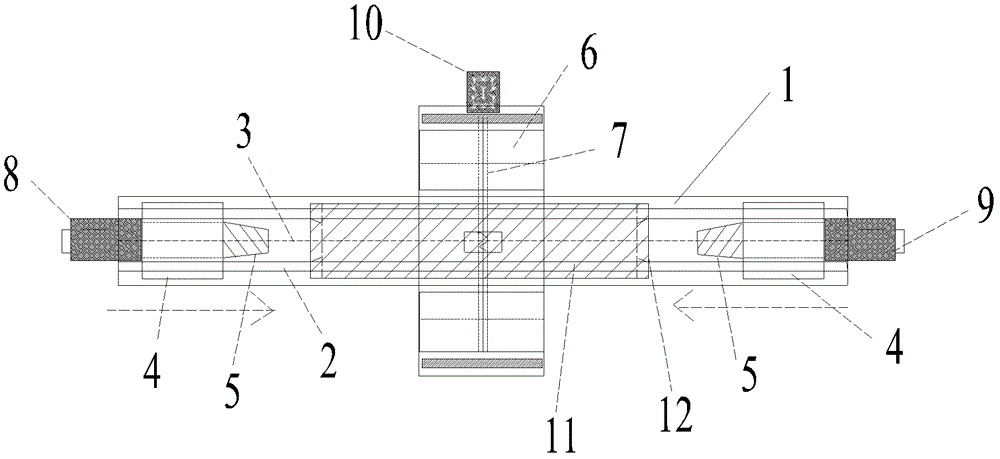

[0020] Such as figure 1 As shown, a two-way self-centering automatic taper machine tool includes a machine tool single-coordinate control system, a machine bed 1, a machine tool Z-direction linear track 2, two movable rotating headstocks 4, and two drilling and reaming tools 5. Self-centering fixture 6, machine bed 1 can be customized according to workpiece size specifications, machine tool Z-direction linear track 2 is installed on machine tool bed 1, and two movable rotating headstocks 4 are respectively arranged on machine tool Z-direction linear track At both ends of the rail 2, two drilling and reaming tools 5 are set up on the front ends of the two movable rotating head frames 4 respectively and are arranged oppositely. The drilling and reaming tools are tapered drilling and reaming tools, and the self-centering fixture 6 It is arranged on the Z-direction linear track 2 of the machine tool and is located in the middle of two movable rotating headstocks 4. The two movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com