Tire with color pattern and production method thereof

A technology of color patterns and production methods, applied in tire parts, tires, tire sidewalls, etc., can solve the problems of difficulty in ensuring clear edges of various colors, regular shapes, complex production processes of colored tires, and less attention. , to achieve the effect of improving appearance quality, clear color edge and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

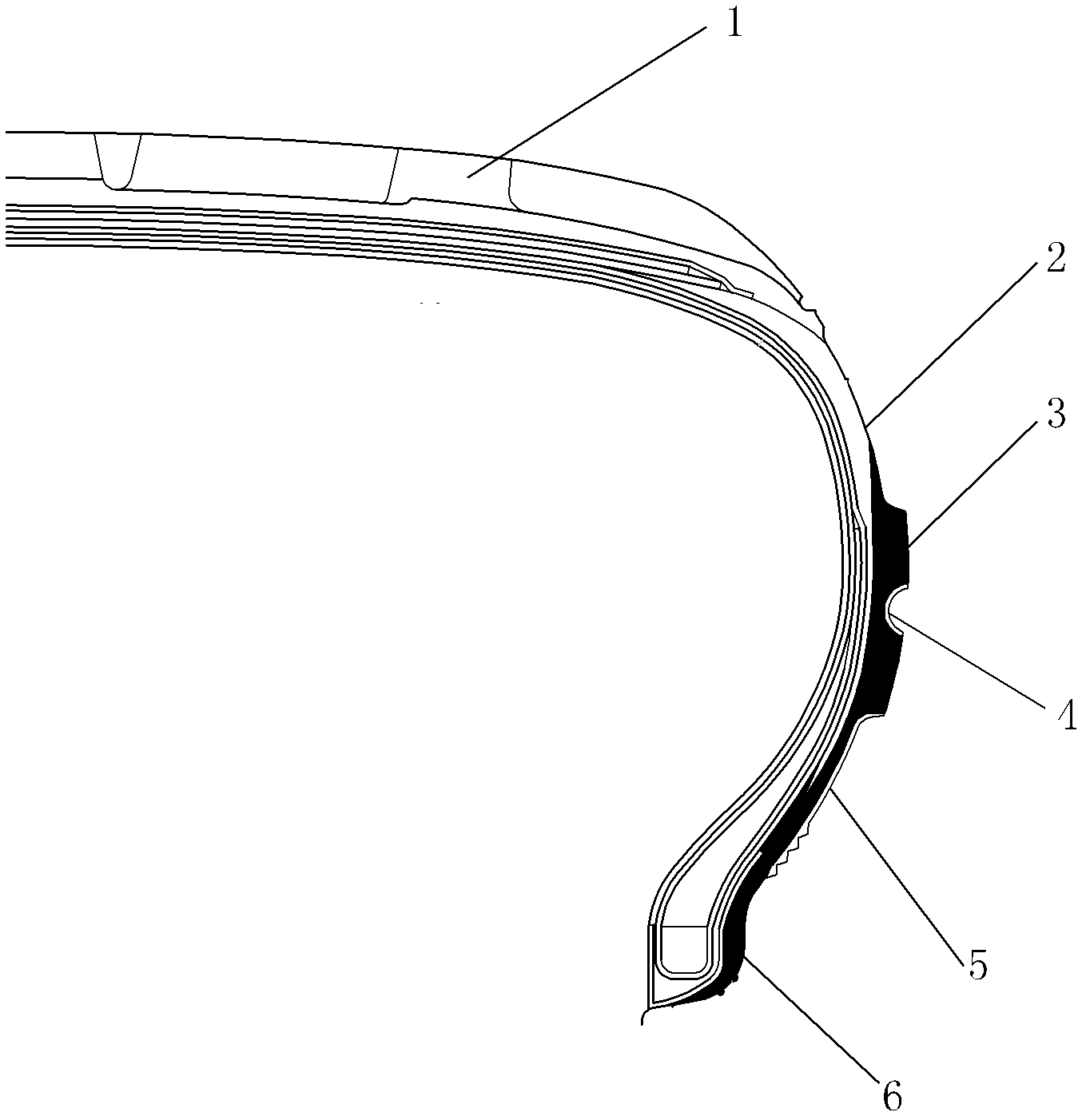

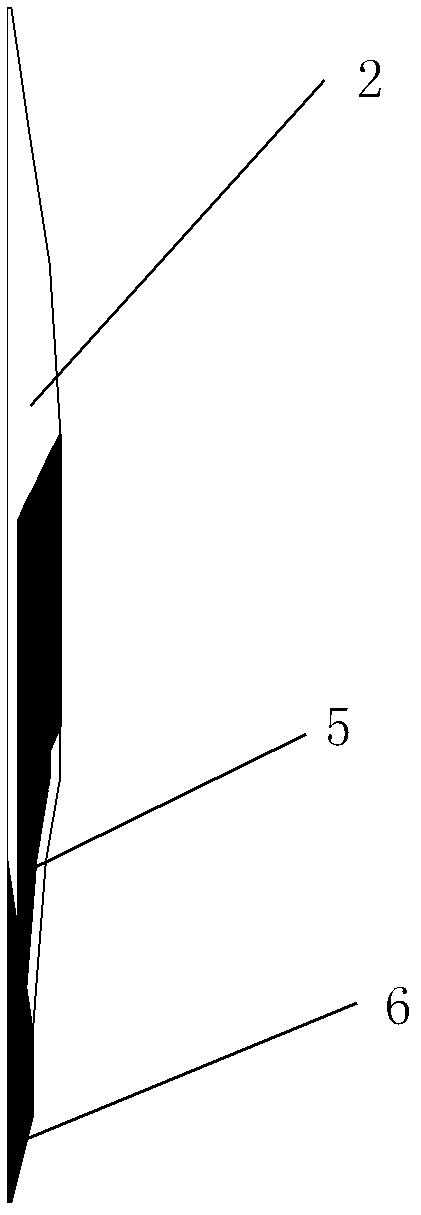

[0027] Such as figure 1 As shown, the tire of the present invention includes a tread 1 and a sidewall 2. The tire is mainly made of black rubber material, wherein the sidewall 2 is provided with a boss 3, and the boss 3 is provided with a color film 4. The color film 4 forms a colored inwardly depressed ring on the sidewall 2 in the circumferential direction. The lower part of the boss is the side wall formed by the colored rubber material 5, and a colored ring is formed along the circumferential direction under the boss. The upper end of the color rubber material 5 is flush with the lower edge of the boss 6 surface, and its lower end is positioned at the top of the spigot protective glue 6 .

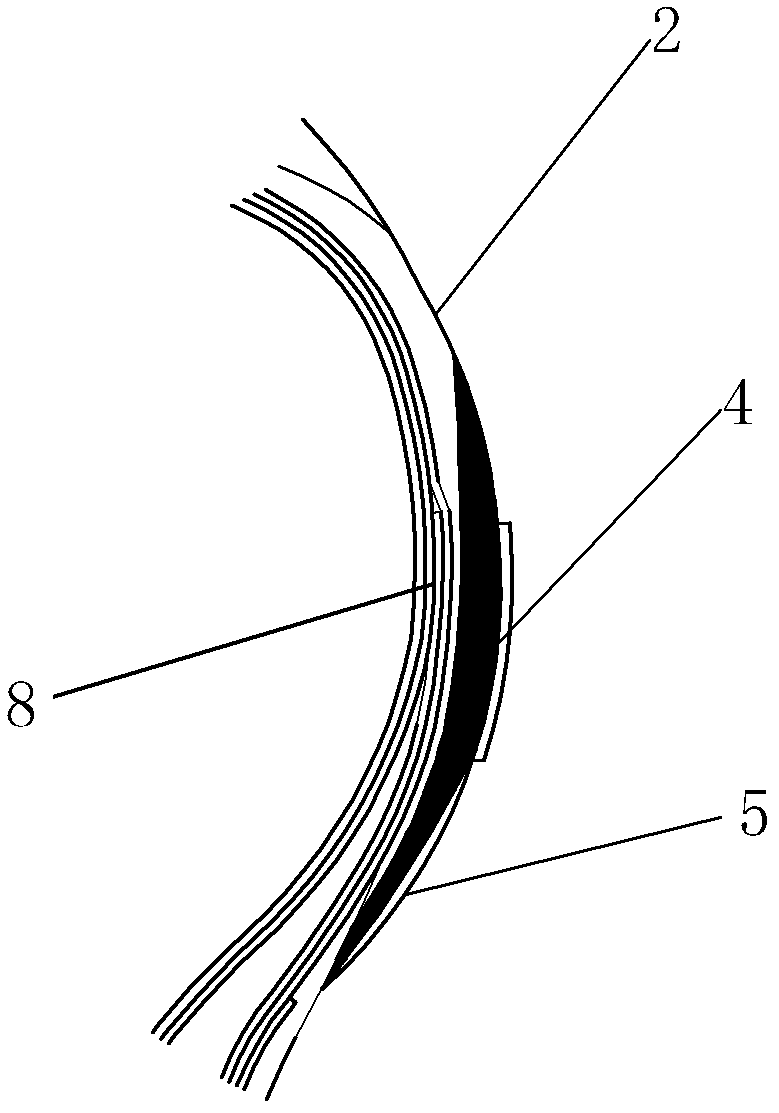

[0028] figure 1 The tire shown in is completed through the following process: the sidewall 2 is composed of black rubber material and colored rubber material 5, and the two materials are extruded through a compound extruder, figure 2 It is a cross-sectional view of the sidewall 2 af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com