On-line measuring device for diameter of wind power bearing raceway

A technology of bearing raceway and measuring device, which is applied in the direction of grinding machine tool components, workpiece feed movement control, metal processing equipment, etc., to achieve the effects of reducing inventory, ensuring quality stability, and improving interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

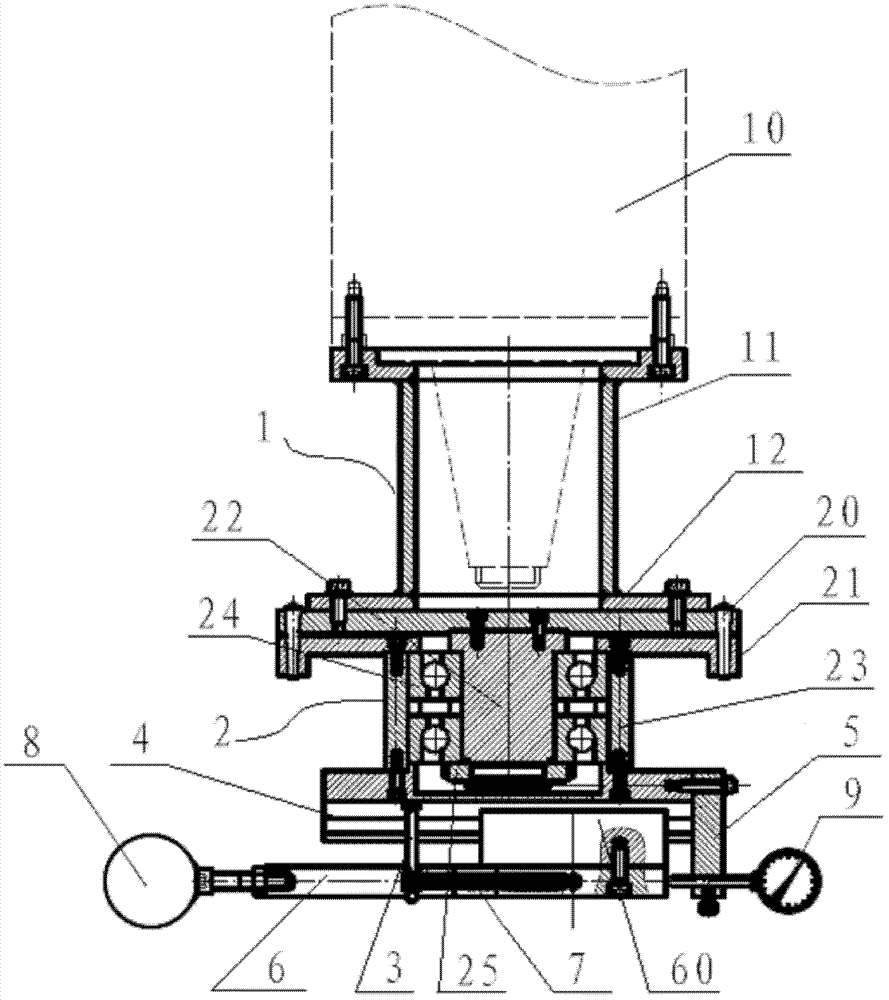

[0017] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

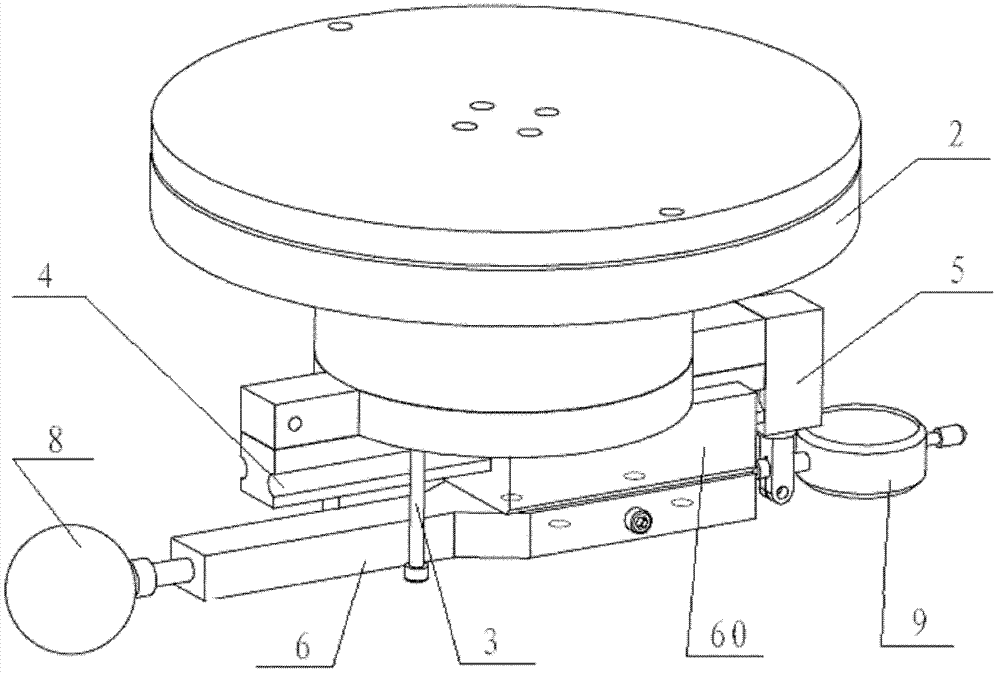

[0018] see figure 1 with figure 2 , an on-line measuring device for the raceway diameter of a wind power bearing of the present invention is installed on a large vertical numerically controlled grinding machine. A hanger 5, a measuring rod 6, a pair of extension springs 7, a measuring steel ball 8 and a dial indicator 9, wherein:

[0019] The connector 1 includes a set of sleeve 11 outside the grinding machine spindle 10 and a lower end flange 12 connected to the lower end surface of the sleeve 11; two conical through holes are evenly distributed on the surface of the lower end flange 12;

[0020] The rotating mechanism 2 is connected to the lower end of the connector 1, and the rotating mechanism 2 includes an upper end flange 21, a mandrel 22, a rotating ring 23, two rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com