Electric locomotive adhesion control method and device

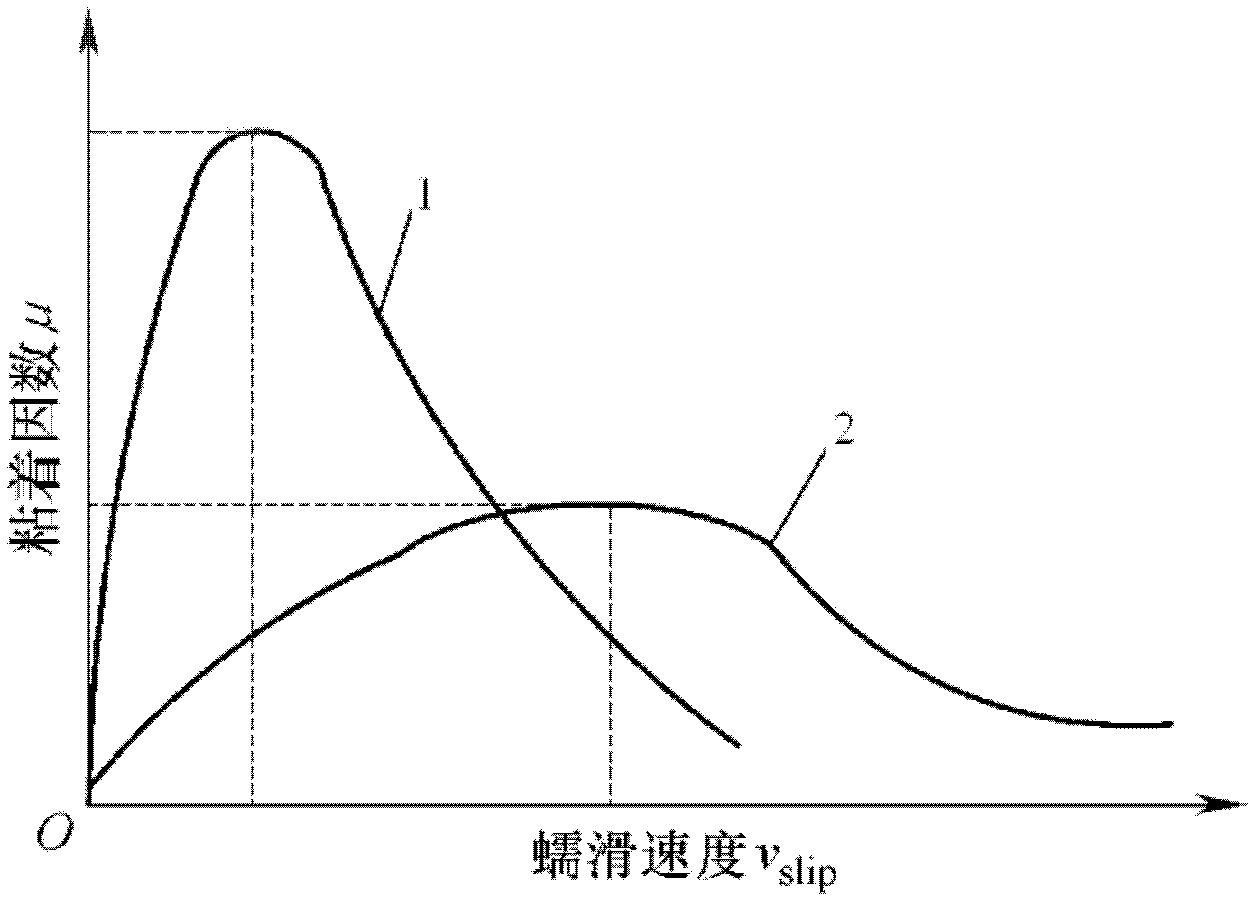

A technology of sticky control and electric locomotives, applied in locomotives, adaptive control, general control systems, etc., can solve the problems that affect the performance of the motor control system, cannot be eliminated, and the system stability and robustness are poor, so as to achieve strong robustness and the ability to deal with uncertainty, improve sticky utilization, and achieve optimal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

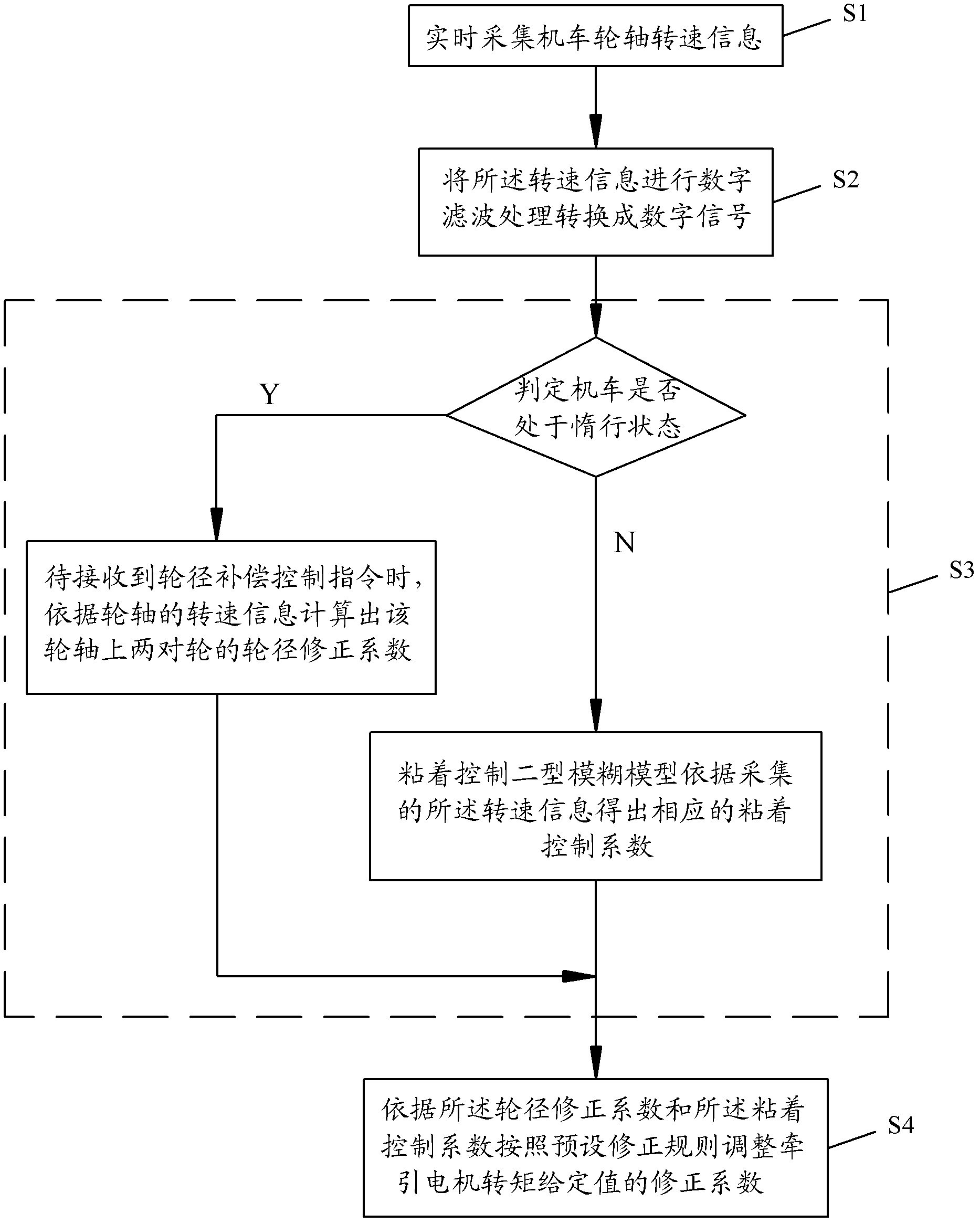

[0031] Such as Figure 4 As shown, the schematic flow chart of Embodiment 2 of the adhesion control method for electric locomotive provided by the present invention. Based on Embodiment 1, this embodiment also includes the following steps:

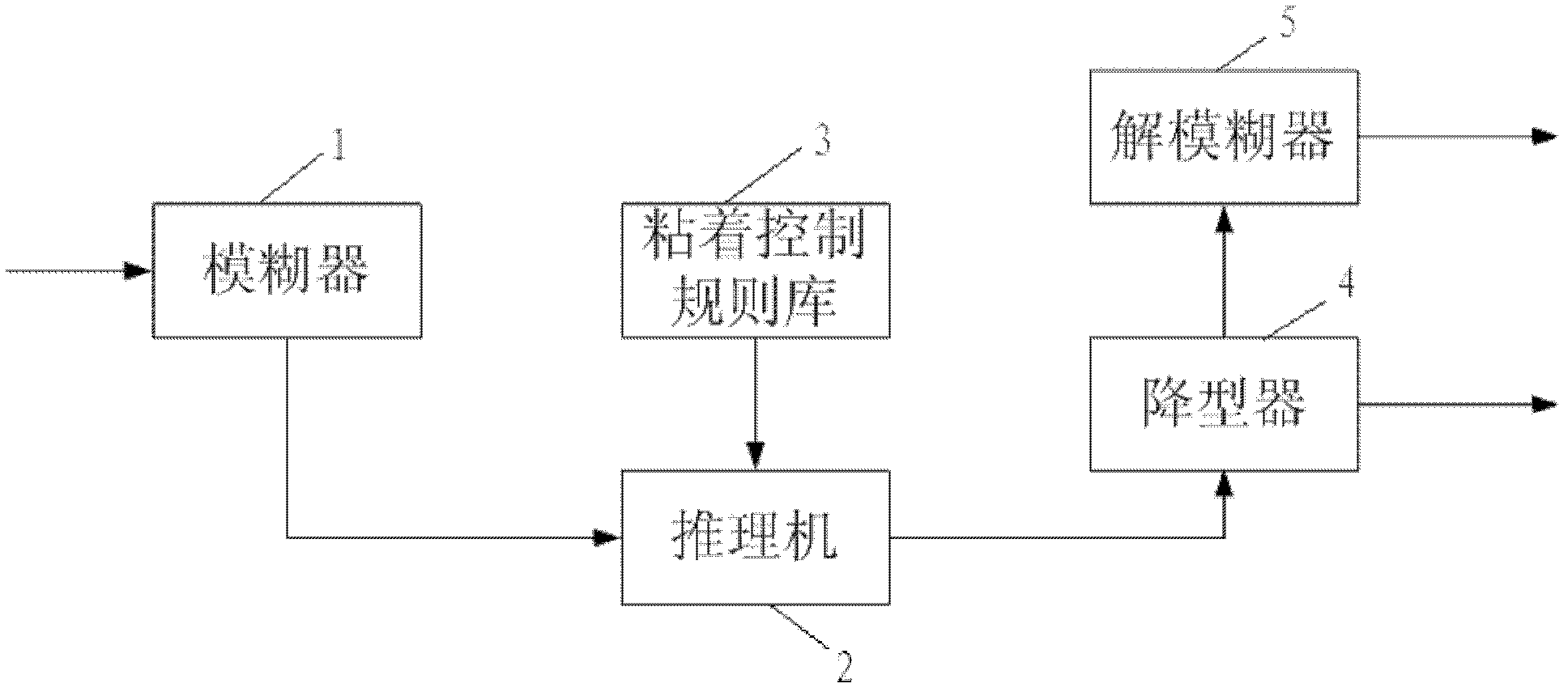

[0032] Step a1, according to locomotive operating parameters, locomotive operating environment parameters and locomotive traction structural factors to create adhesion control type II fuzzy model;

[0033] Step a2. According to the current locomotive operation situation, it is necessary to assign initial values to the parameters in the sticking control type II fuzzy model, wherein the parameters are any one or any of the acceleration threshold, creep speed threshold and creep rate combination.

[0034] By adding the two steps described in this embodiment, the adhesion control type II fuzzy model can be recreated based on actual operating experience or newly discovered influencing factors, so that the adhesion control method for electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com