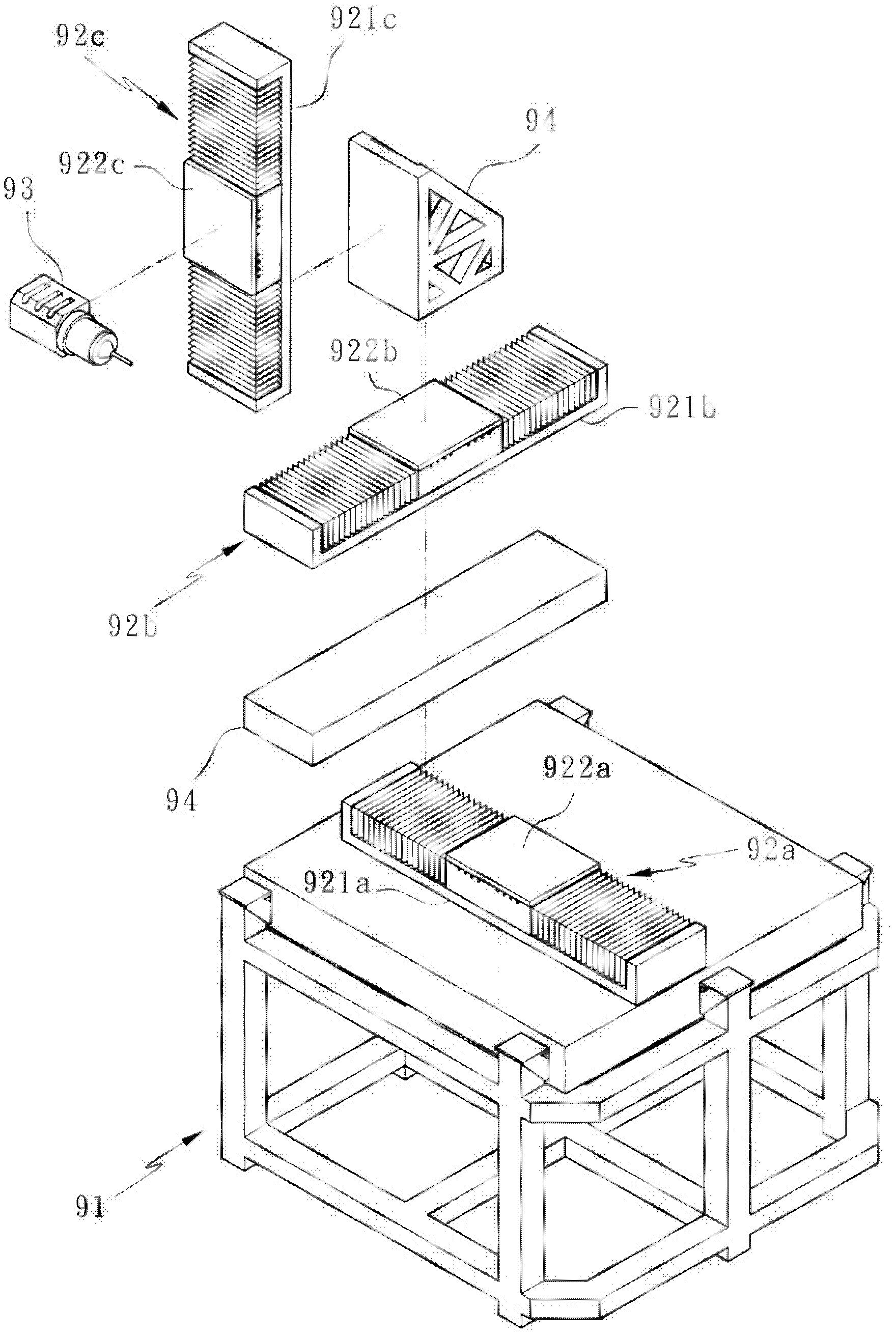

Assembling device of reconfigurable toolroom machine

A machine tool and structure technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of large operation area, difficult to maintain stability, and time-consuming manual adjustment, so as to reduce the operation area and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

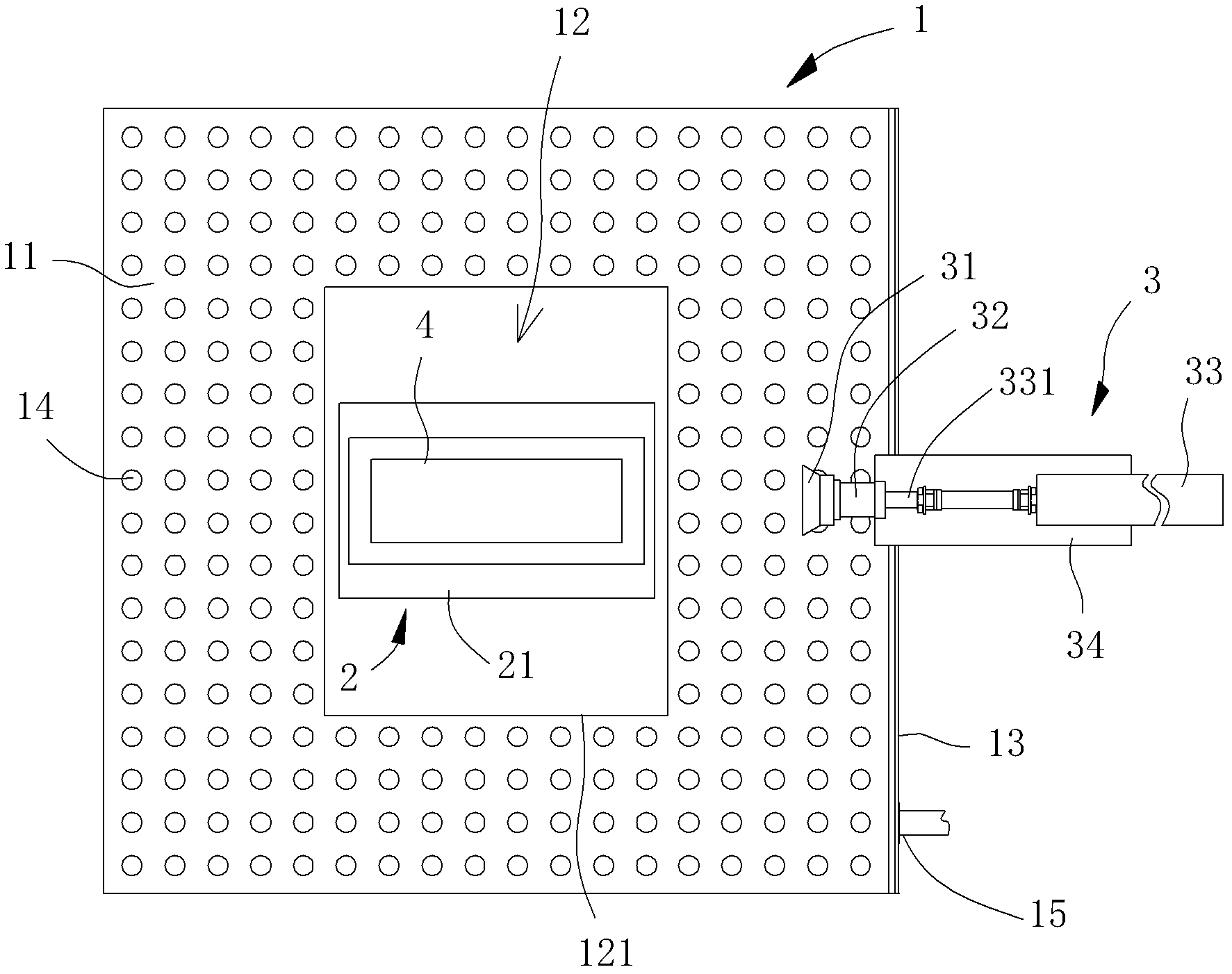

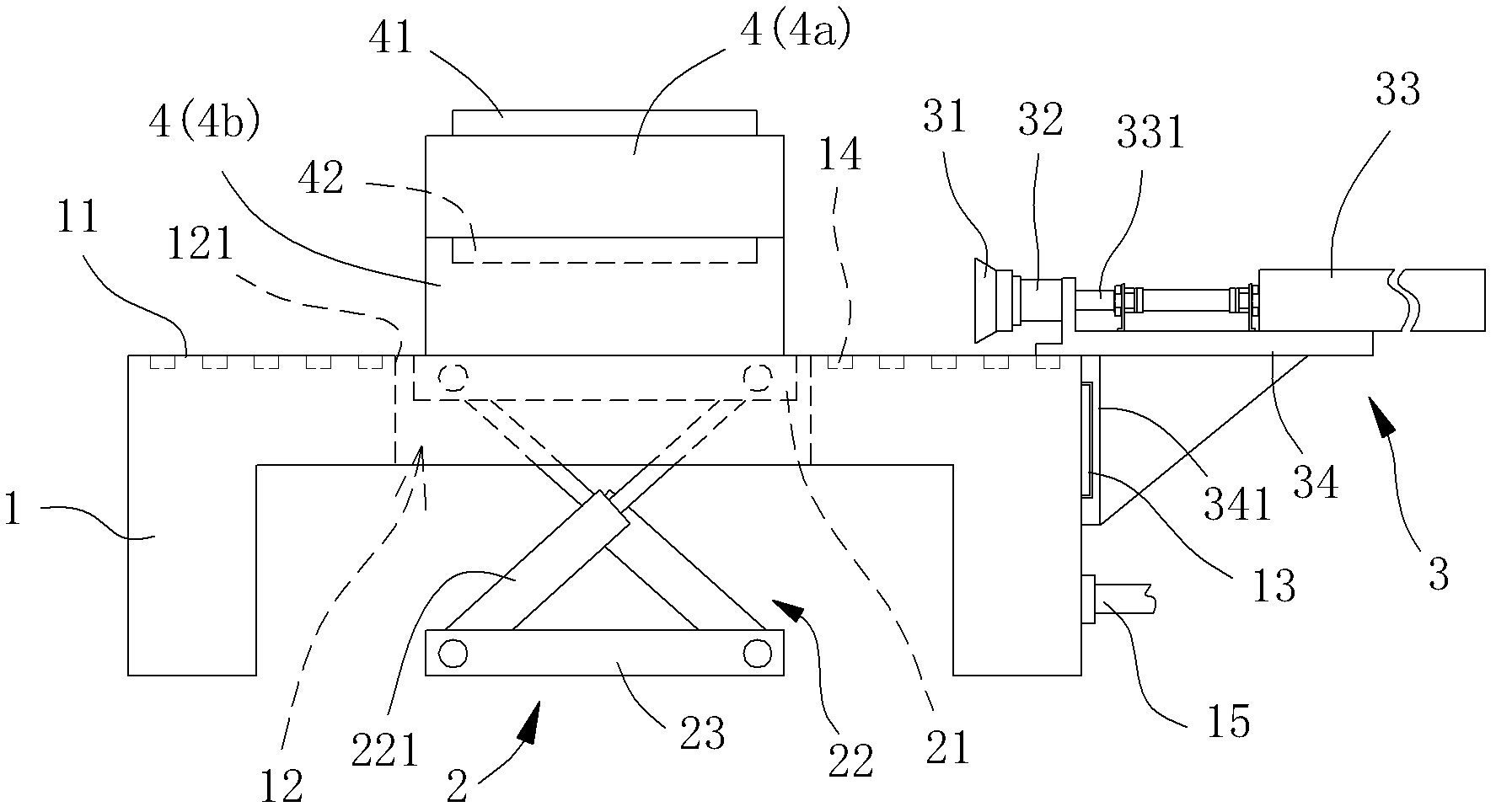

[0046] see figure 2 , image 3 , which is a preferred embodiment of the present invention, the structural device of the reconfigurable machine tool is used to disassemble or reorganize a reconfigurable machine tool, and the structural device of the reorganizable machine tool includes a bearing seat 1, a lifting module 2 and a suction module 3, the lifting module 2 can drive at least one component 4 of the reconfigurable machine tool to lift up and down, the suction module 3 can suck the component 4 carried by the lifting module 2, and lift the component 4 Move to the bearing seat 1.

[0047] Please refer to Figure 4 , the top of the bearing seat 1 forms a bearing surface 11, and the bearing surface 11 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com